Extrusion blow molding (EBM) for polypropylene PET offers a cost-effective and efficient process ideal for producing large, hollow containers with uniform wall thickness, whereas injection stretch blow molding (ISBM) delivers superior clarity, strength, and precise control over the bottle's orientation and mechanical properties. EBM involves extruding a parison that is inflated into a mold, suitable for simpler designs, while ISBM uses a preform stretched biaxially during blowing, enhancing the polymer's crystallinity and improving barrier properties. Choosing between EBM and ISBM depends on the required product performance, complexity, and production volume for polypropylene PET packaging applications.

Table of Comparison

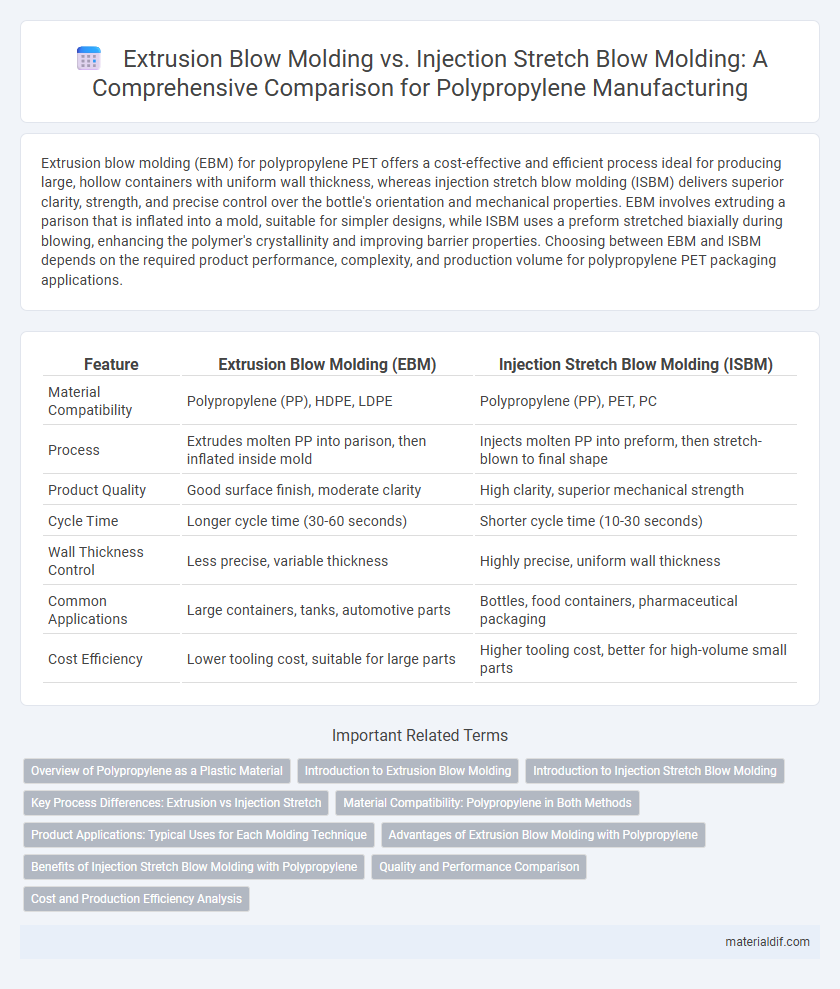

| Feature | Extrusion Blow Molding (EBM) | Injection Stretch Blow Molding (ISBM) |

|---|---|---|

| Material Compatibility | Polypropylene (PP), HDPE, LDPE | Polypropylene (PP), PET, PC |

| Process | Extrudes molten PP into parison, then inflated inside mold | Injects molten PP into preform, then stretch-blown to final shape |

| Product Quality | Good surface finish, moderate clarity | High clarity, superior mechanical strength |

| Cycle Time | Longer cycle time (30-60 seconds) | Shorter cycle time (10-30 seconds) |

| Wall Thickness Control | Less precise, variable thickness | Highly precise, uniform wall thickness |

| Common Applications | Large containers, tanks, automotive parts | Bottles, food containers, pharmaceutical packaging |

| Cost Efficiency | Lower tooling cost, suitable for large parts | Higher tooling cost, better for high-volume small parts |

Overview of Polypropylene as a Plastic Material

Polypropylene is a versatile thermoplastic polymer widely used in both extrusion blow molding and injection stretch blow molding processes due to its excellent chemical resistance, low density, and high melting point around 160degC. Extrusion blow molding provides cost-effective production for hollow parts like containers with moderate clarity, while injection stretch blow molding offers enhanced strength and optical clarity by stretching the polypropylene biaxially during molding. The material's inherent durability and flexibility make it an ideal candidate for applications requiring lightweight, impact-resistant packaging.

Introduction to Extrusion Blow Molding

Extrusion blow molding (EBM) is a manufacturing process that shapes hollow plastic parts by extruding a molten polymer tube, or parison, which is then inflated inside a mold cavity to form the desired shape. Polypropylene, favored for its chemical resistance and toughness, is commonly used in EBM to produce containers, automotive parts, and household items. Compared to injection stretch blow molding, EBM offers greater design flexibility and cost-effectiveness for larger, less complex hollow products.

Introduction to Injection Stretch Blow Molding

Injection Stretch Blow Molding (ISBM) is a manufacturing process designed for producing lightweight and high-strength hollow plastic containers, primarily used in packaging applications. This technique involves injecting molten polypropylene into a preform mold, then mechanically stretching it before blow molding to enhance molecular orientation and improve material properties such as clarity and tensile strength. ISBM is ideal for creating complex shapes with precise dimensional control, making it superior to traditional extrusion blow molding for applications requiring better visual appeal and performance.

Key Process Differences: Extrusion vs Injection Stretch

Extrusion blow molding involves melting polypropylene and extruding it into a hollow tube called a parison, which is then clamped into a mold and inflated to form the final shape. Injection stretch blow molding starts with injecting polypropylene into a preform mold, followed by heating, stretching, and blowing the preform into its final container shape, enhancing material orientation and strength. The key process difference lies in extrusion producing a continuous parison for molding, while injection stretch uses a solid preform that is mechanically stretched before blowing, resulting in improved clarity and mechanical properties.

Material Compatibility: Polypropylene in Both Methods

Polypropylene exhibits high thermal stability and chemical resistance, making it compatible with both extrusion blow molding (EBM) and injection stretch blow molding (ISBM) processes. EBM utilizes molten polypropylene to produce hollow parts with uniform wall thickness, ideal for large containers and industrial applications. ISBM enhances polypropylene's mechanical properties through biaxial orientation during stretching, resulting in improved clarity and strength for lightweight, high-quality packaging.

Product Applications: Typical Uses for Each Molding Technique

Extrusion Blow Molding is commonly used for manufacturing hollow products such as containers, bottles, and large industrial drums due to its ability to create strong, durable walls with consistent thickness. Injection Stretch Blow Molding excels in producing high-clarity, lightweight bottles for beverages and pharmaceuticals, offering precise dimensional control and enhanced material properties like improved tensile strength. Each technique suits specific applications based on product requirements such as clarity, strength, and production volume.

Advantages of Extrusion Blow Molding with Polypropylene

Extrusion Blow Molding offers improved cost efficiency and faster cycle times when processing polypropylene, making it ideal for large-volume production of hollow parts such as containers and bottles. This method provides greater design flexibility and thicker walls, enhancing durability and chemical resistance in polypropylene products. Compared to Injection Stretch Blow Molding, it allows simpler tooling and easier material use, optimizing polypropylene's thermal and mechanical properties.

Benefits of Injection Stretch Blow Molding with Polypropylene

Injection Stretch Blow Molding (ISBM) offers superior structural integrity and enhanced clarity for polypropylene containers compared to Extrusion Blow Molding (EBM). ISBM enables biaxial orientation of polypropylene molecules, resulting in improved strength, reduced material usage, and better gas barrier properties. This process also allows for more precise control over container dimensions, making it ideal for high-performance packaging applications in the food and beverage industry.

Quality and Performance Comparison

Extrusion blow molding of polypropylene produces hollow parts with moderate dimensional accuracy and consistent wall thickness, ideal for large containers but with limited surface finish quality. Injection stretch blow molding offers superior clarity, enhanced mechanical strength, and precise dimensional control by orienting polymer chains through biaxial stretching, making it optimal for high-performance packaging. Performance-wise, injection stretch blow molded polypropylene achieves better impact resistance and barrier properties compared to extrusion blow molding.

Cost and Production Efficiency Analysis

Extrusion blow molding (EBM) typically offers lower initial tooling costs and faster cycle times, making it cost-effective for high-volume production of hollow polypropylene parts with moderate precision. Injection stretch blow molding (ISBM) incurs higher tooling expenses but provides superior material distribution and enhanced mechanical properties, resulting in better quality and performance for applications like containers requiring high clarity and strength. Production efficiency in EBM is favored when simplicity and lower capital investment are prioritized, whereas ISBM excels in producing lightweight, high-performance polypropylene products despite higher upfront costs.

Extrusion Blow Molding vs Injection Stretch Blow Molding Infographic

materialdif.com

materialdif.com