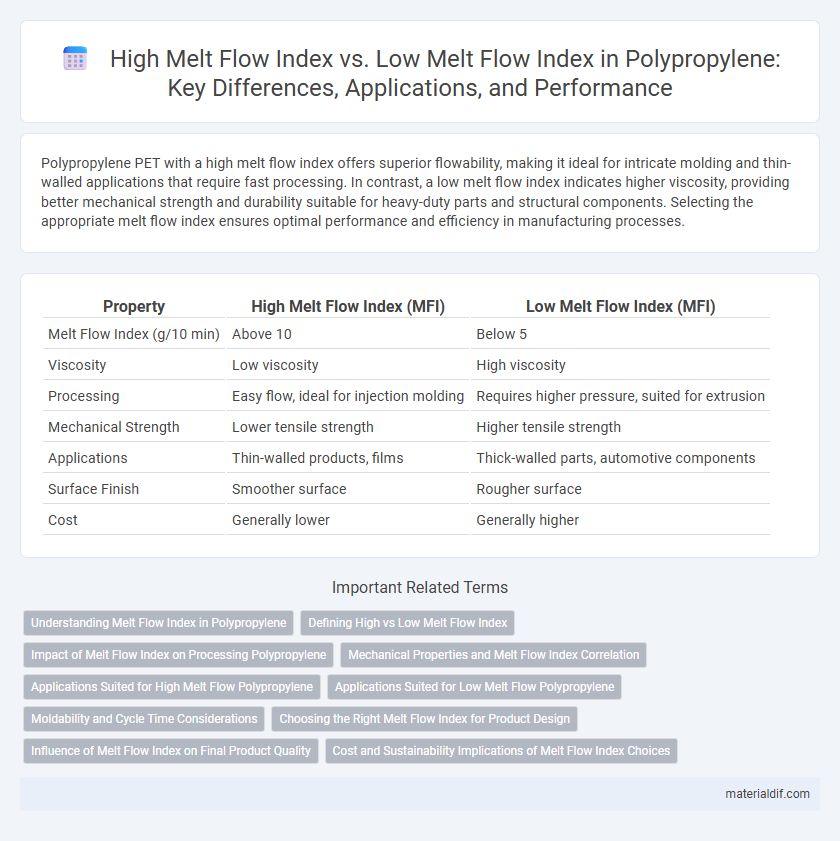

Polypropylene PET with a high melt flow index offers superior flowability, making it ideal for intricate molding and thin-walled applications that require fast processing. In contrast, a low melt flow index indicates higher viscosity, providing better mechanical strength and durability suitable for heavy-duty parts and structural components. Selecting the appropriate melt flow index ensures optimal performance and efficiency in manufacturing processes.

Table of Comparison

| Property | High Melt Flow Index (MFI) | Low Melt Flow Index (MFI) |

|---|---|---|

| Melt Flow Index (g/10 min) | Above 10 | Below 5 |

| Viscosity | Low viscosity | High viscosity |

| Processing | Easy flow, ideal for injection molding | Requires higher pressure, suited for extrusion |

| Mechanical Strength | Lower tensile strength | Higher tensile strength |

| Applications | Thin-walled products, films | Thick-walled parts, automotive components |

| Surface Finish | Smoother surface | Rougher surface |

| Cost | Generally lower | Generally higher |

Understanding Melt Flow Index in Polypropylene

Melt Flow Index (MFI) in polypropylene measures the ease of flow of the polymer melt under specific conditions, influencing processing techniques and final product properties. High MFI polypropylene indicates lower molecular weight, enabling faster flow and suitability for intricate molding applications like film or fibers, while low MFI signifies higher molecular weight, offering better mechanical strength and durability for heavier, structural parts. Understanding MFI allows manufacturers to select the appropriate polypropylene grade, balancing processing efficiency with performance requirements.

Defining High vs Low Melt Flow Index

High Melt Flow Index (MFI) polypropylene typically ranges above 10 g/10 min, indicating lower molecular weight and higher fluidity, which enhances processability in injection molding and extrusion. Low Melt Flow Index polypropylene, often below 5 g/10 min, features higher molecular weight, resulting in greater mechanical strength and impact resistance but reduced flowability. The MFI value directly influences polymer behavior during manufacturing, balancing ease of processing with the final product's physical properties.

Impact of Melt Flow Index on Processing Polypropylene

High Melt Flow Index (MFI) polypropylene exhibits lower viscosity, enabling faster and easier processing in injection molding and thin-walled applications due to better flow characteristics. Low MFI polypropylene has higher molecular weight, resulting in enhanced mechanical properties such as impact resistance and toughness but requires higher processing temperatures and pressures. Selecting the appropriate MFI grade is crucial for balancing ease of processing and desired end-use performance in polypropylene manufacturing.

Mechanical Properties and Melt Flow Index Correlation

High Melt Flow Index (MFI) polypropylene typically exhibits lower molecular weight, resulting in reduced tensile strength and impact resistance but improved processability for intricate molding applications. Conversely, Low MFI polypropylene has higher molecular weight, enhancing mechanical properties such as tensile strength, stiffness, and impact resistance, making it suitable for structural components. The correlation between Melt Flow Index and mechanical properties indicates that as MFI increases, molecular weight decreases, leading to faster flow but diminished mechanical performance.

Applications Suited for High Melt Flow Polypropylene

High melt flow index polypropylene is ideal for applications requiring easy flow into complex molds, such as thin-walled packaging, injection-molded automotive parts, and disposable consumer goods. Its lower viscosity enhances processing speed and surface finish quality, making it suitable for high-precision injection molding and extrusion processes. Industries focused on lightweight, detailed parts benefit significantly from high melt flow polypropylene due to improved moldability and reduced cycle times.

Applications Suited for Low Melt Flow Polypropylene

Low melt flow polypropylene (MFI below 5 g/10 min) offers higher molecular weight, providing enhanced mechanical strength and impact resistance ideal for injection molding of automotive parts, appliances, and reusable containers. Its slower flow characteristics enable better dimensional stability and surface finish in thick-walled products such as battery cases and industrial crates. Low MFI grades are preferred in applications requiring toughness, durability, and resistance to stress cracking under demanding conditions.

Moldability and Cycle Time Considerations

Polypropylene with a high melt flow index (MFI) offers superior moldability due to its lower viscosity, allowing for easier flow into intricate mold details and reducing cycle times significantly. Conversely, low MFI polypropylene exhibits higher viscosity, which enhances mechanical strength but can increase cycle times and challenge mold filling in complex geometries. Selecting the appropriate MFI balances production efficiency and product performance, optimizing manufacturing processes in injection molding applications.

Choosing the Right Melt Flow Index for Product Design

High Melt Flow Index (MFI) polypropylene offers greater fluidity, making it ideal for intricate injection molding and thin-wall applications requiring fast filling. Low MFI polypropylene provides higher molecular weight, resulting in improved mechanical strength and durability, suited for structural parts and impact-resistant products. Selecting the right melt flow index depends on balancing processing ease with performance demands specific to the product design and application environment.

Influence of Melt Flow Index on Final Product Quality

High Melt Flow Index (MFI) polypropylene has lower molecular weight, resulting in better flowability ideal for intricate injection molding with fine details. Low Melt Flow Index polypropylene exhibits higher molecular weight, providing superior mechanical strength and impact resistance for durable end-use products. Optimizing MFI selection directly influences product performance, surface finish, and dimensional stability in manufacturing processes.

Cost and Sustainability Implications of Melt Flow Index Choices

High Melt Flow Index (MFI) polypropylene offers lower production costs due to faster processing speeds but may compromise material strength and durability, impacting long-term sustainability. Low MFI polypropylene ensures enhanced mechanical properties and product longevity, contributing to reduced material waste and greater environmental benefits despite higher upfront manufacturing expenses. Selecting the appropriate MFI balances cost efficiency with sustainable outcomes by aligning melt flow properties with specific application requirements and lifecycle considerations.

High Melt Flow Index vs Low Melt Flow Index Infographic

materialdif.com

materialdif.com