Impact modified polypropylene exhibits enhanced toughness and improved resistance to cracking compared to unmodified polypropylene, making it ideal for applications requiring greater durability. The modification typically involves the incorporation of elastomers or rubber-like materials that absorb and dissipate energy during impact. Unmodified polypropylene, while offering excellent chemical resistance and stiffness, tends to be more brittle and less suitable for high-impact environments.

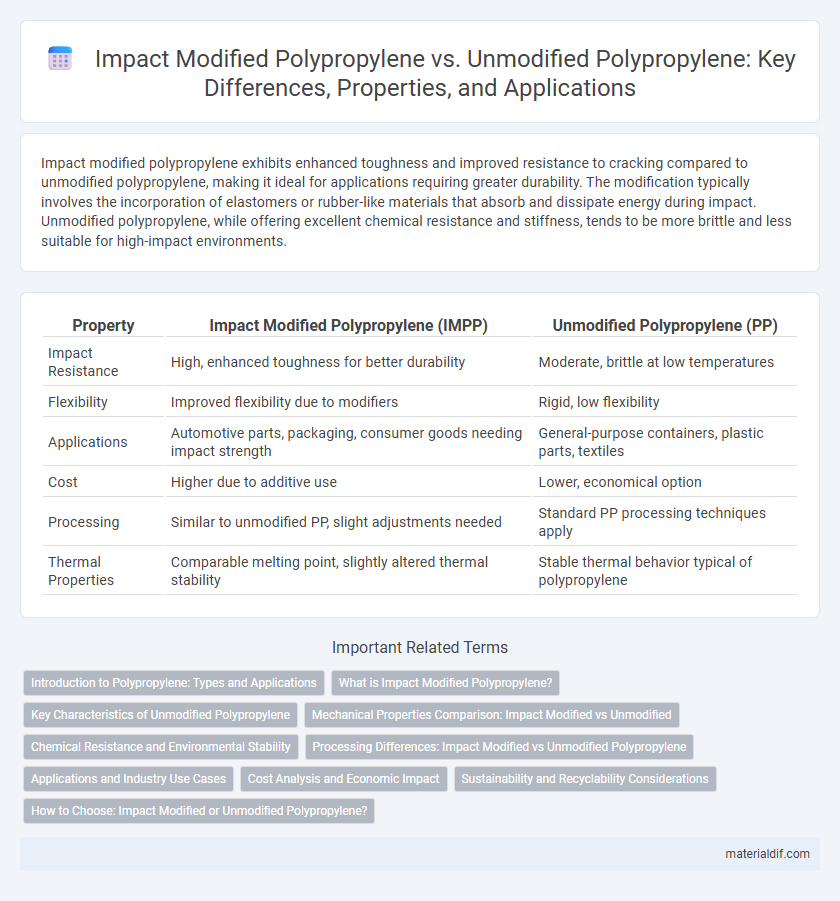

Table of Comparison

| Property | Impact Modified Polypropylene (IMPP) | Unmodified Polypropylene (PP) |

|---|---|---|

| Impact Resistance | High, enhanced toughness for better durability | Moderate, brittle at low temperatures |

| Flexibility | Improved flexibility due to modifiers | Rigid, low flexibility |

| Applications | Automotive parts, packaging, consumer goods needing impact strength | General-purpose containers, plastic parts, textiles |

| Cost | Higher due to additive use | Lower, economical option |

| Processing | Similar to unmodified PP, slight adjustments needed | Standard PP processing techniques apply |

| Thermal Properties | Comparable melting point, slightly altered thermal stability | Stable thermal behavior typical of polypropylene |

Introduction to Polypropylene: Types and Applications

Impact modified polypropylene enhances toughness and impact resistance compared to unmodified polypropylene, making it ideal for automotive parts, packaging, and consumer goods where durability is critical. Unmodified polypropylene offers excellent chemical resistance, stiffness, and heat resistance, commonly used in applications such as containers, fibers, and household products. Selection between impact modified and unmodified polypropylene depends on performance requirements in terms of flexibility, strength, and end-use environment.

What is Impact Modified Polypropylene?

Impact Modified Polypropylene (IMP) is a type of polypropylene resin enhanced with elastomers or rubber modifiers to improve its impact resistance and toughness. Unlike unmodified polypropylene, which tends to be brittle under stress or low temperatures, IMP offers greater durability and flexibility, making it ideal for demanding applications such as automotive parts and packaging. The addition of impact modifiers significantly enhances the material's ability to absorb energy without cracking or breaking.

Key Characteristics of Unmodified Polypropylene

Unmodified polypropylene exhibits high stiffness, excellent chemical resistance, and superior dimensional stability, making it ideal for applications requiring rigidity and durability. It has a relatively high melting point of around 160degC and low moisture absorption, contributing to its strength and longevity in various environmental conditions. The material's low impact resistance and brittleness at low temperatures distinguish it from impact modified polypropylene, which enhances toughness for more demanding applications.

Mechanical Properties Comparison: Impact Modified vs Unmodified

Impact modified polypropylene exhibits significantly enhanced impact resistance compared to unmodified polypropylene, making it more suitable for applications requiring higher toughness and durability. The addition of elastomeric modifiers in impact modified polypropylene improves its elongation at break and energy absorption under sudden loads, whereas unmodified polypropylene tends to be more brittle and prone to cracking. Tensile strength and stiffness in unmodified polypropylene are generally higher, but the trade-off is lower resistance to impact-related mechanical failure.

Chemical Resistance and Environmental Stability

Impact modified polypropylene contains elastomeric additives that enhance its toughness and resistance to cracking under stress, whereas unmodified polypropylene offers superior chemical resistance due to its purer polymer composition. The chemical resistance of unmodified polypropylene makes it ideal for applications involving aggressive solvents and acids, while impact modified variants maintain better environmental stability, especially in low temperatures and dynamic mechanical conditions. Both types exhibit excellent resistance to moisture and many chemicals, but selecting between them depends on the balance needed between impact performance and chemical durability.

Processing Differences: Impact Modified vs Unmodified Polypropylene

Impact modified polypropylene exhibits enhanced melt flow characteristics compared to unmodified polypropylene, facilitating easier processing in injection molding applications. The presence of impact modifiers alters the polymer's viscosity, requiring adjustments in processing temperature and shear rates to optimize flow and minimize degradation. Unmodified polypropylene typically processes at higher temperatures and exhibits lower melt strength, making it less suitable for complex or thin-walled components.

Applications and Industry Use Cases

Impact modified polypropylene offers enhanced toughness and resistance to impact, making it suitable for automotive components, packaging materials, and consumer goods requiring durability under stress. Unmodified polypropylene is widely used in applications where chemical resistance, moisture barrier properties, and flexibility are prioritized, such as in medical devices, food containers, and textile fibers. Industries like automotive, packaging, healthcare, and consumer products leverage impact modified polypropylene for structural parts, while unmodified variants dominate in lightweight, cost-effective applications.

Cost Analysis and Economic Impact

Impact modified polypropylene typically incurs higher production costs due to the incorporation of elastomers or rubber additives enhancing toughness, influencing raw material expenses and processing parameters. Economically, the improved durability and resistance reduce long-term maintenance and replacement costs in applications like automotive parts and packaging, resulting in a favorable total cost of ownership despite the initial price premium. Unmodified polypropylene offers lower upfront costs but may lead to increased failure rates and higher lifecycle costs in impact-critical applications, affecting overall economic efficiency.

Sustainability and Recyclability Considerations

Impact modified polypropylene contains elastomeric additives that improve toughness but can complicate recycling due to the presence of heterogeneous materials. Unmodified polypropylene offers straightforward recyclability and is more sustainable in circular economy models because it consists of a uniform polymer structure. Choosing unmodified polypropylene reduces contamination risks in recycling streams, enhancing material recovery efficiency and environmental benefits.

How to Choose: Impact Modified or Unmodified Polypropylene?

Selecting between impact modified polypropylene and unmodified polypropylene depends on the application's mechanical stress requirements and environmental conditions. Impact modified polypropylene incorporates rubber or elastomeric additives, enhancing toughness and resistance to impact, making it ideal for automotive parts or packaging requiring durability. Unmodified polypropylene offers higher stiffness and chemical resistance, suitable for applications with minimal impact stress and where rigidity or chemical stability is critical.

Impact Modified Polypropylene vs Unmodified Polypropylene Infographic

materialdif.com

materialdif.com