Clarified polypropylene offers enhanced clarity and a smoother surface finish compared to non-clarified polypropylene, making it ideal for applications requiring a transparent appearance. Non-clarified polypropylene typically has a more opaque look and may exhibit a rougher texture, which can be advantageous for products needing higher opacity and durability. Selecting between clarified and non-clarified polypropylene depends on the specific demand for visual aesthetics versus structural performance in pet-related uses.

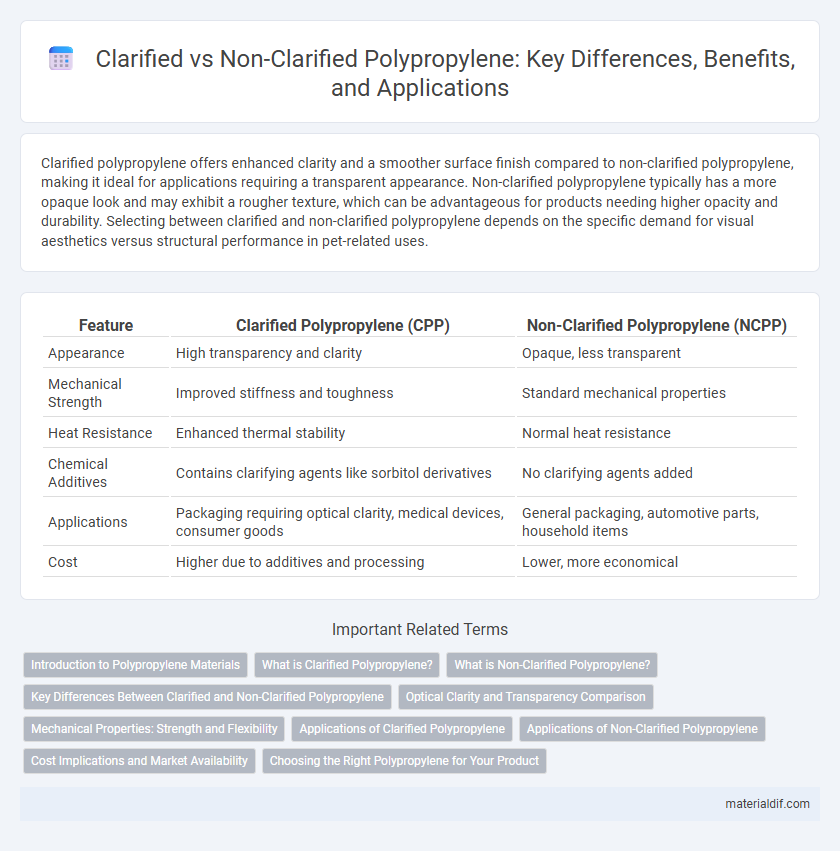

Table of Comparison

| Feature | Clarified Polypropylene (CPP) | Non-Clarified Polypropylene (NCPP) |

|---|---|---|

| Appearance | High transparency and clarity | Opaque, less transparent |

| Mechanical Strength | Improved stiffness and toughness | Standard mechanical properties |

| Heat Resistance | Enhanced thermal stability | Normal heat resistance |

| Chemical Additives | Contains clarifying agents like sorbitol derivatives | No clarifying agents added |

| Applications | Packaging requiring optical clarity, medical devices, consumer goods | General packaging, automotive parts, household items |

| Cost | Higher due to additives and processing | Lower, more economical |

Introduction to Polypropylene Materials

Clarified polypropylene offers enhanced transparency and improved aesthetic qualities compared to non-clarified polypropylene, which typically appears more opaque and less visually appealing. The clarification process increases the material's optical clarity by reducing crystallinity, making it suitable for applications requiring better light transmission and clarity. Non-clarified polypropylene retains higher opacity and is often preferred for uses prioritizing cost efficiency and impact resistance.

What is Clarified Polypropylene?

Clarified polypropylene (CPP) is a type of polypropylene that undergoes a special additive treatment to improve its optical clarity, making it more transparent than standard polypropylene. This enhancement allows CPP to be widely used in packaging applications where product visibility is essential, such as food wrapping and labeling. In contrast, non-clarified polypropylene retains a more opaque and cloudy appearance, limiting its use where transparency is critical.

What is Non-Clarified Polypropylene?

Non-clarified polypropylene is a type of polypropylene that lacks additives used to enhance transparency, resulting in a more opaque appearance. It retains the material's natural properties such as chemical resistance, durability, and flexibility but does not provide the visual clarity found in clarified polypropylene. This form is commonly used in applications where aesthetic transparency is not critical, such as in packaging, automotive parts, and industrial components.

Key Differences Between Clarified and Non-Clarified Polypropylene

Clarified polypropylene offers enhanced optical transparency and improved gloss compared to non-clarified polypropylene, making it ideal for packaging and consumer products requiring visual appeal. Non-clarified polypropylene retains a more opaque appearance with superior impact resistance and cost-effectiveness, suitable for automotive parts and industrial applications. The choice between clarified and non-clarified polypropylene depends on balancing clarity needs against mechanical strength and budget constraints.

Optical Clarity and Transparency Comparison

Clarified polypropylene exhibits significantly higher optical clarity with light transmission rates often exceeding 85%, making it ideal for applications requiring transparency. Non-clarified polypropylene typically shows a hazier, opaque appearance due to the presence of crystalline regions scattering light. Enhanced transparency in clarified polypropylene results from the removal of nucleating agents that reduce crystal size, optimizing its visual and functional appeal in packaging and consumer products.

Mechanical Properties: Strength and Flexibility

Clarified polypropylene exhibits higher tensile strength and improved stiffness compared to non-clarified polypropylene due to its enhanced molecular orientation and reduced crystallinity. Non-clarified polypropylene generally offers greater flexibility and impact resistance, making it suitable for applications requiring elasticity and toughness. The choice between clarified and non-clarified polypropylene depends on the specific mechanical property demands such as rigidity versus flexibility.

Applications of Clarified Polypropylene

Clarified polypropylene offers enhanced transparency and improved stiffness, making it ideal for packaging applications such as food containers, cosmetic bottles, and pharmaceutical blister packs. Its superior optical clarity allows brands to showcase product visibility while maintaining chemical resistance and durability. The material's lightweight nature also benefits the automotive industry for interior components where aesthetics and functional performance are essential.

Applications of Non-Clarified Polypropylene

Non-clarified polypropylene is widely used in automotive parts, packaging, and consumer goods due to its excellent chemical resistance and durability. Its opaque nature provides UV protection, making it ideal for outdoor applications and household items. This type also exhibits superior impact resistance, which is critical for industrial components and protective gear.

Cost Implications and Market Availability

Clarified polypropylene typically commands a higher price due to additional processing steps that enhance transparency and optical properties, impacting overall manufacturing costs. Non-clarified polypropylene is more widely available on the market and generally offers a cost-effective solution for applications where clarity is not critical. Market availability of clarified polypropylene is comparatively limited, often reserved for specialized uses in packaging and consumer goods where visual appeal and material performance justify the premium.

Choosing the Right Polypropylene for Your Product

Clarified polypropylene offers enhanced transparency and improved aesthetic appeal, making it ideal for packaging and consumer products where visual clarity is crucial. Non-clarified polypropylene provides superior impact resistance and cost-effectiveness, suited for industrial applications requiring durability over appearance. Assessing product requirements such as clarity, mechanical strength, and budget will guide the selection between clarified and non-clarified polypropylene types.

Clarified Polypropylene vs Non-Clarified Polypropylene Infographic

materialdif.com

materialdif.com