Clarified polypropylene (PP) exhibits enhanced transparency and improved optical properties compared to unfilled PP, making it ideal for applications requiring clear or translucent materials. Unfilled PP generally offers superior flexibility and impact resistance due to the absence of fillers that might increase brittleness. Selecting between clarified and unfilled PP depends on the need for visual clarity versus mechanical performance in polypropylene products.

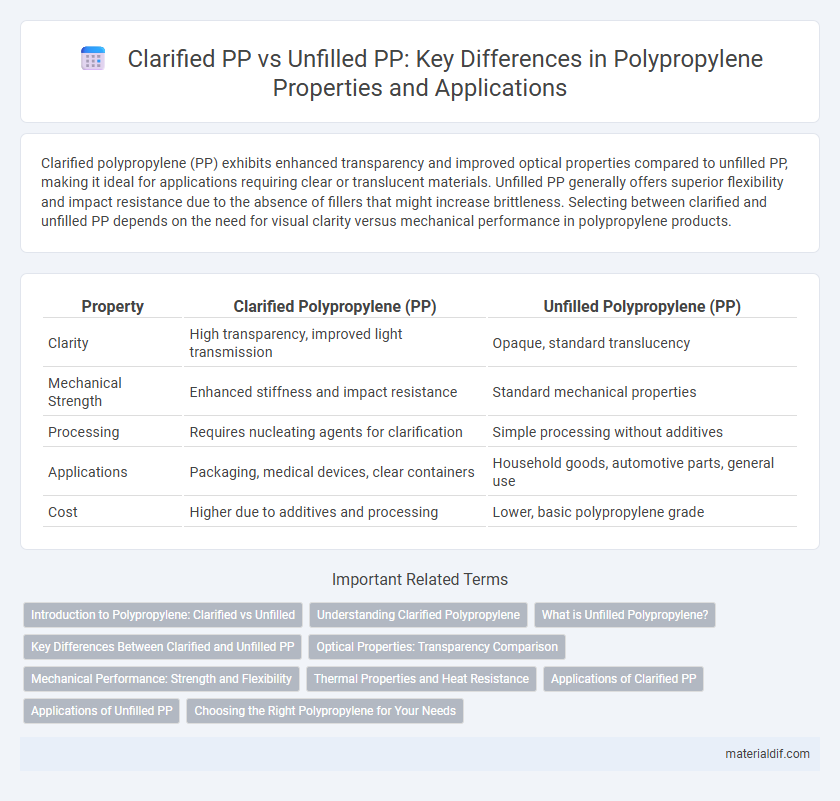

Table of Comparison

| Property | Clarified Polypropylene (PP) | Unfilled Polypropylene (PP) |

|---|---|---|

| Clarity | High transparency, improved light transmission | Opaque, standard translucency |

| Mechanical Strength | Enhanced stiffness and impact resistance | Standard mechanical properties |

| Processing | Requires nucleating agents for clarification | Simple processing without additives |

| Applications | Packaging, medical devices, clear containers | Household goods, automotive parts, general use |

| Cost | Higher due to additives and processing | Lower, basic polypropylene grade |

Introduction to Polypropylene: Clarified vs Unfilled

Polypropylene (PP) is a versatile thermoplastic polymer widely used in packaging, automotive, and consumer goods industries due to its excellent chemical resistance and mechanical properties. Clarified PP is enhanced with special additives that increase transparency by reducing crystallinity, making it ideal for applications requiring optical clarity. Unfilled PP, in contrast, offers higher impact resistance and processability but remains opaque, suited for structural and molded parts where transparency is not critical.

Understanding Clarified Polypropylene

Clarified polypropylene (PP) undergoes a nucleation process that enhances its optical clarity, resulting in higher transparency compared to unfilled PP, which typically appears hazy or translucent. The addition of clarifying agents improves crystallinity by controlling spherulite size, leading to a more uniform and clearer material structure. This modification not only boosts aesthetic appeal but also maintains the inherent mechanical strength and chemical resistance of polypropylene.

What is Unfilled Polypropylene?

Unfilled polypropylene is a type of polypropylene resin that lacks added fillers or reinforcing materials, resulting in a pure polymer matrix. It exhibits high clarity, good chemical resistance, and excellent flexibility, making it suitable for applications such as packaging, medical devices, and consumer goods. Unlike clarified PP, which is enhanced for improved optical properties, unfilled polypropylene maintains its natural semi-crystalline structure and balanced mechanical performance.

Key Differences Between Clarified and Unfilled PP

Clarified polypropylene (PP) contains a clarifying agent that improves transparency and optical properties, making it suitable for applications requiring clear or translucent materials. Unfilled PP lacks additives, resulting in a more opaque appearance and typically higher impact resistance but lower stiffness compared to clarified variants. Key differences lie in clarity, mechanical properties, and processing conditions, with clarified PP offering enhanced visual appeal while unfilled PP provides better toughness and cost efficiency.

Optical Properties: Transparency Comparison

Clarified polypropylene (PP) exhibits significantly enhanced optical properties compared to unfilled PP, offering greater transparency and reduced haze due to the use of clarifying agents that refine the polymer's crystalline structure. This modification results in a clearer, glossier appearance ideal for applications requiring visual appeal, such as packaging and automotive parts. Unfilled PP, with its higher crystallinity and lack of additives, generally appears more opaque and exhibits lower light transmission.

Mechanical Performance: Strength and Flexibility

Clarified polypropylene (PP) exhibits enhanced mechanical performance with higher tensile strength and improved stiffness compared to unfilled PP due to the presence of clarifying agents that refine the polymer's crystalline structure. Unfilled PP offers greater flexibility and impact resistance but generally has lower modulus and tensile strength, making it suitable for applications requiring more ductility. Clarified PP excels in strength-critical uses like automotive parts, while unfilled PP is preferred for flexible packaging and components needing better elongation.

Thermal Properties and Heat Resistance

Clarified polypropylene (PP) exhibits enhanced thermal properties compared to unfilled PP, featuring a higher heat deflection temperature (HDT) typically around 120-130degC, which improves dimensional stability under heat. The addition of clarifying agents reduces the crystallite size, resulting in increased transparency and better thermal conductivity, thereby boosting heat resistance. Unfilled PP generally has a lower HDT near 90-100degC and is more prone to deformation under thermal stress, limiting its applications in high-temperature environments.

Applications of Clarified PP

Clarified polypropylene (PP) offers superior optical clarity and gloss compared to unfilled PP, making it ideal for packaging applications that require high transparency, such as food containers, medical devices, and consumer goods packaging. Its enhanced aesthetic appeal and improved surface finish support branding and product visibility, while maintaining the chemical resistance and mechanical properties typical of polypropylene. This makes clarified PP a preferred choice in applications where both performance and visual quality are critical.

Applications of Unfilled PP

Unfilled polypropylene (PP) is widely used in packaging, automotive components, and consumer goods due to its excellent chemical resistance, high impact strength, and ease of processing. Its natural translucency and mechanical properties make it ideal for applications requiring durability without additional fillers, such as food containers, medical devices, and household items. Unfilled PP also provides cost efficiency and recyclability, making it a preferred choice for sustainable manufacturing in various industries.

Choosing the Right Polypropylene for Your Needs

Clarified polypropylene offers enhanced optical clarity and improved heat resistance compared to unfilled polypropylene, making it ideal for applications requiring high transparency and dimensional stability. Unfilled polypropylene provides greater flexibility and toughness at a lower cost, suitable for general-purpose uses where clarity is not essential. Selecting the right polypropylene depends on balancing the need for visual appeal and thermal performance with budget and mechanical property requirements.

Clarified PP vs Unfilled PP Infographic

materialdif.com

materialdif.com