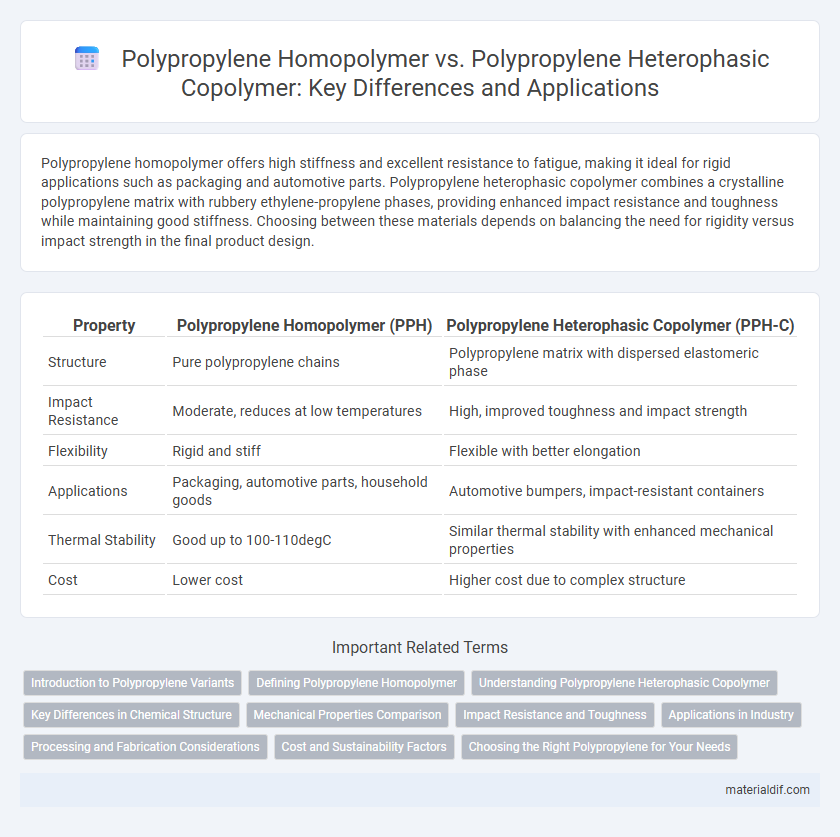

Polypropylene homopolymer offers high stiffness and excellent resistance to fatigue, making it ideal for rigid applications such as packaging and automotive parts. Polypropylene heterophasic copolymer combines a crystalline polypropylene matrix with rubbery ethylene-propylene phases, providing enhanced impact resistance and toughness while maintaining good stiffness. Choosing between these materials depends on balancing the need for rigidity versus impact strength in the final product design.

Table of Comparison

| Property | Polypropylene Homopolymer (PPH) | Polypropylene Heterophasic Copolymer (PPH-C) |

|---|---|---|

| Structure | Pure polypropylene chains | Polypropylene matrix with dispersed elastomeric phase |

| Impact Resistance | Moderate, reduces at low temperatures | High, improved toughness and impact strength |

| Flexibility | Rigid and stiff | Flexible with better elongation |

| Applications | Packaging, automotive parts, household goods | Automotive bumpers, impact-resistant containers |

| Thermal Stability | Good up to 100-110degC | Similar thermal stability with enhanced mechanical properties |

| Cost | Lower cost | Higher cost due to complex structure |

Introduction to Polypropylene Variants

Polypropylene homopolymer consists of a single type of propylene monomer, providing high rigidity, tensile strength, and chemical resistance, making it ideal for packaging and automotive applications. Polypropylene heterophasic copolymer combines crystalline polypropylene homopolymer with an elastomeric phase, enhancing impact resistance and flexibility for demanding uses such as automotive bumpers and industrial components. Both variants offer tailored mechanical properties, enabling manufacturers to select materials based on performance requirements and end-use environments.

Defining Polypropylene Homopolymer

Polypropylene homopolymer is a type of polypropylene composed solely of propylene monomers, resulting in a highly crystalline polymer with strong tensile strength and stiffness. It offers excellent chemical resistance, high melting point around 160-170degC, and is commonly used in packaging, automotive parts, and textiles. Unlike heterophasic copolymers, homopolymers lack elastomeric phases, giving them superior rigidity but lower impact resistance.

Understanding Polypropylene Heterophasic Copolymer

Polypropylene heterophasic copolymer consists of a polypropylene homopolymer matrix with dispersed ethylene-propylene rubber phases, enhancing impact resistance and toughness compared to polypropylene homopolymer. This copolymer structure balances rigidity and flexibility, making it ideal for automotive components, packaging, and appliances requiring improved mechanical performance at low temperatures. Understanding the morphology and composition of heterophasic copolymers is crucial for optimizing processing conditions and achieving desired material properties.

Key Differences in Chemical Structure

Polypropylene homopolymer consists of a repeating unit of propylene molecules arranged in a highly regular isotactic structure, resulting in high crystallinity and rigidity. Polypropylene heterophasic copolymer combines a polypropylene homopolymer matrix with a dispersed rubbery copolymer phase, typically ethylene-propylene, enhancing impact resistance and flexibility. The primary chemical difference lies in the uniform monomer composition of homopolymer versus the dual-phase structure of heterophasic copolymer, which integrates both crystalline and elastomeric segments.

Mechanical Properties Comparison

Polypropylene homopolymer exhibits high tensile strength and rigidity due to its crystalline structure, making it ideal for applications requiring stiffness and dimensional stability. Polypropylene heterophasic copolymer, incorporating elastomeric phases, offers enhanced impact resistance and flexibility while maintaining reasonable mechanical strength. The heterophasic variant's balanced mechanical properties improve toughness and elongation compared to the more brittle homopolymer.

Impact Resistance and Toughness

Polypropylene homopolymer offers high stiffness and clarity but has lower impact resistance and toughness compared to polypropylene heterophasic copolymer. Polypropylene heterophasic copolymer integrates an elastomeric phase, significantly enhancing impact strength and toughness, making it suitable for demanding applications requiring durability. The increased impact resistance of heterophasic copolymers supports improved performance in automotive parts, packaging, and consumer goods where mechanical stress is prevalent.

Applications in Industry

Polypropylene homopolymer is commonly used in packaging, automotive parts, and textiles due to its high tensile strength and rigidity. Polypropylene heterophasic copolymer, with its improved impact resistance and flexibility, finds applications in automotive bumpers, impact-resistant containers, and household appliances. Industry selects homopolymer for structural applications, while heterophasic copolymer suits products requiring enhanced durability and toughness.

Processing and Fabrication Considerations

Polypropylene homopolymer offers superior stiffness and tensile strength, making it ideal for injection molding and thermoforming processes requiring precision and rigidity. Heterophasic copolymer exhibits enhanced impact resistance and flexibility, favoring extrusion and blow molding in applications demanding toughness and durability. Processing temperatures for homopolymers typically range between 200-250degC, whereas heterophasic copolymers require slightly lower temperatures around 190-230degC to optimize flow and mechanical performance.

Cost and Sustainability Factors

Polypropylene homopolymer typically offers a lower production cost due to its simpler polymer structure and more straightforward manufacturing process compared to polypropylene heterophasic copolymer, which requires complex catalyst systems and multi-phase polymerization. However, heterophasic copolymers provide enhanced mechanical properties and impact resistance, enabling longer product lifespans and contributing to sustainability through reduced material waste and extended usage cycles. The environmental impact of polypropylene heterophasic copolymers can be mitigated by improved recyclability and energy efficiency during production, balancing their higher initial cost against lifecycle sustainability benefits.

Choosing the Right Polypropylene for Your Needs

Polypropylene homopolymer offers high rigidity, excellent chemical resistance, and a higher melting point, making it ideal for applications requiring stiffness and thermal stability. Polypropylene heterophasic copolymer combines impact resistance with good toughness at low temperatures due to its elastomeric phase, suitable for automotive parts and flexible packaging. Selecting the right polypropylene depends on balancing mechanical properties such as stiffness, impact resistance, and thermal performance with the specific demands of your application.

Polypropylene Homopolymer vs Polypropylene Heterophasic Copolymer Infographic

materialdif.com

materialdif.com