Clarified polypropylene exhibits higher transparency and improved gloss compared to unclarified polypropylene, making it ideal for applications requiring enhanced visual appeal. Unclarified polypropylene typically offers better impact resistance and cost-effectiveness due to its more opaque nature. Selecting between clarified and unclarified polypropylene depends on the balance needed between optical properties and mechanical performance in the final product.

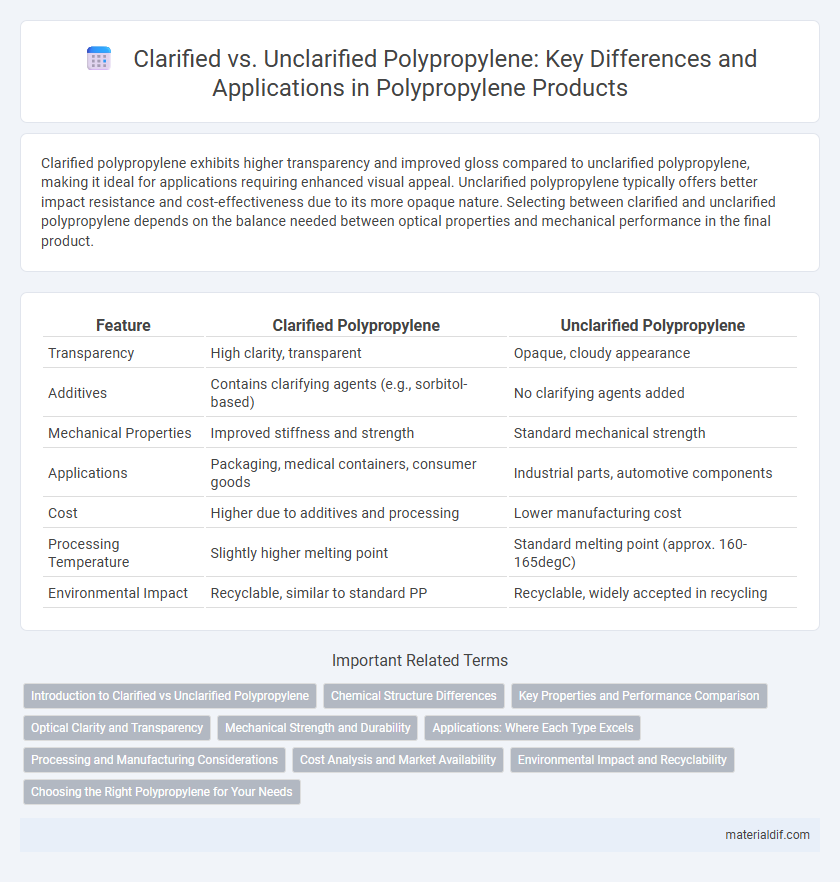

Table of Comparison

| Feature | Clarified Polypropylene | Unclarified Polypropylene |

|---|---|---|

| Transparency | High clarity, transparent | Opaque, cloudy appearance |

| Additives | Contains clarifying agents (e.g., sorbitol-based) | No clarifying agents added |

| Mechanical Properties | Improved stiffness and strength | Standard mechanical strength |

| Applications | Packaging, medical containers, consumer goods | Industrial parts, automotive components |

| Cost | Higher due to additives and processing | Lower manufacturing cost |

| Processing Temperature | Slightly higher melting point | Standard melting point (approx. 160-165degC) |

| Environmental Impact | Recyclable, similar to standard PP | Recyclable, widely accepted in recycling |

Introduction to Clarified vs Unclarified Polypropylene

Clarified polypropylene offers enhanced optical clarity and improved gloss compared to unclarified polypropylene, achieved through specialized nucleating agents that modify its crystalline structure. Unclarified polypropylene retains its natural opacity and is often chosen for applications where transparency is not critical, prioritizing cost-effectiveness and mechanical strength. The choice between clarified and unclarified polypropylene depends on the specific requirements for visual quality and functional performance in packaging, automotive parts, and consumer goods.

Chemical Structure Differences

Clarified polypropylene exhibits a more ordered crystalline structure with enhanced isotacticity, resulting in increased clarity and improved mechanical properties compared to unclarified polypropylene. Unclarified polypropylene typically contains higher levels of atactic polypropylene, leading to greater amorphous regions that scatter light and reduce transparency. The chemical structure differences, particularly the degree of tacticity and crystallinity, directly influence the optical and physical characteristics of clarified versus unclarified polypropylene.

Key Properties and Performance Comparison

Clarified polypropylene exhibits enhanced optical clarity and improved stiffness compared to unclarified polypropylene, making it ideal for applications requiring transparency and aesthetic appeal. Unclarified polypropylene, while less transparent, offers superior impact resistance and better heat deflection performance, suitable for more demanding mechanical uses. Key properties such as haze percentage, tensile strength, and melting point highlight the trade-offs between the two types, driving material selection based on specific performance needs.

Optical Clarity and Transparency

Clarified polypropylene offers superior optical clarity and enhanced transparency compared to unclarified polypropylene, making it ideal for applications requiring clear visuals such as packaging and medical containers. The clarification process reduces haze and increases light transmission, resulting in a more transparent and aesthetically appealing product. In contrast, unclarified polypropylene exhibits a higher level of opacity and haze, limiting its use in products where visual clarity is important.

Mechanical Strength and Durability

Clarified polypropylene exhibits enhanced mechanical strength and improved durability compared to unclarified polypropylene due to its increased crystallinity and reduced impurities. The clarification process results in a more uniform polymer structure, which enhances impact resistance and tensile strength, making it suitable for demanding applications. Unclarified polypropylene typically has lower mechanical performance and is more prone to environmental stress cracking and degradation over time.

Applications: Where Each Type Excels

Clarified polypropylene offers superior optical clarity, making it ideal for applications in packaging, medical devices, and consumer goods where transparency is critical. Unclarified polypropylene, with its higher impact resistance and opacity, excels in automotive parts, household appliances, and industrial components requiring durability and strength. Each type's distinct physical properties enable tailored performance across diverse sectors, optimizing material selection based on specific application needs.

Processing and Manufacturing Considerations

Clarified polypropylene offers enhanced transparency and improved printability due to the addition of clarifying agents, which can influence extrusion and injection molding parameters by requiring precise temperature control to avoid degradation of the clarifier additives. Unclarified polypropylene, being more opaque, generally allows for more flexible processing conditions with less sensitivity to temperature variations, making it easier to mold and extrude but less suitable for applications demanding optical clarity. Manufacturers must balance these considerations with the end-use requirements, as clarified grades often necessitate optimized cooling rates to achieve the desired clarity without compromising mechanical performance.

Cost Analysis and Market Availability

Clarified polypropylene generally commands a higher price than unclarified polypropylene due to additional processing steps required for enhanced optical clarity. Market availability of unclarified polypropylene is broader, with more suppliers and larger volume production, making it more accessible for cost-sensitive applications. Cost analysis reveals that while clarified polypropylene offers premium performance benefits, unclarified grades dominate in sectors prioritizing affordability and wide market supply.

Environmental Impact and Recyclability

Clarified polypropylene exhibits enhanced recyclability due to its higher purity and reduced contamination from additives, leading to more efficient recycling processes and lower environmental footprint. Unclarified polypropylene contains more pigments and fillers that can complicate recycling, often resulting in downcycling and increased environmental impact. Choosing clarified polypropylene supports sustainable material management by facilitating easier recovery and reuse in circular economy applications.

Choosing the Right Polypropylene for Your Needs

Clarified polypropylene offers enhanced transparency and improved surface gloss, making it ideal for packaging applications where product visibility is crucial. Unclarified polypropylene provides higher impact resistance and durability, suitable for automotive parts and industrial uses where strength is prioritized over clarity. Selecting the right polypropylene depends on balancing the need for visual appeal versus mechanical performance based on specific application requirements.

Clarified Polypropylene vs Unclarified Polypropylene Infographic

materialdif.com

materialdif.com