Impact-modified polypropylene offers enhanced toughness and durability compared to standard polypropylene, making it ideal for applications requiring higher impact resistance. This modification improves the material's ability to absorb energy without cracking or breaking, extending the lifespan of products such as automotive parts and packaging. Standard polypropylene remains suitable for applications where rigidity and chemical resistance are prioritized over impact strength.

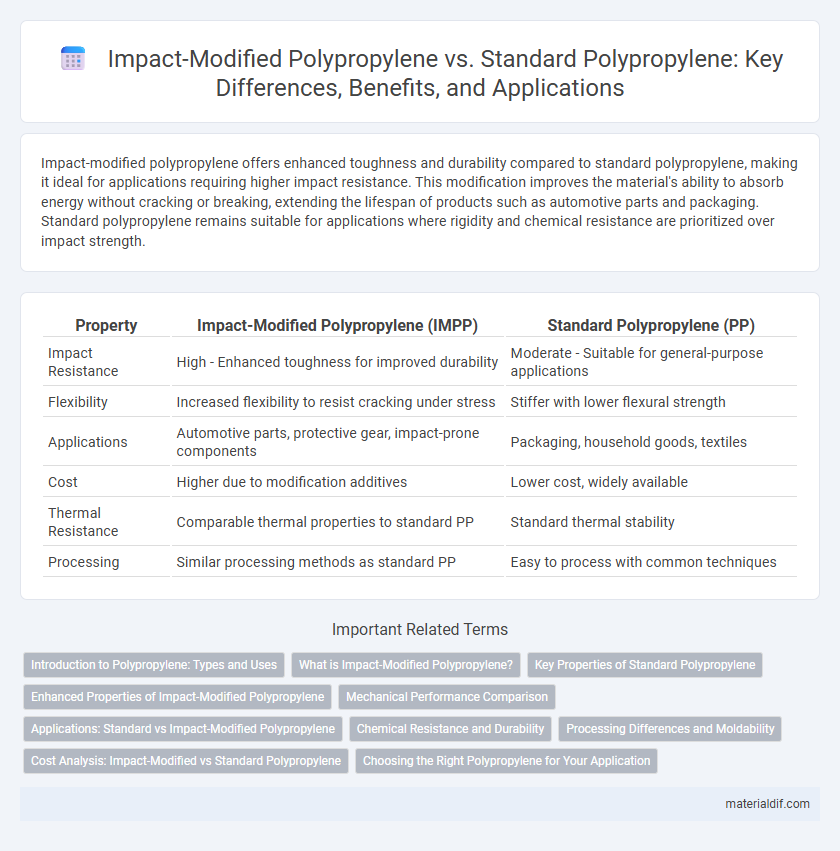

Table of Comparison

| Property | Impact-Modified Polypropylene (IMPP) | Standard Polypropylene (PP) |

|---|---|---|

| Impact Resistance | High - Enhanced toughness for improved durability | Moderate - Suitable for general-purpose applications |

| Flexibility | Increased flexibility to resist cracking under stress | Stiffer with lower flexural strength |

| Applications | Automotive parts, protective gear, impact-prone components | Packaging, household goods, textiles |

| Cost | Higher due to modification additives | Lower cost, widely available |

| Thermal Resistance | Comparable thermal properties to standard PP | Standard thermal stability |

| Processing | Similar processing methods as standard PP | Easy to process with common techniques |

Introduction to Polypropylene: Types and Uses

Impact-modified polypropylene (IMP) contains additives like ethylene-propylene rubber to enhance toughness and resistance to impact, making it ideal for automotive parts, packaging, and consumer goods requiring durability. Standard polypropylene is widely used for containers, textiles, and medical devices due to its lightweight, chemical resistance, and versatility but has lower impact resistance. Selecting between impact-modified and standard polypropylene depends on application-specific strength and flexibility requirements.

What is Impact-Modified Polypropylene?

Impact-modified polypropylene is a type of polypropylene resin enhanced with elastomers or rubber additives to improve its toughness and resistance to impact. This modification results in better performance under sudden force or stress, making it ideal for applications requiring durability and flexibility. Standard polypropylene, in contrast, lacks these additives and typically exhibits higher rigidity but lower impact resistance.

Key Properties of Standard Polypropylene

Standard polypropylene is characterized by its excellent chemical resistance, low density, and high tensile strength, making it ideal for rigid packaging and automotive components. It exhibits a melting point around 160degC and offers good fatigue resistance, although its impact strength at low temperatures is limited. The material's rigidity and dimensional stability support applications requiring structural integrity without exposure to extreme stress or impact.

Enhanced Properties of Impact-Modified Polypropylene

Impact-modified polypropylene incorporates elastomers or rubber-like additives, significantly improving its toughness and resistance to impact compared to standard polypropylene. This enhanced material displays superior performance in applications requiring durability and flexibility, such as automotive parts and packaging. Impact-modified polypropylene also maintains good chemical resistance and processability, making it a versatile choice for demanding industrial uses.

Mechanical Performance Comparison

Impact-modified polypropylene exhibits enhanced toughness and improved impact resistance compared to standard polypropylene, making it more suitable for applications requiring higher durability under stress. The incorporation of elastomeric modifiers in impact-modified polypropylene significantly increases elongation at break and reduces brittleness without compromising tensile strength. Standard polypropylene offers higher rigidity and stiffness but is more prone to cracking under sudden impact loads, limiting its use in dynamic or high-impact environments.

Applications: Standard vs Impact-Modified Polypropylene

Impact-modified polypropylene (IMPP) is preferred in applications requiring enhanced toughness and resistance to impact, such as automotive bumpers, protective equipment, and packaging materials subjected to rough handling. Standard polypropylene is commonly used in applications like food containers, textile fibers, and household goods where high stiffness and chemical resistance are more critical than impact resistance. The choice between impact-modified and standard polypropylene depends on specific performance requirements, balancing durability with cost-effectiveness in product design.

Chemical Resistance and Durability

Impact-modified polypropylene exhibits enhanced durability compared to standard polypropylene due to the incorporation of impact modifiers that improve toughness without compromising chemical resistance. Both grades maintain strong resistance to acids, bases, and solvents, but impact-modified polypropylene is better suited for applications involving repeated mechanical stress or low-temperature environments. The improved impact strength combined with retained chemical resistance makes impact-modified polypropylene ideal for automotive parts and protective containers exposed to harsh conditions.

Processing Differences and Moldability

Impact-modified polypropylene exhibits enhanced toughness due to the incorporation of elastomeric modifiers, which affects its melt flow behavior compared to standard polypropylene, requiring adjusted processing parameters such as lower injection speeds and increased mold temperatures to prevent defects. Its improved impact resistance allows for thinner wall sections and more complex geometries in molded parts, offering greater design flexibility and reduced cycle times due to better flowability under optimized conditions. Standard polypropylene, with higher stiffness but lower impact strength, processes more efficiently at higher temperatures and speeds but is limited in moldability for applications demanding high toughness or intricate designs.

Cost Analysis: Impact-Modified vs Standard Polypropylene

Impact-modified polypropylene typically incurs higher material costs than standard polypropylene due to the inclusion of elastomeric additives designed to enhance toughness and impact resistance. The increased cost is often offset by reduced product failures, leading to lower long-term maintenance and replacement expenses. Cost analysis must balance initial investment against performance benefits in applications requiring enhanced durability.

Choosing the Right Polypropylene for Your Application

Impact-modified polypropylene offers enhanced toughness and resistance to cracking under stress compared to standard polypropylene, making it ideal for applications requiring durability and impact resistance such as automotive parts and industrial components. Standard polypropylene provides excellent chemical resistance, tensile strength, and cost-effectiveness, suitable for packaging, consumer goods, and household items where impact resistance is less critical. Selecting the right polypropylene depends on balancing factors like mechanical performance, environmental resistance, and budget to meet specific application demands.

Impact-Modified Polypropylene vs Standard Polypropylene Infographic

materialdif.com

materialdif.com