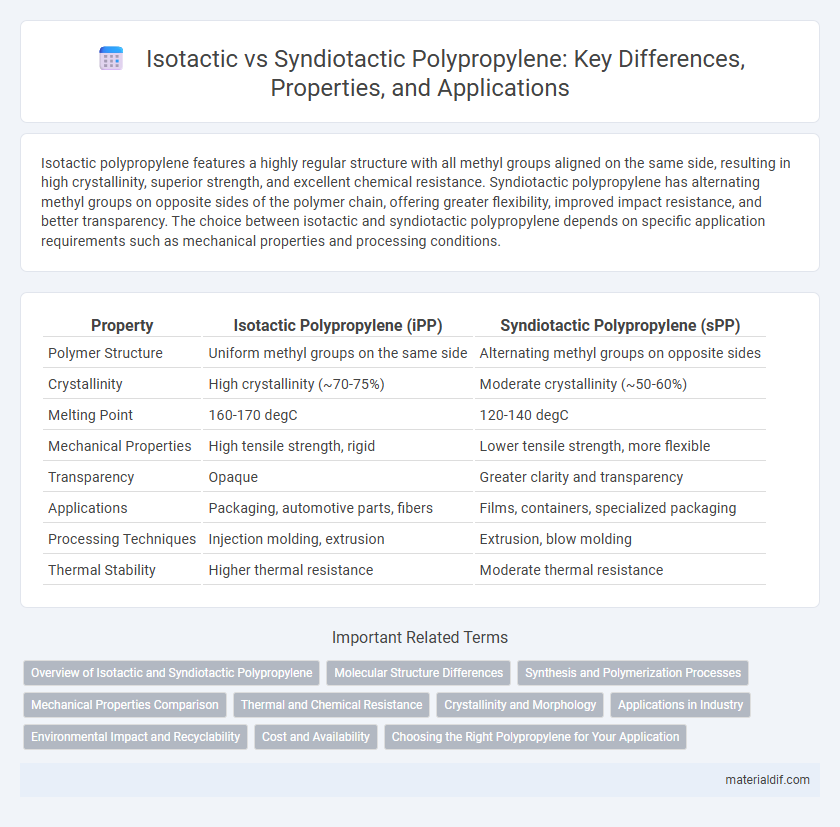

Isotactic polypropylene features a highly regular structure with all methyl groups aligned on the same side, resulting in high crystallinity, superior strength, and excellent chemical resistance. Syndiotactic polypropylene has alternating methyl groups on opposite sides of the polymer chain, offering greater flexibility, improved impact resistance, and better transparency. The choice between isotactic and syndiotactic polypropylene depends on specific application requirements such as mechanical properties and processing conditions.

Table of Comparison

| Property | Isotactic Polypropylene (iPP) | Syndiotactic Polypropylene (sPP) |

|---|---|---|

| Polymer Structure | Uniform methyl groups on the same side | Alternating methyl groups on opposite sides |

| Crystallinity | High crystallinity (~70-75%) | Moderate crystallinity (~50-60%) |

| Melting Point | 160-170 degC | 120-140 degC |

| Mechanical Properties | High tensile strength, rigid | Lower tensile strength, more flexible |

| Transparency | Opaque | Greater clarity and transparency |

| Applications | Packaging, automotive parts, fibers | Films, containers, specialized packaging |

| Processing Techniques | Injection molding, extrusion | Extrusion, blow molding |

| Thermal Stability | Higher thermal resistance | Moderate thermal resistance |

Overview of Isotactic and Syndiotactic Polypropylene

Isotactic polypropylene features a highly regular structure with all methyl groups aligned on the same side, resulting in a semicrystalline polymer with high tensile strength and excellent chemical resistance. Syndiotactic polypropylene has alternating methyl group placement along the polymer chain, producing a softer material with enhanced transparency and impact toughness due to its lower crystallinity. Both forms are widely used in packaging, automotive parts, and consumer goods, with isotactic favored for rigidity and syndiotactic preferred for flexibility and optical clarity.

Molecular Structure Differences

Isotactic polypropylene features a molecular structure where all methyl groups are aligned on the same side of the polymer backbone, resulting in a highly crystalline and rigid material. Syndiotactic polypropylene has an alternating arrangement of methyl groups on opposite sides of the chain, which leads to increased flexibility and different thermal properties. These distinct stereoregular configurations significantly influence the polymer's mechanical strength, melting point, and chemical resistance.

Synthesis and Polymerization Processes

Isotactic polypropylene is synthesized using Ziegler-Natta or metallocene catalysts that promote uniform stereoregularity, resulting in all methyl groups aligned on the same side of the polymer chain. Syndiotactic polypropylene is produced through polymerization with specific metallocene catalysts that alternate the configuration of methyl groups along the backbone, creating a regular alternating pattern. The choice of catalyst and polymerization conditions, such as temperature and pressure, critically influence the tacticity and crystallinity of the resulting polymer.

Mechanical Properties Comparison

Isotactic polypropylene exhibits higher tensile strength and stiffness due to its highly regular molecular arrangement, which promotes crystallinity and enhances rigidity. Syndiotactic polypropylene offers improved impact resistance and flexibility, attributed to its alternating stereochemistry that reduces crystallinity and allows for greater molecular mobility. Mechanical performance varies significantly between these two types, with isotactic polypropylene favored for structural applications and syndiotactic polypropylene preferred in flexible or elastic product designs.

Thermal and Chemical Resistance

Isotactic polypropylene exhibits higher crystallinity, resulting in superior thermal resistance with a melting point around 170degC and greater chemical stability against solvents and acids. Syndiotactic polypropylene, while having a lower melting point near 130-140degC, offers improved flexibility and impact resistance but reduced chemical resistance compared to its isotactic counterpart. The distinct stereoregularity in isotactic polypropylene enhances its robustness in high-temperature and aggressive chemical environments.

Crystallinity and Morphology

Isotactic polypropylene exhibits high crystallinity due to its regular, repeating methyl group arrangement along the polymer chain, resulting in a highly ordered, semicrystalline morphology. Syndiotactic polypropylene features alternating methyl group positions, which leads to a distinct crystalline structure with lower crystallinity and different lamellar thickness compared to isotactic polypropylene. These differences in crystallinity and morphology directly impact thermal properties, mechanical strength, and transparency of the respective polypropylene types.

Applications in Industry

Isotactic polypropylene exhibits high crystallinity and mechanical strength, making it ideal for packaging, automotive parts, and household goods. Syndiotactic polypropylene offers superior impact resistance and thermal stability, suited for specialty films, fibers, and electrical insulation. Both polymers find distinct industrial applications due to their differing stereoregular structures influencing material properties.

Environmental Impact and Recyclability

Isotactic polypropylene exhibits higher crystallinity and density, enhancing its mechanical strength but complicating recycling processes due to its rigid structure, whereas syndiotactic polypropylene offers increased flexibility and lower crystallinity, facilitating easier recycling and biodegradation. Environmental impact assessments reveal that syndiotactic polypropylene contributes to reduced carbon footprint and energy consumption during recycling compared to isotactic forms. Both types are recyclable, but syndiotactic polypropylene's molecular arrangement promotes more efficient chemical and mechanical recycling pathways, making it a preferable choice for sustainable polymer applications.

Cost and Availability

Isotactic polypropylene is generally more cost-effective and widely available due to its simpler production process and high demand in packaging and automotive industries. Syndiotactic polypropylene, being produced through more specialized catalysts, tends to have higher manufacturing costs and limited commercial availability. Market supply for isotactic variants dominates, making it the preferred choice for large-scale applications requiring economic efficiency.

Choosing the Right Polypropylene for Your Application

Isotactic polypropylene features a highly regular stereochemistry, resulting in greater crystallinity, strength, and chemical resistance, making it ideal for packaging, automotive parts, and household goods. Syndiotactic polypropylene, with its alternating stereochemistry, offers enhanced transparency, flexibility, and impact resistance, suited for applications like films, fibers, and medical devices. Selecting the right polypropylene depends on the required mechanical properties, thermal stability, and end-use performance criteria of your specific application.

Isotactic Polypropylene vs Syndiotactic Polypropylene Infographic

materialdif.com

materialdif.com