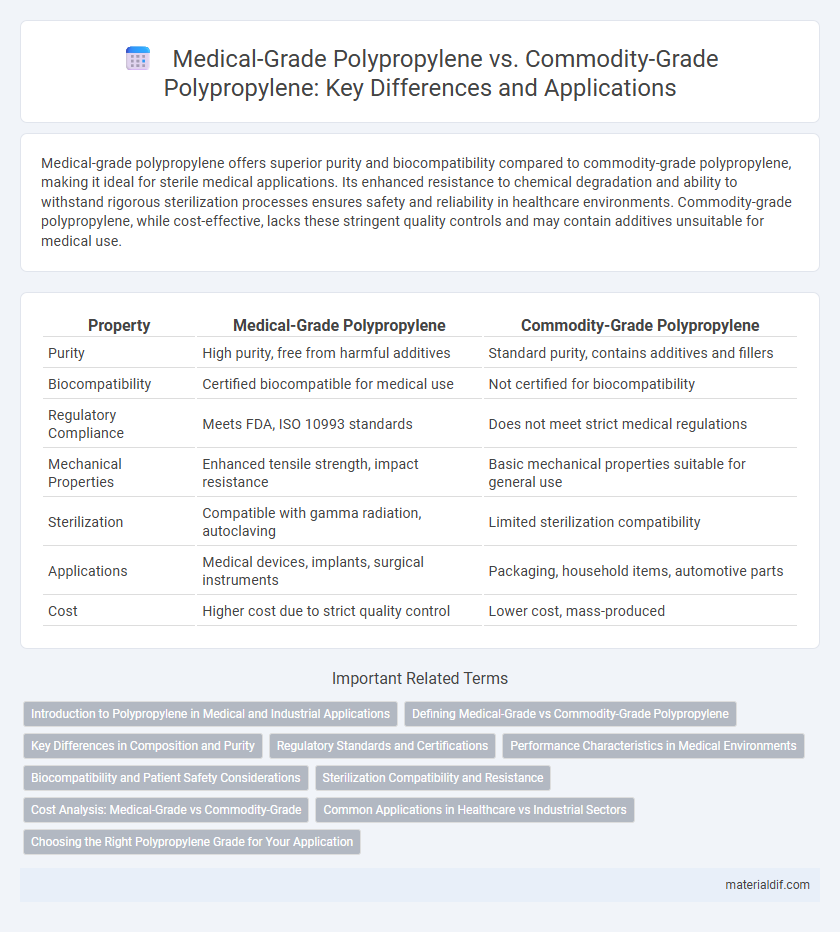

Medical-grade polypropylene offers superior purity and biocompatibility compared to commodity-grade polypropylene, making it ideal for sterile medical applications. Its enhanced resistance to chemical degradation and ability to withstand rigorous sterilization processes ensures safety and reliability in healthcare environments. Commodity-grade polypropylene, while cost-effective, lacks these stringent quality controls and may contain additives unsuitable for medical use.

Table of Comparison

| Property | Medical-Grade Polypropylene | Commodity-Grade Polypropylene |

|---|---|---|

| Purity | High purity, free from harmful additives | Standard purity, contains additives and fillers |

| Biocompatibility | Certified biocompatible for medical use | Not certified for biocompatibility |

| Regulatory Compliance | Meets FDA, ISO 10993 standards | Does not meet strict medical regulations |

| Mechanical Properties | Enhanced tensile strength, impact resistance | Basic mechanical properties suitable for general use |

| Sterilization | Compatible with gamma radiation, autoclaving | Limited sterilization compatibility |

| Applications | Medical devices, implants, surgical instruments | Packaging, household items, automotive parts |

| Cost | Higher cost due to strict quality control | Lower cost, mass-produced |

Introduction to Polypropylene in Medical and Industrial Applications

Medical-grade polypropylene is engineered with high purity and strict compliance to biocompatibility standards, making it ideal for surgical instruments, implantable devices, and pharmaceutical packaging. Commodity-grade polypropylene, while cost-effective and versatile, primarily serves non-critical industrial applications such as packaging, automotive parts, and consumer goods. The distinction lies in additives, processing controls, and certification processes that ensure medical-grade polypropylene meets stringent safety and performance criteria.

Defining Medical-Grade vs Commodity-Grade Polypropylene

Medical-grade polypropylene is specifically formulated and tested to meet stringent biocompatibility, sterilization, and purity standards required for medical applications, ensuring safety and compliance with ISO and FDA regulations. Commodity-grade polypropylene, on the other hand, is manufactured for general industrial use without rigorous testing for human contact, focusing on cost-effectiveness and broad application suitability. Key differences include the absence of contaminants, enhanced polymer stability, and certification in medical-grade variants compared to the broader, less controlled composition of commodity-grade polypropylene.

Key Differences in Composition and Purity

Medical-grade polypropylene is formulated with higher purity standards, containing fewer additives and contaminants compared to commodity-grade polypropylene, ensuring biocompatibility and sterility for medical applications. The composition of medical-grade polypropylene often includes specific stabilizers and processing aids that meet strict regulatory requirements, while commodity-grade variants prioritize cost-effectiveness and general-purpose use. Purity levels in medical-grade polypropylene result in enhanced resistance to leachables and extractables, crucial for patient safety and compliance with health regulations.

Regulatory Standards and Certifications

Medical-grade polypropylene complies with stringent regulatory standards such as FDA 21 CFR 177.1520 and USP Class VI certification, ensuring biocompatibility, sterilization compatibility, and chemical resistance required for medical applications. Commodity-grade polypropylene lacks these certifications and is primarily designed for general packaging and manufacturing, without the rigorous safety validations. The adherence to ISO 10993 biological evaluation standards further differentiates medical-grade polypropylene for use in critical healthcare environments.

Performance Characteristics in Medical Environments

Medical-grade polypropylene exhibits superior biocompatibility, chemical resistance, and sterilization tolerance compared to commodity-grade polypropylene, making it ideal for applications such as surgical instruments and medical packaging. Its enhanced purity and consistent molecular structure ensure minimal leachables and contaminants, critical for patient safety in medical environments. Commodity-grade polypropylene generally lacks these stringent performance characteristics, limiting its use in sensitive healthcare settings where reliability and compliance with regulatory standards are mandatory.

Biocompatibility and Patient Safety Considerations

Medical-grade polypropylene undergoes rigorous testing to ensure superior biocompatibility, making it suitable for implants, surgical instruments, and medical devices that require prolonged contact with biological tissues. Unlike commodity-grade polypropylene, which is designed primarily for general packaging and consumer products, medical-grade variants exhibit enhanced purity, reduced extractables, and compliance with stringent FDA and ISO standards for patient safety. These characteristics minimize the risk of adverse reactions, bacterial contamination, and chemical leaching, ensuring reliable performance in critical healthcare applications.

Sterilization Compatibility and Resistance

Medical-grade polypropylene exhibits superior sterilization compatibility, enduring autoclaving, gamma irradiation, and ethylene oxide sterilization without degradation, unlike commodity-grade polypropylene which often deforms or loses mechanical integrity under such conditions. The enhanced resistance of medical-grade polypropylene to chemical and thermal stress ensures its safety and durability in sterile environments, critical for medical devices and packaging. Commodity-grade polypropylene lacks these stringent performance specifications, limiting its use in medical applications where sterilization and resistance are mandatory.

Cost Analysis: Medical-Grade vs Commodity-Grade

Medical-grade polypropylene commands higher prices due to stringent purity standards, biocompatibility certifications, and enhanced sterilization resistance essential for healthcare applications. Commodity-grade polypropylene offers a cost-effective alternative with lower processing requirements but lacks the rigorous quality controls needed for medical use. The cost differential reflects the additional testing, regulatory compliance, and material consistency required to meet medical industry specifications.

Common Applications in Healthcare vs Industrial Sectors

Medical-grade polypropylene is specifically engineered for biocompatibility and sterilization, making it ideal for surgical instruments, medical packaging, and disposable syringes in healthcare. Commodity-grade polypropylene, while offering affordability and versatility, is predominantly used in industrial sectors for automotive parts, consumer goods, and packaging materials. The strict regulatory requirements of medical-grade polypropylene distinguish it by ensuring safety and performance in critical healthcare applications compared to the broader, less regulated industrial uses of commodity-grade polypropylene.

Choosing the Right Polypropylene Grade for Your Application

Medical-grade polypropylene features enhanced purity, biocompatibility, and regulatory approvals such as USP Class VI and ISO 10993 certifications, making it ideal for applications like surgical instruments and pharmaceutical packaging. Commodity-grade polypropylene offers cost-effective solutions with general-purpose properties suited for everyday items like packaging, textiles, and automotive parts. Selecting the appropriate grade depends on application requirements for safety, chemical resistance, mechanical strength, and compliance standards.

Medical-Grade Polypropylene vs Commodity-Grade Polypropylene Infographic

materialdif.com

materialdif.com