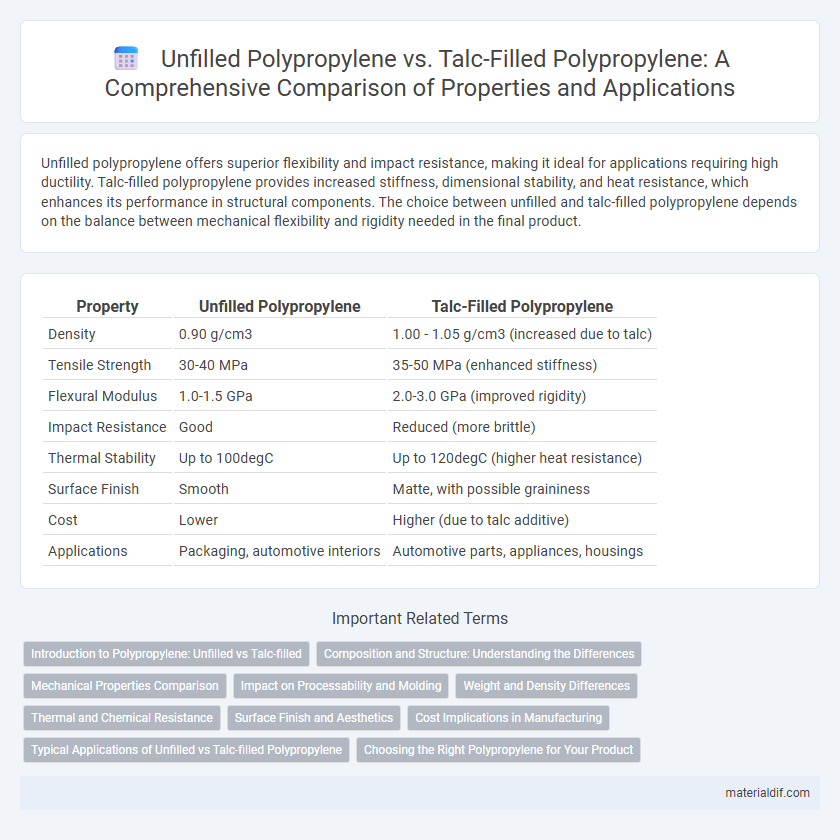

Unfilled polypropylene offers superior flexibility and impact resistance, making it ideal for applications requiring high ductility. Talc-filled polypropylene provides increased stiffness, dimensional stability, and heat resistance, which enhances its performance in structural components. The choice between unfilled and talc-filled polypropylene depends on the balance between mechanical flexibility and rigidity needed in the final product.

Table of Comparison

| Property | Unfilled Polypropylene | Talc-Filled Polypropylene |

|---|---|---|

| Density | 0.90 g/cm3 | 1.00 - 1.05 g/cm3 (increased due to talc) |

| Tensile Strength | 30-40 MPa | 35-50 MPa (enhanced stiffness) |

| Flexural Modulus | 1.0-1.5 GPa | 2.0-3.0 GPa (improved rigidity) |

| Impact Resistance | Good | Reduced (more brittle) |

| Thermal Stability | Up to 100degC | Up to 120degC (higher heat resistance) |

| Surface Finish | Smooth | Matte, with possible graininess |

| Cost | Lower | Higher (due to talc additive) |

| Applications | Packaging, automotive interiors | Automotive parts, appliances, housings |

Introduction to Polypropylene: Unfilled vs Talc-filled

Unfilled polypropylene exhibits high flexibility, excellent chemical resistance, and low density, making it ideal for lightweight applications. Talc-filled polypropylene enhances stiffness, heat resistance, and dimensional stability by incorporating talc as a mineral filler, improving mechanical properties for automotive and industrial uses. The choice between unfilled and talc-filled polypropylene depends on performance requirements such as impact strength, thermal stability, and cost-efficiency.

Composition and Structure: Understanding the Differences

Unfilled polypropylene consists solely of the polymer matrix, retaining high impact resistance and flexibility, while talc-filled polypropylene incorporates fine talc particles distributed throughout the polymer, enhancing stiffness and thermal stability. The addition of talc alters the semicrystalline structure by acting as a nucleating agent, which promotes the formation of smaller, more uniform spherulites, resulting in improved mechanical strength and dimensional stability. Understanding these compositional and structural differences is essential for selecting the appropriate polypropylene type for applications requiring specific performance characteristics such as rigidity, heat resistance, or impact tolerance.

Mechanical Properties Comparison

Unfilled polypropylene exhibits greater elongation at break and impact resistance, making it suitable for applications requiring flexibility and toughness. Talc-filled polypropylene offers enhanced stiffness and dimensional stability, with increased tensile strength but reduced impact resistance due to the rigid filler particles. The choice between unfilled and talc-filled polypropylene depends on balancing required mechanical properties such as rigidity versus ductility in end-use applications.

Impact on Processability and Molding

Unfilled polypropylene offers superior melt flow and ease of processing, making it ideal for complex molding applications requiring high precision. Talc-filled polypropylene improves stiffness and thermal resistance but increases melt viscosity, which can lead to higher injection pressures and longer cycle times. Selecting the appropriate formulation depends on balancing processability with the desired mechanical properties for specific molding requirements.

Weight and Density Differences

Unfilled polypropylene exhibits a lower density of approximately 0.90 g/cm3, making it lighter compared to talc-filled polypropylene, which typically ranges from 1.0 to 1.2 g/cm3 due to the added mineral filler. The increased density in talc-filled polypropylene results in higher weight per volume, enhancing rigidity and dimensional stability but compromising lightweight advantages. Weight-sensitive applications favor unfilled polypropylene for reduced mass, while talc-filled variants balance strength and moderate weight increases for performance-demanding uses.

Thermal and Chemical Resistance

Unfilled polypropylene exhibits superior chemical resistance against acids, bases, and solvents, making it ideal for applications requiring high corrosion resistance. Talc-filled polypropylene offers enhanced thermal stability, with a higher heat deflection temperature, improving performance in elevated temperature environments. The inclusion of talc also reduces thermal expansion, providing dimensional stability without significantly compromising chemical resistance.

Surface Finish and Aesthetics

Unfilled polypropylene offers a smoother surface finish with a natural, glossy appearance that enhances aesthetics for applications requiring clarity and softness. Talc-filled polypropylene exhibits improved surface texture uniformity and matte finish, which reduces glare and enhances paint adhesion for decorative uses. The addition of talc also increases stiffness but may slightly reduce the surface smoothness compared to unfilled polypropylene.

Cost Implications in Manufacturing

Unfilled polypropylene generally offers lower raw material costs and simplified processing, making it economically advantageous for high-volume production with minimal mechanical property requirements. Talc-filled polypropylene increases material expenses due to the additive cost, but enhances stiffness and dimensional stability, potentially reducing downstream manufacturing costs such as tool wear and cycle time. Manufacturers must balance the initial investment in talc additives against long-term savings in production efficiency and product performance.

Typical Applications of Unfilled vs Talc-filled Polypropylene

Unfilled polypropylene is widely used in applications requiring high chemical resistance and flexibility, such as in food packaging, medical containers, and automotive interior parts. Talc-filled polypropylene offers enhanced stiffness and dimensional stability, making it ideal for automotive components, appliance housings, and industrial equipment where improved heat resistance and durability are critical. The choice between unfilled and talc-filled grades depends on the specific mechanical and thermal requirements of the end-use application.

Choosing the Right Polypropylene for Your Product

Unfilled polypropylene offers excellent flexibility, chemical resistance, and ease of processing, ideal for applications requiring lightweight and impact resilience. Talc-filled polypropylene provides enhanced stiffness, dimensional stability, and thermal resistance, making it suitable for automotive parts, appliances, and structural components. Selecting the right polypropylene depends on balancing the need for mechanical strength and rigidity versus flexibility and surface finish in your product design.

Unfilled Polypropylene vs Talc-filled Polypropylene Infographic

materialdif.com

materialdif.com