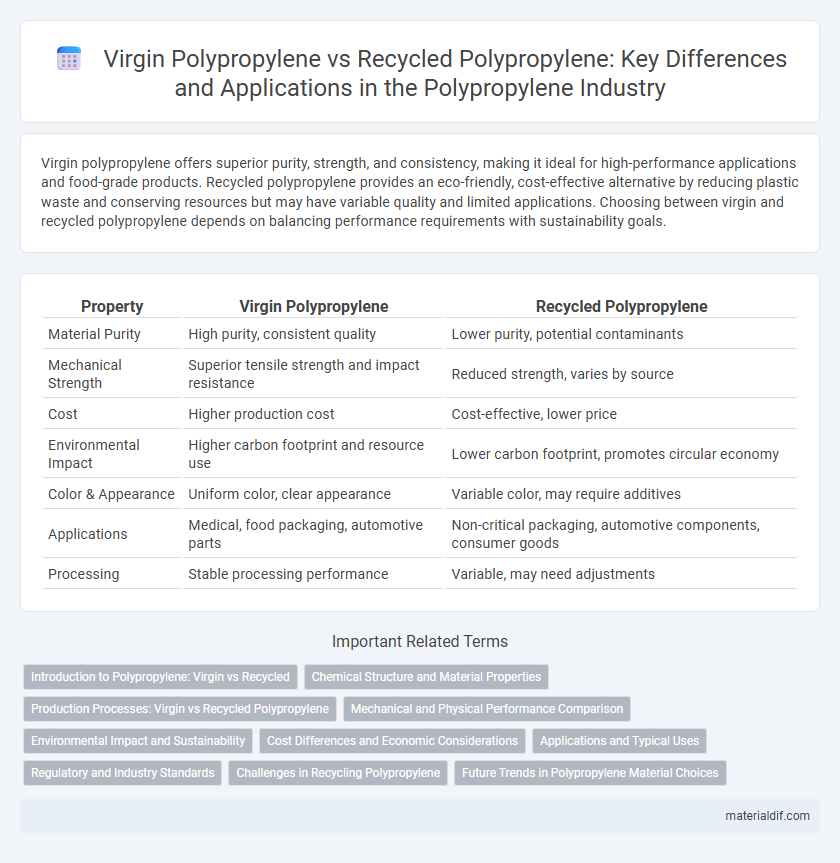

Virgin polypropylene offers superior purity, strength, and consistency, making it ideal for high-performance applications and food-grade products. Recycled polypropylene provides an eco-friendly, cost-effective alternative by reducing plastic waste and conserving resources but may have variable quality and limited applications. Choosing between virgin and recycled polypropylene depends on balancing performance requirements with sustainability goals.

Table of Comparison

| Property | Virgin Polypropylene | Recycled Polypropylene |

|---|---|---|

| Material Purity | High purity, consistent quality | Lower purity, potential contaminants |

| Mechanical Strength | Superior tensile strength and impact resistance | Reduced strength, varies by source |

| Cost | Higher production cost | Cost-effective, lower price |

| Environmental Impact | Higher carbon footprint and resource use | Lower carbon footprint, promotes circular economy |

| Color & Appearance | Uniform color, clear appearance | Variable color, may require additives |

| Applications | Medical, food packaging, automotive parts | Non-critical packaging, automotive components, consumer goods |

| Processing | Stable processing performance | Variable, may need adjustments |

Introduction to Polypropylene: Virgin vs Recycled

Virgin polypropylene offers superior purity, higher tensile strength, and consistent molecular weight, making it ideal for high-performance applications. Recycled polypropylene, derived from post-consumer or industrial waste, provides cost-effective and environmentally sustainable alternatives but may exhibit slight variations in color, strength, and contamination levels. Understanding the differences in mechanical properties and lifecycle impact between virgin and recycled polypropylene is essential for optimizing material selection in manufacturing and product development.

Chemical Structure and Material Properties

Virgin polypropylene features a pristine, uniform chemical structure with long, unbroken polymer chains that provide superior tensile strength, clarity, and resistance to environmental stress cracking. Recycled polypropylene often contains shorter polymer chains and contaminants from processing, leading to reduced mechanical properties, diminished impact resistance, and potential variability in thermal stability. The degradation of molecular weight and introduction of impurities in recycled polypropylene alter its crystallinity and reduce its overall material performance compared to virgin polypropylene.

Production Processes: Virgin vs Recycled Polypropylene

Virgin polypropylene is produced directly from petrochemical feedstocks through polymerization processes such as Ziegler-Natta or metallocene catalysis, resulting in high-purity polymer pellets with consistent mechanical properties. Recycled polypropylene involves melting and reprocessing post-consumer or post-industrial waste, which often undergoes sorting, washing, and pelletizing stages but may suffer from property degradation due to thermal and oxidative stress. The production process for recycled polypropylene emphasizes sustainability and resource efficiency but requires advanced purification and additive technologies to maintain performance comparable to virgin materials.

Mechanical and Physical Performance Comparison

Virgin polypropylene exhibits superior mechanical properties such as higher tensile strength and impact resistance compared to recycled polypropylene, which often shows reduced performance due to polymer degradation and contamination. Recycled polypropylene typically has altered crystallinity and reduced molecular weight, resulting in lower stiffness and diminished thermal stability. Despite these drawbacks, recycled polypropylene remains valuable for applications where marginally lower mechanical and physical performance is acceptable to promote sustainability.

Environmental Impact and Sustainability

Virgin polypropylene production consumes more energy and generates higher greenhouse gas emissions compared to recycled polypropylene, increasing its environmental footprint. Recycled polypropylene significantly reduces landfill waste and conserves fossil fuel resources by reusing existing plastic materials. Sustainable practices involving recycled polypropylene support circular economy goals and mitigate pollution associated with plastic manufacturing.

Cost Differences and Economic Considerations

Virgin polypropylene typically incurs higher production costs due to raw material extraction and energy-intensive processes, resulting in increased market prices compared to recycled polypropylene. Recycled polypropylene offers significant cost savings by utilizing post-consumer or post-industrial waste, reducing dependency on petroleum-based feedstocks and minimizing environmental impact. Economic considerations favor recycled polypropylene in manufacturing sectors aiming for lower material expenses and sustainable supply chains without compromising performance standards.

Applications and Typical Uses

Virgin polypropylene offers superior strength, clarity, and chemical resistance, making it ideal for high-performance applications such as medical devices, food packaging, and automotive components. Recycled polypropylene, while slightly lower in mechanical properties, is widely used in non-critical packaging, household goods, and construction materials where environmental sustainability is prioritized. Both materials serve distinct market needs, balancing performance requirements and ecological impact across various industries.

Regulatory and Industry Standards

Virgin polypropylene complies with stringent regulatory standards such as FDA 21 CFR 177.1520 for food contact applications, ensuring high purity and consistent performance. Recycled polypropylene must meet additional industry guidelines, including ISO 14021 environmental claims and compliance with the EU's REACH regulations to address contamination and chemical safety. Both materials require adherence to ASTM D4101 for mechanical properties, but recycled grades often undergo rigorous testing to ensure safety and quality in line with sustainability mandates.

Challenges in Recycling Polypropylene

Recycling polypropylene presents significant challenges due to contamination, degradation of polymer properties, and the separation of mixed plastics in waste streams. Virgin polypropylene maintains consistent mechanical strength and purity, while recycled polypropylene often suffers from reduced tensile strength and discoloration, limiting its applications. Advanced sorting technologies and chemical recycling methods are critical to improving the quality and usability of recycled polypropylene materials.

Future Trends in Polypropylene Material Choices

Future trends in polypropylene material choices emphasize increased demand for recycled polypropylene due to rising environmental regulations and consumer preference for sustainable products. Innovations in chemical recycling technologies enhance the quality and usability of recycled polypropylene, narrowing the performance gap with virgin polypropylene. Market analysis predicts a significant growth in circular polypropylene supply chains, driven by advances in sorting, processing, and sustainable product design.

Virgin Polypropylene vs Recycled Polypropylene Infographic

materialdif.com

materialdif.com