Polypropylene UV stabilized offers enhanced resistance to sunlight degradation, preventing discoloration, brittleness, and loss of mechanical properties over time. In contrast, polypropylene non-stabilized degrades quickly when exposed to UV radiation, resulting in reduced durability and performance in outdoor applications. Selecting UV stabilized polypropylene ensures longer lifespan and reliability for products subjected to prolonged sun exposure.

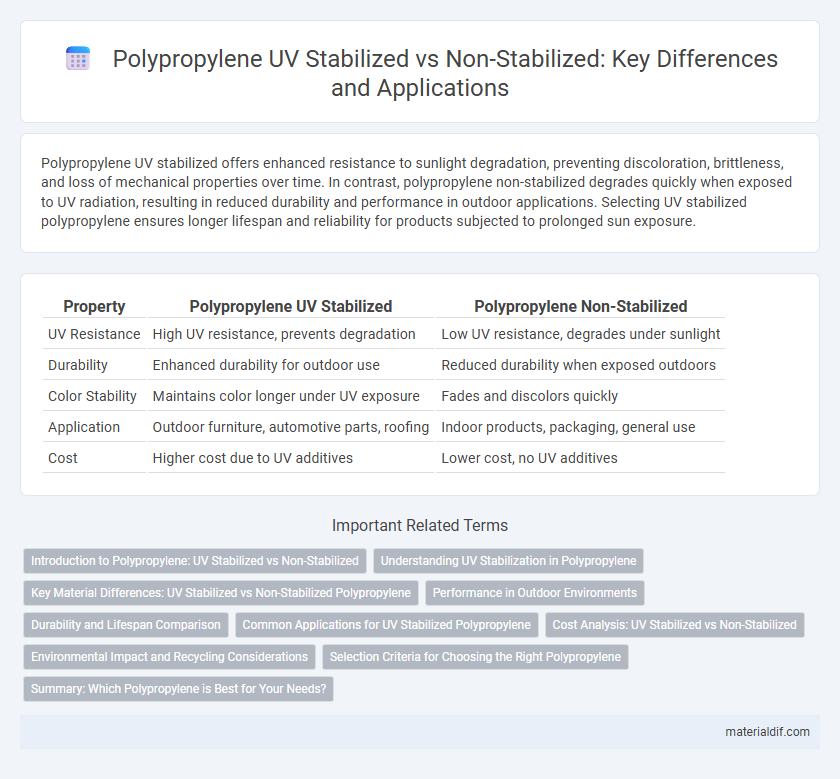

Table of Comparison

| Property | Polypropylene UV Stabilized | Polypropylene Non-Stabilized |

|---|---|---|

| UV Resistance | High UV resistance, prevents degradation | Low UV resistance, degrades under sunlight |

| Durability | Enhanced durability for outdoor use | Reduced durability when exposed outdoors |

| Color Stability | Maintains color longer under UV exposure | Fades and discolors quickly |

| Application | Outdoor furniture, automotive parts, roofing | Indoor products, packaging, general use |

| Cost | Higher cost due to UV additives | Lower cost, no UV additives |

Introduction to Polypropylene: UV Stabilized vs Non-Stabilized

Polypropylene UV stabilized incorporates additives designed to resist degradation from ultraviolet radiation, enhancing its durability and lifespan in outdoor applications. In contrast, non-stabilized polypropylene lacks these protective agents, making it more susceptible to brittleness, color fading, and structural weakening when exposed to sunlight. Understanding the differences between UV stabilized and non-stabilized polypropylene is crucial for selecting the right material for products exposed to environmental elements.

Understanding UV Stabilization in Polypropylene

Polypropylene UV stabilized contains additives that absorb or block harmful ultraviolet rays, significantly enhancing the polymer's resistance to degradation caused by prolonged sun exposure. In contrast, polypropylene non-stabilized lacks these protective additives, making it more susceptible to brittleness, discoloration, and loss of mechanical properties when exposed to UV radiation. Understanding UV stabilization in polypropylene is crucial for applications requiring long-term outdoor durability, such as automotive parts, roofing materials, and outdoor furniture.

Key Material Differences: UV Stabilized vs Non-Stabilized Polypropylene

UV stabilized polypropylene contains additives that protect the polymer chains from degradation caused by ultraviolet radiation, significantly enhancing its durability and lifespan in outdoor applications. Non-stabilized polypropylene lacks these additives, making it more susceptible to embrittlement, color fading, and loss of mechanical properties when exposed to prolonged sunlight. This key difference affects the material's performance, with UV stabilized polypropylene being preferred for outdoor use, while non-stabilized variants are suitable for indoor or short-term exposure environments.

Performance in Outdoor Environments

Polypropylene UV stabilized contains additives that significantly enhance its resistance to sunlight, preventing degradation through UV radiation and extending material lifespan in outdoor applications. In contrast, polypropylene non-stabilized experiences rapid deterioration, including discoloration, brittleness, and loss of mechanical integrity when exposed to direct sunlight. This makes UV stabilized polypropylene essential for durable outdoor products such as piping, automotive parts, and garden furniture where long-term performance is critical.

Durability and Lifespan Comparison

Polypropylene UV stabilized offers enhanced durability and extended lifespan by resisting degradation from ultraviolet light exposure, making it ideal for outdoor applications. Non-stabilized polypropylene is prone to UV-induced brittleness, discoloration, and reduced mechanical strength, limiting its functional lifespan. UV stabilization additives such as HALS (Hindered Amine Light Stabilizers) significantly improve polypropylene's resistance to photodegradation, ensuring structural integrity over time.

Common Applications for UV Stabilized Polypropylene

UV stabilized polypropylene is extensively used in outdoor applications such as automotive parts, garden furniture, and roofing membranes due to its enhanced resistance to ultraviolet radiation and weathering. This stabilization prevents degradation and prolongs material lifespan when exposed to sunlight, making it ideal for agricultural films, outdoor piping, and electrical enclosures. Non-stabilized polypropylene is generally unsuitable for prolonged outdoor exposure as it tends to become brittle and discolored under UV light.

Cost Analysis: UV Stabilized vs Non-Stabilized

Polypropylene UV stabilized materials generally incur higher upfront costs due to the incorporation of UV inhibitors that enhance weather resistance and prolong product lifespan, reducing long-term maintenance and replacement expenses. Non-stabilized polypropylene offers a lower initial cost but is more susceptible to degradation from UV exposure, leading to frequent replacements and higher cumulative expenses over time. Cost analysis reveals that investing in UV stabilized polypropylene yields better value in outdoor applications by minimizing durability-related costs despite the higher initial price.

Environmental Impact and Recycling Considerations

Polypropylene UV stabilized contains additives that enhance resistance to ultraviolet light, reducing degradation and extending the material's lifespan in outdoor applications, which can lower environmental waste over time. Non-stabilized polypropylene degrades faster under UV exposure, leading to more frequent replacement and increased plastic waste generation. Recycling processes for both types are similar, but UV stabilizers may affect polymer purity, potentially complicating recycling streams and requiring specialized treatment to maintain material quality.

Selection Criteria for Choosing the Right Polypropylene

UV stabilized polypropylene incorporates additives that protect the polymer from degradation caused by prolonged exposure to ultraviolet light, enhancing durability in outdoor applications. Non-stabilized polypropylene lacks these additives, making it suitable primarily for indoor or low UV exposure environments where cost-effectiveness is prioritized. Selection criteria should consider environmental exposure, expected lifespan, and mechanical performance to determine the appropriate polypropylene grade for specific applications.

Summary: Which Polypropylene is Best for Your Needs?

Polypropylene UV stabilized offers enhanced durability and resistance to degradation caused by prolonged exposure to sunlight, making it ideal for outdoor applications such as automotive parts, packaging, and outdoor furniture. Non-stabilized polypropylene, while cost-effective and suitable for indoor or temporary use, lacks the additives that prevent UV damage, resulting in brittleness and color fading over time. Choosing between the two depends on the environmental exposure and lifespan requirements of the product, with UV stabilized polypropylene providing superior long-term performance in UV-intense settings.

Polypropylene UV Stabilized vs Polypropylene Non-Stabilized Infographic

materialdif.com

materialdif.com