Heat stabilized polypropylene is engineered to withstand high temperatures without degrading, making it ideal for applications involving prolonged heat exposure. UV stabilized polypropylene contains additives that protect the material from ultraviolet radiation, preventing discoloration and brittleness when used outdoors. Choosing between the two depends on whether thermal resistance or UV protection is more critical for the intended application.

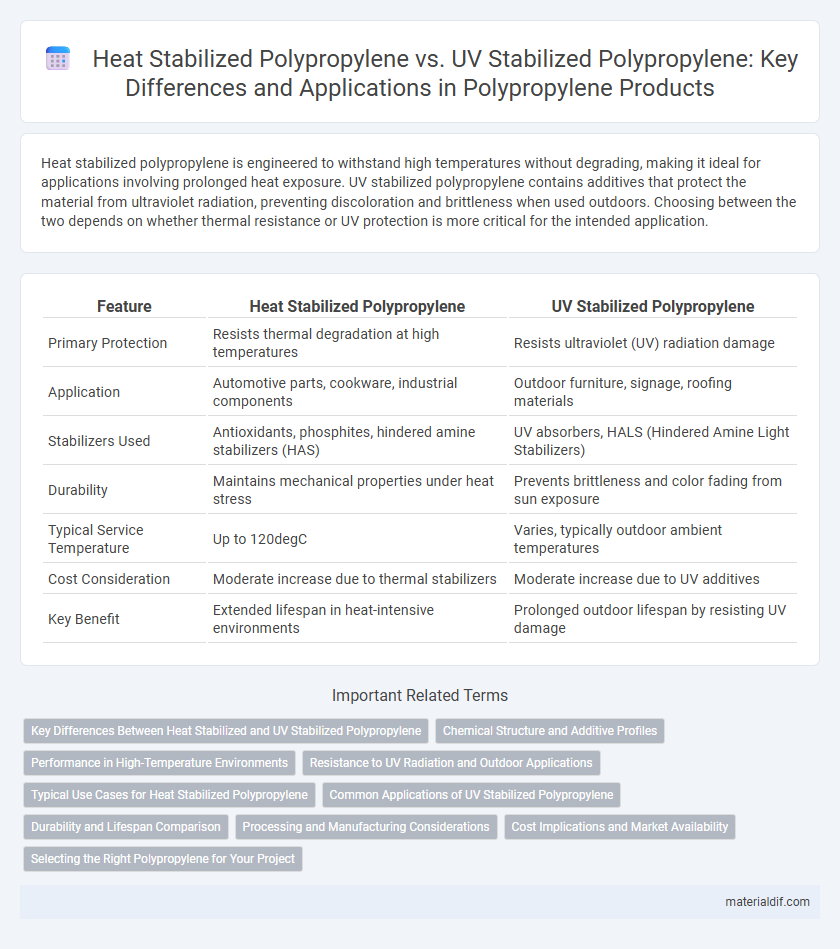

Table of Comparison

| Feature | Heat Stabilized Polypropylene | UV Stabilized Polypropylene |

|---|---|---|

| Primary Protection | Resists thermal degradation at high temperatures | Resists ultraviolet (UV) radiation damage |

| Application | Automotive parts, cookware, industrial components | Outdoor furniture, signage, roofing materials |

| Stabilizers Used | Antioxidants, phosphites, hindered amine stabilizers (HAS) | UV absorbers, HALS (Hindered Amine Light Stabilizers) |

| Durability | Maintains mechanical properties under heat stress | Prevents brittleness and color fading from sun exposure |

| Typical Service Temperature | Up to 120degC | Varies, typically outdoor ambient temperatures |

| Cost Consideration | Moderate increase due to thermal stabilizers | Moderate increase due to UV additives |

| Key Benefit | Extended lifespan in heat-intensive environments | Prolonged outdoor lifespan by resisting UV damage |

Key Differences Between Heat Stabilized and UV Stabilized Polypropylene

Heat stabilized polypropylene contains additives that enhance its resistance to thermal degradation, maintaining structural integrity at elevated temperatures up to 150degC. UV stabilized polypropylene incorporates UV absorbers or hindered amine light stabilizers (HALS) to prevent polymer chain breakdown caused by ultraviolet radiation exposure, extending outdoor durability. The key difference lies in their stabilization focus: heat stabilized polypropylene targets thermal resistance for high-temperature applications, whereas UV stabilized polypropylene ensures longevity under prolonged sunlight exposure.

Chemical Structure and Additive Profiles

Heat stabilized polypropylene contains antioxidants and thermal stabilizers that protect the polymer chains by inhibiting thermal degradation and chain scission, maintaining its mechanical properties at elevated temperatures. UV stabilized polypropylene incorporates UV absorbers and hindered amine light stabilizers (HALS) that prevent photodegradation by absorbing harmful ultraviolet radiation and neutralizing free radicals generated by UV exposure. The distinct additive profiles in these types influence the chemical structure's resistance mechanisms, with heat stabilization targeting thermal radical stabilization and UV stabilization focusing on preventing polymer chain breakdown from UV-induced reactions.

Performance in High-Temperature Environments

Heat stabilized polypropylene exhibits superior resistance to thermal degradation, maintaining structural integrity and mechanical properties in high-temperature environments up to 120degC. UV stabilized polypropylene, while primarily designed to resist photodegradation from ultraviolet radiation, offers limited protection against prolonged heat exposure and may suffer from embrittlement or discoloration at elevated temperatures. Heat stabilized variants are ideal for applications requiring consistent performance under sustained thermal stress, such as automotive engine components and industrial machinery parts.

Resistance to UV Radiation and Outdoor Applications

Heat stabilized polypropylene incorporates antioxidants and heat stabilizers to enhance thermal resistance, making it suitable for applications involving elevated temperatures. UV stabilized polypropylene contains UV absorbers and hindered amine light stabilizers (HALS), significantly improving resistance to ultraviolet radiation and preventing polymer degradation under prolonged sun exposure. For outdoor applications, UV stabilized polypropylene is preferred due to its superior durability against UV-induced brittleness and color fading, whereas heat stabilized polypropylene primarily protects against thermal oxidation during processing or short-term heat exposure.

Typical Use Cases for Heat Stabilized Polypropylene

Heat stabilized polypropylene is primarily used in applications requiring resistance to thermal degradation, such as automotive components, electrical housings, and cookware. It maintains mechanical properties and dimensional stability in high-temperature environments, making it ideal for appliances and industrial parts exposed to heat. Unlike UV stabilized polypropylene, which protects against sunlight and outdoor weathering, heat stabilized variants focus on performance in elevated temperature conditions.

Common Applications of UV Stabilized Polypropylene

UV stabilized polypropylene is commonly used in outdoor applications such as automotive parts, garden furniture, and roofing membranes where resistance to sunlight and weathering is critical. Its enhanced durability against ultraviolet radiation prevents degradation and extends the lifespan of products exposed to harsh environmental conditions. This stabilization makes UV stabilized polypropylene ideal for solar panel components and agricultural films that require long-term exposure to UV light.

Durability and Lifespan Comparison

Heat stabilized polypropylene offers enhanced resistance to thermal degradation, extending its lifespan in high-temperature environments up to 150degC. UV stabilized polypropylene incorporates additives like hindered amine light stabilizers (HALS) to prevent polymer chain breakdown caused by ultraviolet radiation, thereby improving outdoor durability. Comparing durability, UV stabilized polypropylene excels in outdoor applications with prolonged sun exposure, while heat stabilized polypropylene is preferable for high-heat industrial settings.

Processing and Manufacturing Considerations

Heat stabilized polypropylene requires precise thermal management during processing to prevent degradation and maintain material integrity, often necessitating controlled cooling rates and specialized equipment. UV stabilized polypropylene incorporates additives that necessitate adjustments in melt temperature and shear conditions to ensure uniform dispersion and avoid compromising UV resistance. Manufacturers must balance these factors to optimize production efficiency and product performance while reducing the risk of defects such as discoloration or brittleness.

Cost Implications and Market Availability

Heat stabilized polypropylene typically incurs lower production costs compared to UV stabilized variants due to simpler additive formulations and less rigorous testing requirements. UV stabilized polypropylene demands higher investment in specialized additives to resist degradation from sunlight exposure, making it more expensive but essential for outdoor applications. Market availability of heat stabilized polypropylene is broader, catering to general industrial needs, whereas UV stabilized polypropylene is more niche, primarily supplied for outdoor and automotive sectors with higher performance criteria.

Selecting the Right Polypropylene for Your Project

Heat stabilized polypropylene is engineered to withstand elevated temperatures without degradation, making it ideal for applications such as automotive components and electrical housings exposed to thermal stress. UV stabilized polypropylene incorporates additives that protect against ultraviolet radiation, preventing discoloration and brittleness in outdoor environments like garden furniture and piping. Selecting the right polypropylene depends on the operating environment: prioritize heat stabilization for high-temperature conditions and UV stabilization for prolonged sun exposure to ensure material longevity and performance.

Heat Stabilized Polypropylene vs UV Stabilized Polypropylene Infographic

materialdif.com

materialdif.com