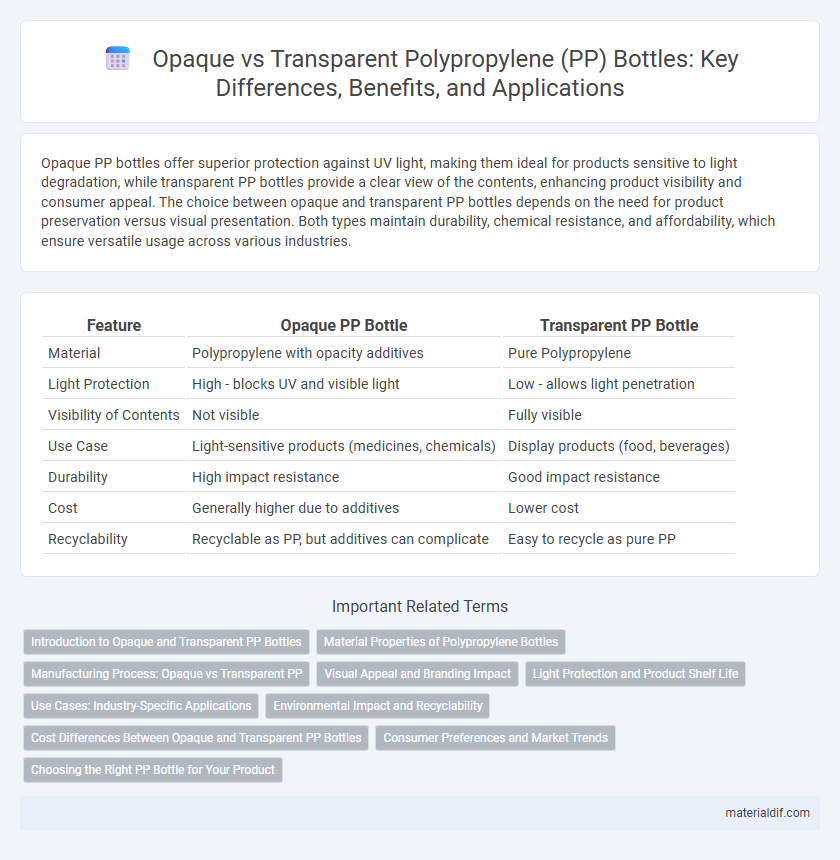

Opaque PP bottles offer superior protection against UV light, making them ideal for products sensitive to light degradation, while transparent PP bottles provide a clear view of the contents, enhancing product visibility and consumer appeal. The choice between opaque and transparent PP bottles depends on the need for product preservation versus visual presentation. Both types maintain durability, chemical resistance, and affordability, which ensure versatile usage across various industries.

Table of Comparison

| Feature | Opaque PP Bottle | Transparent PP Bottle |

|---|---|---|

| Material | Polypropylene with opacity additives | Pure Polypropylene |

| Light Protection | High - blocks UV and visible light | Low - allows light penetration |

| Visibility of Contents | Not visible | Fully visible |

| Use Case | Light-sensitive products (medicines, chemicals) | Display products (food, beverages) |

| Durability | High impact resistance | Good impact resistance |

| Cost | Generally higher due to additives | Lower cost |

| Recyclability | Recyclable as PP, but additives can complicate | Easy to recycle as pure PP |

Introduction to Opaque and Transparent PP Bottles

Opaque polypropylene (PP) bottles are designed with additives or fillers that block light, providing superior UV protection and preserving the product inside from photo-degradation. Transparent PP bottles offer clarity and visibility, making them ideal for showcasing the product, while maintaining chemical resistance and durability typical of polypropylene. Both types are widely used in packaging applications, with opaque bottles favored for sensitive contents and transparent bottles chosen for consumer appeal.

Material Properties of Polypropylene Bottles

Opaque polypropylene (PP) bottles offer enhanced UV protection and superior barrier properties compared to transparent PP bottles, making them ideal for sensitive product packaging. Transparent PP bottles provide excellent clarity and chemical resistance but have reduced light-blocking capabilities, which may affect the shelf life of light-sensitive contents. Both types exhibit high impact resistance, low moisture absorption, and thermal stability inherent to polypropylene material.

Manufacturing Process: Opaque vs Transparent PP

Opaque polypropylene (PP) bottles are manufactured using additives like titanium dioxide to scatter light, resulting in a non-transparent appearance, whereas transparent PP bottles rely on highly purified polymer resins with minimal additives to maintain clarity. The extrusion and injection molding parameters differ, with opaque PP requiring precise mixing to evenly distribute opacifying agents, while transparent PP demands stringent processing to avoid haze and maintain optical transparency. These manufacturing variations impact the thermal stability and mechanical properties, with opaque PP generally offering greater UV resistance and durability compared to transparent PP.

Visual Appeal and Branding Impact

Opaque polypropylene (PP) bottles offer enhanced visual appeal by providing a solid, consistent color that conceals contents and protects products from UV light, boosting brand perception in premium or sensitive product lines. Transparent PP bottles showcase the product inside, appealing to consumers who value product visibility and freshness, strengthening trust and authenticity in branding. Choosing between opaque and transparent PP bottles depends on the desired brand message, product protection needs, and target consumer preferences.

Light Protection and Product Shelf Life

Opaque polypropylene (PP) bottles provide superior light protection by blocking UV and visible light, preventing photodegradation of light-sensitive products and thereby extending their shelf life. Transparent PP bottles allow light transmission, which can accelerate oxidation and reduce the stability of contents prone to light exposure. Manufacturers often choose opaque PP bottles for products requiring enhanced preservation, such as pharmaceuticals, chemicals, and certain food items, to maintain efficacy and freshness over time.

Use Cases: Industry-Specific Applications

Opaque PP bottles are preferred in the pharmaceutical and chemical industries due to their ability to protect light-sensitive contents from UV exposure, ensuring product stability and longevity. Transparent PP bottles are widely used in the food and beverage sector, enabling easy visual inspection of contents for quality control and consumer appeal. Packaging manufacturers tailor the choice between opaque and transparent polypropylene based on application requirements such as UV protection, product visibility, and regulatory standards.

Environmental Impact and Recyclability

Opaque polypropylene (PP) bottles typically contain additives like titanium dioxide to enhance opacity, which can complicate recycling processes by requiring additional separation steps. Transparent PP bottles are more straightforward to recycle due to their pure resin content and absence of colorants that interfere with material recovery. From an environmental impact perspective, transparent PP bottles promote higher recycling rates and reduce contamination in recycling streams compared to opaque variants, supporting circular economy goals.

Cost Differences Between Opaque and Transparent PP Bottles

Opaque PP bottles typically cost more than transparent PP bottles due to the addition of pigments and fillers that enhance opacity and UV protection. The manufacturing process for opaque bottles involves extra steps and materials that increase production expenses, making them less economical for large-scale applications. Transparent PP bottles are favored for cost-sensitive markets because their simpler production requires fewer additives, resulting in lower material and processing costs.

Consumer Preferences and Market Trends

Opaque PP bottles offer superior UV protection and concealment, appealing to consumers seeking product integrity and privacy, especially in personal care and chemical packaging. Transparent PP bottles provide clear visibility of contents, favoring markets where product appearance and volume confirmation influence purchasing decisions, such as food and beverage sectors. Market trends indicate a growing preference for sustainable, recyclable materials, with transparent PP bottles gaining traction due to their recyclability and consumer demand for transparency in product quality.

Choosing the Right PP Bottle for Your Product

Opaque polypropylene (PP) bottles offer superior protection against UV light and chemical degradation, making them ideal for sensitive products like pharmaceuticals and cosmetics. Transparent PP bottles provide excellent product visibility, enabling consumers to easily see contents, which benefits food and beverage packaging or promotional items. Selecting the right PP bottle depends on balancing product stability requirements with the importance of visual presentation and consumer appeal.

Opaque PP Bottle vs Transparent PP Bottle Infographic

materialdif.com

materialdif.com