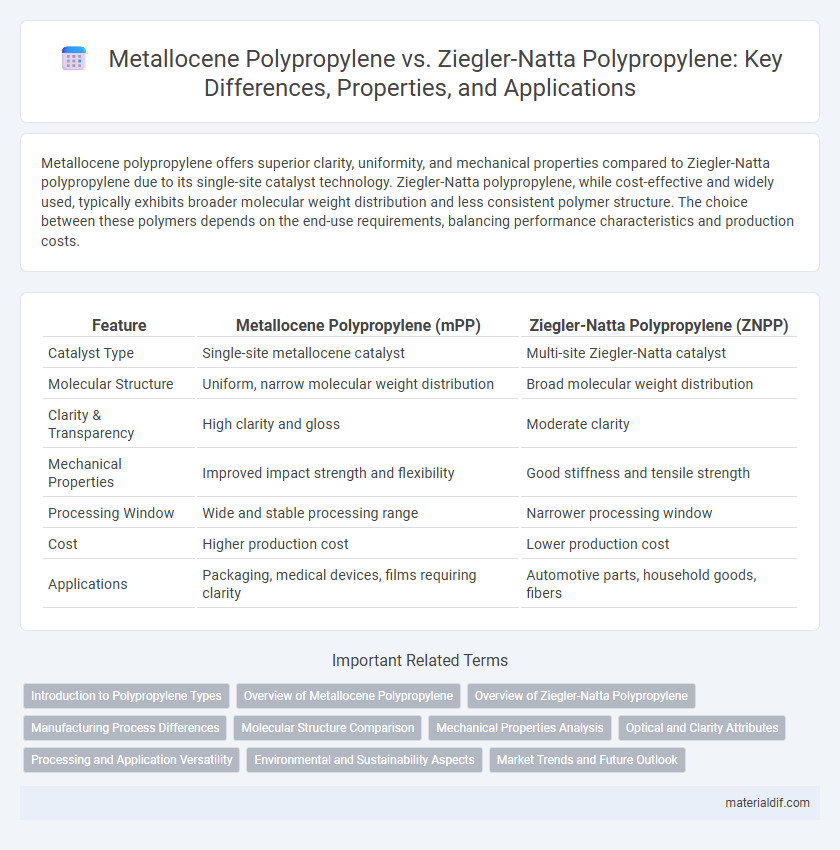

Metallocene polypropylene offers superior clarity, uniformity, and mechanical properties compared to Ziegler-Natta polypropylene due to its single-site catalyst technology. Ziegler-Natta polypropylene, while cost-effective and widely used, typically exhibits broader molecular weight distribution and less consistent polymer structure. The choice between these polymers depends on the end-use requirements, balancing performance characteristics and production costs.

Table of Comparison

| Feature | Metallocene Polypropylene (mPP) | Ziegler-Natta Polypropylene (ZNPP) |

|---|---|---|

| Catalyst Type | Single-site metallocene catalyst | Multi-site Ziegler-Natta catalyst |

| Molecular Structure | Uniform, narrow molecular weight distribution | Broad molecular weight distribution |

| Clarity & Transparency | High clarity and gloss | Moderate clarity |

| Mechanical Properties | Improved impact strength and flexibility | Good stiffness and tensile strength |

| Processing Window | Wide and stable processing range | Narrower processing window |

| Cost | Higher production cost | Lower production cost |

| Applications | Packaging, medical devices, films requiring clarity | Automotive parts, household goods, fibers |

Introduction to Polypropylene Types

Metallocene polypropylene offers superior clarity, enhanced impact strength, and improved uniformity compared to Ziegler-Natta polypropylene, which is known for cost-effectiveness and wide industrial use. The metallocene catalyst enables precise control over polymer structure, resulting in tailored physical properties for advanced applications. Ziegler-Natta polypropylene remains dominant in commodity markets due to its established processing methods and balanced performance characteristics.

Overview of Metallocene Polypropylene

Metallocene polypropylene is produced using metallocene catalysts, allowing precise control over polymer structure and resulting in superior clarity, softness, and impact resistance compared to conventional Ziegler-Natta polypropylene. This type of polypropylene exhibits uniform molecular weight distribution and tailored tacticity, enhancing mechanical properties and processability for high-performance applications such as packaging and automotive components. The advanced catalyst system enables production of specialty grades with improved optical properties and versatility in film, fiber, and injection molding uses.

Overview of Ziegler-Natta Polypropylene

Ziegler-Natta polypropylene is produced using traditional Ziegler-Natta catalysts, which enable stereoregular polymerization resulting in isotactic polypropylene with high crystallinity and mechanical strength. This type of polypropylene is widely used in packaging, automotive components, and consumer goods due to its balanced cost-performance ratio and excellent processability. Although it has lower clarity and impact resistance compared to metallocene polypropylene, its mature technology ensures consistent product quality and large-scale manufacturing efficiency.

Manufacturing Process Differences

Metallocene polypropylene is produced using single-site metallocene catalysts that offer precise molecular weight distribution and uniform polymer structure, resulting in enhanced clarity and mechanical properties. In contrast, Ziegler-Natta polypropylene is synthesized with heterogeneous multi-site catalysts, leading to broader molecular weight distribution and varied polymer chain branching. The metallocene process allows for greater control over polymer architecture, enabling tailored performance characteristics unattainable with conventional Ziegler-Natta catalysts.

Molecular Structure Comparison

Metallocene polypropylene exhibits a highly uniform molecular structure with narrow molecular weight distribution and isotacticity, resulting from single-site catalyst polymerization. In contrast, Ziegler-Natta polypropylene features a broader molecular weight distribution and more heterogeneous molecular structure due to multi-site catalysts. The superior control over chain architecture in metallocene polypropylene enhances mechanical properties, clarity, and processability compared to Ziegler-Natta polypropylene.

Mechanical Properties Analysis

Metallocene polypropylene exhibits superior mechanical properties compared to Ziegler-Natta polypropylene, offering enhanced tensile strength, clarity, and toughness due to its uniform molecular weight distribution and precise polymer chain control. Ziegler-Natta polypropylene, while cost-effective, presents a broader molecular weight distribution resulting in lower impact resistance and less stiffness. The controlled polymer architecture of metallocene catalysts leads to improved impact strength and elongation at break, making it ideal for applications requiring higher mechanical performance.

Optical and Clarity Attributes

Metallocene polypropylene offers superior optical properties compared to Ziegler-Natta polypropylene, with higher clarity and gloss due to its uniform molecular structure and narrower molecular weight distribution. The enhanced isotacticity of metallocene polypropylene results in reduced haze and improved transparency, making it ideal for packaging applications requiring excellent visual appeal. Ziegler-Natta polypropylene typically exhibits lower clarity, with a more heterogeneous structure that can cause increased opacity and reduced gloss.

Processing and Application Versatility

Metallocene polypropylene exhibits superior processing characteristics, including enhanced clarity, improved impact resistance, and more precise molecular weight distribution compared to Ziegler-Natta polypropylene. This allows for greater application versatility in packaging films, automotive components, and medical devices where high performance and aesthetic quality are critical. Ziegler-Natta polypropylene remains favored for cost-effectiveness and broader availability in commodity applications such as injection molding and fiber production.

Environmental and Sustainability Aspects

Metallocene polypropylene offers enhanced environmental benefits due to its precise molecular control, resulting in improved recyclability and reduced waste during production compared to Ziegler-Natta polypropylene. Ziegler-Natta polypropylene, while widely used, often generates higher catalyst residues and increased volatile organic compound emissions, impacting its sustainability profile. The cleaner catalyst system and lower energy consumption of metallocene polypropylene contribute significantly to its eco-friendlier lifecycle and reduced carbon footprint.

Market Trends and Future Outlook

Metallocene polypropylene exhibits superior clarity, stiffness, and impact resistance compared to Ziegler-Natta polypropylene, driving its growing adoption in packaging, automotive, and medical sectors. Market trends indicate increasing demand for metallocene-based polypropylene due to its enhanced performance and customization capabilities, while Ziegler-Natta catalysts remain dominant for cost-sensitive applications. Future outlooks predict metallocene polypropylene will capture a larger market share, fueled by innovations in catalyst technology and sustainability-driven product development.

Metallocene Polypropylene vs Ziegler-Natta Polypropylene Infographic

materialdif.com

materialdif.com