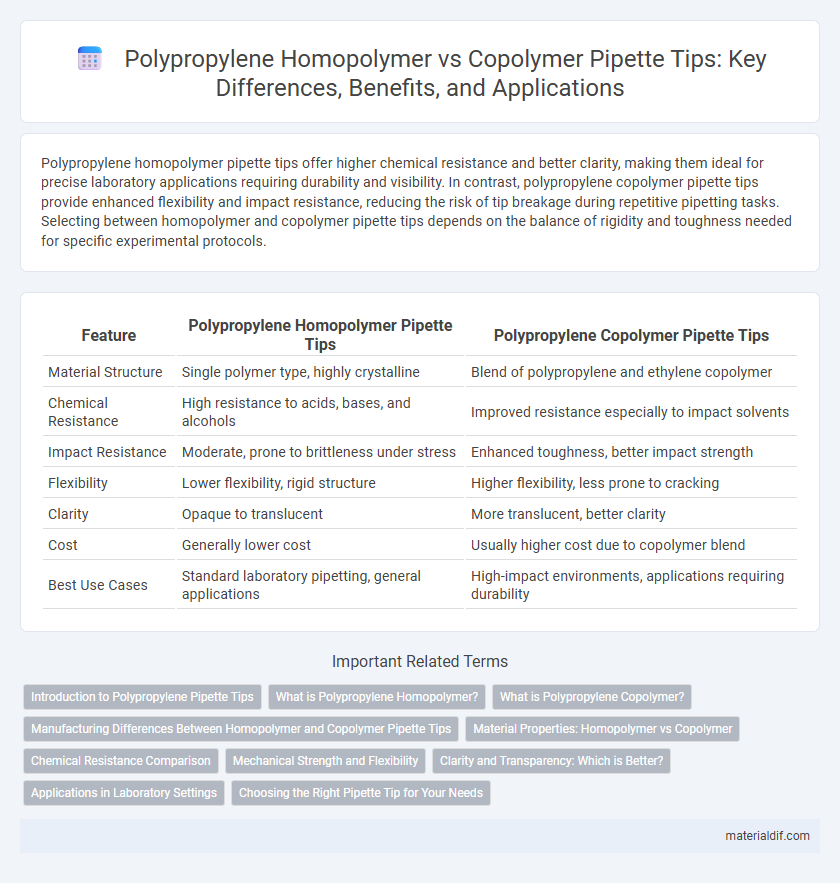

Polypropylene homopolymer pipette tips offer higher chemical resistance and better clarity, making them ideal for precise laboratory applications requiring durability and visibility. In contrast, polypropylene copolymer pipette tips provide enhanced flexibility and impact resistance, reducing the risk of tip breakage during repetitive pipetting tasks. Selecting between homopolymer and copolymer pipette tips depends on the balance of rigidity and toughness needed for specific experimental protocols.

Table of Comparison

| Feature | Polypropylene Homopolymer Pipette Tips | Polypropylene Copolymer Pipette Tips |

|---|---|---|

| Material Structure | Single polymer type, highly crystalline | Blend of polypropylene and ethylene copolymer |

| Chemical Resistance | High resistance to acids, bases, and alcohols | Improved resistance especially to impact solvents |

| Impact Resistance | Moderate, prone to brittleness under stress | Enhanced toughness, better impact strength |

| Flexibility | Lower flexibility, rigid structure | Higher flexibility, less prone to cracking |

| Clarity | Opaque to translucent | More translucent, better clarity |

| Cost | Generally lower cost | Usually higher cost due to copolymer blend |

| Best Use Cases | Standard laboratory pipetting, general applications | High-impact environments, applications requiring durability |

Introduction to Polypropylene Pipette Tips

Polypropylene homopolymer pipette tips offer higher chemical resistance and rigidity, making them ideal for precise liquid handling in demanding laboratory applications. Polypropylene copolymer pipette tips provide enhanced flexibility and impact resistance, reducing tip breakage during repetitive use. Both types ensure low protein binding and excellent clarity, essential for accurate pipetting and contamination control in molecular biology and clinical settings.

What is Polypropylene Homopolymer?

Polypropylene homopolymer is a type of polypropylene made from only propylene monomers, resulting in a highly crystalline and rigid material with excellent chemical resistance and high tensile strength. It is commonly used for pipette tips due to its durability, low moisture absorption, and ability to maintain structural integrity during repeated use and sterilization. Compared to polypropylene copolymer, homopolymer offers greater stiffness and higher melting point, making it ideal for applications demanding precise liquid handling and robustness.

What is Polypropylene Copolymer?

Polypropylene copolymer is a type of polypropylene made by polymerizing propylene with other monomers such as ethylene, resulting in improved impact resistance and flexibility compared to homopolymer polypropylene. This enhanced mechanical performance reduces brittleness at low temperatures, making copolymer pipette tips more durable under rigorous laboratory conditions. Unlike polypropylene homopolymer tips, copolymer tips offer superior resistance to cracking and are ideal for applications requiring repeated pipetting and exposure to temperature variations.

Manufacturing Differences Between Homopolymer and Copolymer Pipette Tips

Polypropylene homopolymer pipette tips are manufactured using a single type of polypropylene resin, resulting in a material with higher crystallinity and increased rigidity, which provides excellent chemical resistance and durability. In contrast, copolymer pipette tips are produced by combining polypropylene with another monomer, often ethylene, to enhance flexibility and impact resistance without compromising overall strength. The manufacturing process of homopolymer tips focuses on achieving uniform polymer chains for rigidity, while copolymer tips require precise blending and extrusion to ensure consistent material properties and improved performance in variable laboratory environments.

Material Properties: Homopolymer vs Copolymer

Polypropylene homopolymer pipette tips exhibit higher crystallinity, resulting in enhanced chemical resistance and rigidity, making them suitable for precise liquid handling in demanding laboratory environments. In contrast, polypropylene copolymer pipette tips offer greater impact resistance and flexibility due to the incorporation of ethylene segments, reducing brittleness and improving durability under mechanical stress. Selection between homopolymer and copolymer materials depends on application needs, balancing stiffness and chemical tolerance against toughness and resilience.

Chemical Resistance Comparison

Polypropylene homopolymer pipette tips exhibit superior chemical resistance to a broad range of solvents, acids, and bases, making them ideal for handling aggressive reagents in laboratory settings. In contrast, polypropylene copolymer pipette tips offer enhanced impact resistance but slightly lower chemical resistance due to the incorporation of ethylene units. Selecting homopolymer tips is preferable when strong chemical durability is critical, especially for use with concentrated acids or organic solvents.

Mechanical Strength and Flexibility

Polypropylene homopolymer pipette tips exhibit higher mechanical strength due to their crystalline structure, making them more resistant to deformation under stress. In contrast, polypropylene copolymer pipette tips contain elastomeric blocks that enhance flexibility and impact resistance but slightly reduce overall rigidity. Choosing between homopolymer and copolymer tips depends on the need for maximum durability or improved flexibility in pipetting applications.

Clarity and Transparency: Which is Better?

Polypropylene homopolymer pipette tips offer superior clarity and transparency compared to copolymer alternatives, ensuring precise visual monitoring of liquid samples. The homopolymer structure provides a higher optical purity, minimizing cloudiness and enhancing readability during laboratory procedures. Copolymer tips, while more impact-resistant, typically exhibit a slight haziness that can hinder accurate observation in critical applications.

Applications in Laboratory Settings

Polypropylene homopolymer pipette tips offer superior chemical resistance and are ideal for precise liquid handling in molecular biology and biochemistry applications due to their high purity and low extractables. In contrast, polypropylene copolymer pipette tips provide enhanced impact resistance and flexibility, making them suitable for repetitive pipetting tasks and handling viscous liquids in clinical and diagnostic laboratories. Selecting between homopolymer and copolymer tips depends on the specific laboratory requirements, balancing chemical compatibility and mechanical robustness.

Choosing the Right Pipette Tip for Your Needs

Polypropylene homopolymer pipette tips offer higher chemical resistance and are ideal for precise liquid handling in environments requiring purity and minimal contamination. Polypropylene copolymer pipette tips provide enhanced flexibility and durability, reducing tip breakage during repetitive use in high-throughput laboratories. Selecting the right pipette tip depends on the balance between chemical compatibility, sample integrity, and mechanical strength required for specific laboratory applications.

Polypropylene Homopolymer Pipette Tips vs Polypropylene Copolymer Pipette Tips Infographic

materialdif.com

materialdif.com