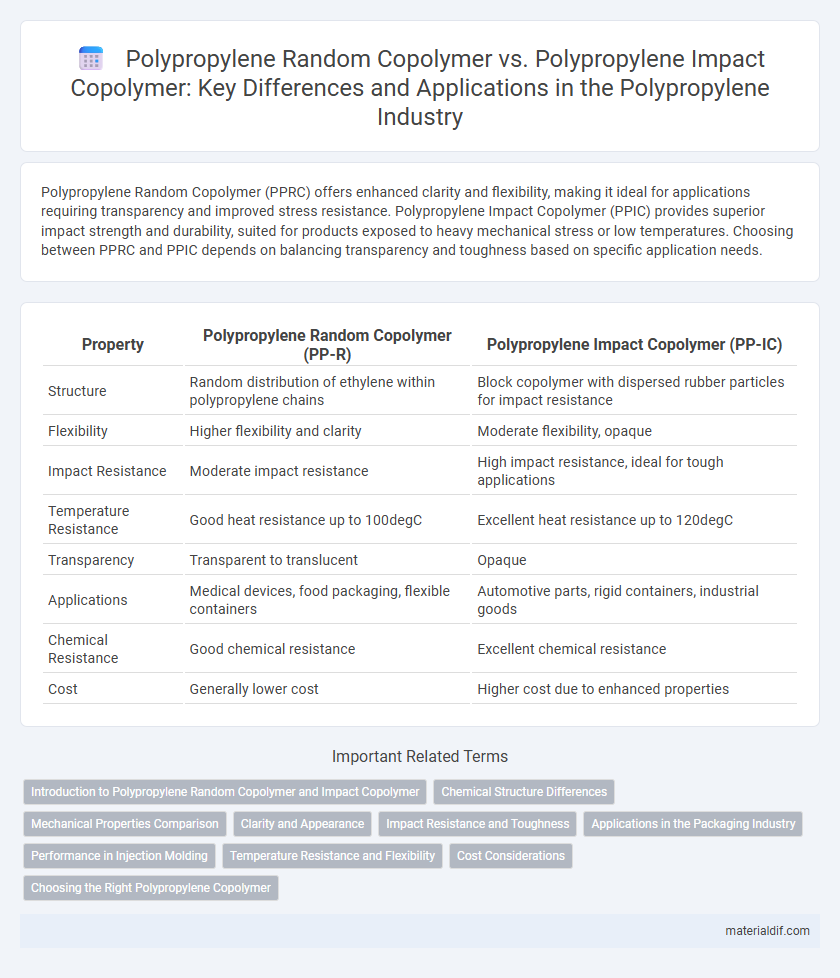

Polypropylene Random Copolymer (PPRC) offers enhanced clarity and flexibility, making it ideal for applications requiring transparency and improved stress resistance. Polypropylene Impact Copolymer (PPIC) provides superior impact strength and durability, suited for products exposed to heavy mechanical stress or low temperatures. Choosing between PPRC and PPIC depends on balancing transparency and toughness based on specific application needs.

Table of Comparison

| Property | Polypropylene Random Copolymer (PP-R) | Polypropylene Impact Copolymer (PP-IC) |

|---|---|---|

| Structure | Random distribution of ethylene within polypropylene chains | Block copolymer with dispersed rubber particles for impact resistance |

| Flexibility | Higher flexibility and clarity | Moderate flexibility, opaque |

| Impact Resistance | Moderate impact resistance | High impact resistance, ideal for tough applications |

| Temperature Resistance | Good heat resistance up to 100degC | Excellent heat resistance up to 120degC |

| Transparency | Transparent to translucent | Opaque |

| Applications | Medical devices, food packaging, flexible containers | Automotive parts, rigid containers, industrial goods |

| Chemical Resistance | Good chemical resistance | Excellent chemical resistance |

| Cost | Generally lower cost | Higher cost due to enhanced properties |

Introduction to Polypropylene Random Copolymer and Impact Copolymer

Polypropylene Random Copolymer (PPR) consists of propylene copolymerized with ethylene in a random sequence, resulting in a material with enhanced clarity, flexibility, and impact resistance compared to homopolymer polypropylene. Polypropylene Impact Copolymer (PPI) combines a polypropylene matrix with dispersed ethylene-propylene rubber particles, significantly improving toughness and impact strength, especially at low temperatures. Both copolymers are widely used in packaging, automotive parts, and consumer goods, where durability and performance under stress are critical.

Chemical Structure Differences

Polypropylene Random Copolymer (PPRC) features a random distribution of ethylene units within the polypropylene matrix, enhancing flexibility and clarity. Conversely, Polypropylene Impact Copolymer (PPIC) contains distinct ethylene-rich rubbery phases dispersed in a polypropylene matrix, significantly improving impact resistance. The microstructural difference lies in PPRC's uniform copolymerization versus PPIC's phase-separated morphology.

Mechanical Properties Comparison

Polypropylene Random Copolymer (PPRC) offers superior clarity and flexibility with a tensile strength typically around 32 MPa, making it ideal for applications requiring enhanced ductility. Polypropylene Impact Copolymer (PPIC) combines a tougher propylene matrix with ethylene-propylene rubber particles, delivering higher impact resistance up to 400 kJ/m2, especially at low temperatures. While PPRC provides better processability and surface finish, PPIC excels in mechanical toughness and durability under stress.

Clarity and Appearance

Polypropylene Random Copolymer (PPRC) offers superior clarity and a more transparent appearance compared to Polypropylene Impact Copolymer (PPIC), making it ideal for applications requiring aesthetic appeal. PPRC's homogeneous molecular structure reduces haze, enhancing its optical properties, while PPIC contains rubber phase particles that lead to a more opaque and matte finish. This distinction influences packaging, medical devices, and consumer products where visual quality is critical.

Impact Resistance and Toughness

Polypropylene Random Copolymer (PPRC) offers excellent clarity and flexibility but has lower impact resistance compared to Polypropylene Impact Copolymer (PPIC). PPIC features a higher ethylene content and a rubber phase, providing superior impact toughness, especially at low temperatures. This enhanced impact resistance makes PPIC ideal for applications requiring durability and mechanical stress absorption.

Applications in the Packaging Industry

Polypropylene Random Copolymer (PPRC) is widely used in flexible packaging applications such as food wrappers and bags due to its clarity, flexibility, and excellent heat seal properties. Polypropylene Impact Copolymer (PPIC) offers superior impact resistance and toughness, making it ideal for rigid packaging applications like containers, caps, and closures that require durability and impact strength. Both materials enhance product protection and shelf appeal, with PPRC favoring lightweight, transparent films and PPIC preferred for robust, high-performance packaging solutions.

Performance in Injection Molding

Polypropylene Random Copolymer (PPRC) offers superior clarity and flexibility in injection molding, making it ideal for applications requiring aesthetic appeal and moderate mechanical strength. Polypropylene Impact Copolymer (PPIC) provides enhanced impact resistance and toughness due to its rubber-modified structure, which improves durability in high-stress molded parts. The choice between PPRC and PPIC depends on the balance between optical properties and impact performance required in specific injection molding applications.

Temperature Resistance and Flexibility

Polypropylene Random Copolymer (PPR) demonstrates superior flexibility at low temperatures, maintaining pliability down to -10degC, making it ideal for applications requiring resilience in colder environments. Polypropylene Impact Copolymer (PPI) offers enhanced temperature resistance, sustaining mechanical performance up to 90degC, and exhibits higher impact strength due to its rubber-modified structure. The choice between PPR and PPI depends on the balance needed between flexibility under cold conditions and durability at elevated temperatures.

Cost Considerations

Polypropylene Random Copolymer (PPRC) typically incurs higher raw material costs due to its enhanced clarity and flexibility compared to Polypropylene Impact Copolymer (PPIC), which is engineered for superior impact resistance at a lower price point. Manufacturing processes for PPRC often require more precise control, increasing production expenses relative to PPIC's more robust, cost-effective injection molding techniques. Evaluating the total cost of ownership, including material performance and application-specific durability, is crucial for selecting between PPRC and PPIC in budget-sensitive projects.

Choosing the Right Polypropylene Copolymer

Polypropylene Random Copolymer offers superior clarity, flexibility, and heat resistance, making it ideal for applications requiring transparency and thermal stability. Polypropylene Impact Copolymer provides enhanced toughness and impact resistance, suitable for demanding mechanical and automotive parts. Selecting the right polypropylene copolymer depends on balancing the need for optical properties and thermal endurance against strength and impact performance.

Polypropylene Random Copolymer vs Polypropylene Impact Copolymer Infographic

materialdif.com

materialdif.com