Medical-grade polypropylene is manufactured under stringent regulations to ensure biocompatibility, sterility, and resistance to high temperatures, making it suitable for use in medical devices and pharmaceutical packaging. Food-grade polypropylene meets safety standards set for food contact, emphasizing non-toxicity and resistance to contamination, which is essential for packaging and storage of consumables. While both types share similar chemical properties, medical-grade polypropylene undergoes more rigorous testing to certify its suitability for healthcare applications.

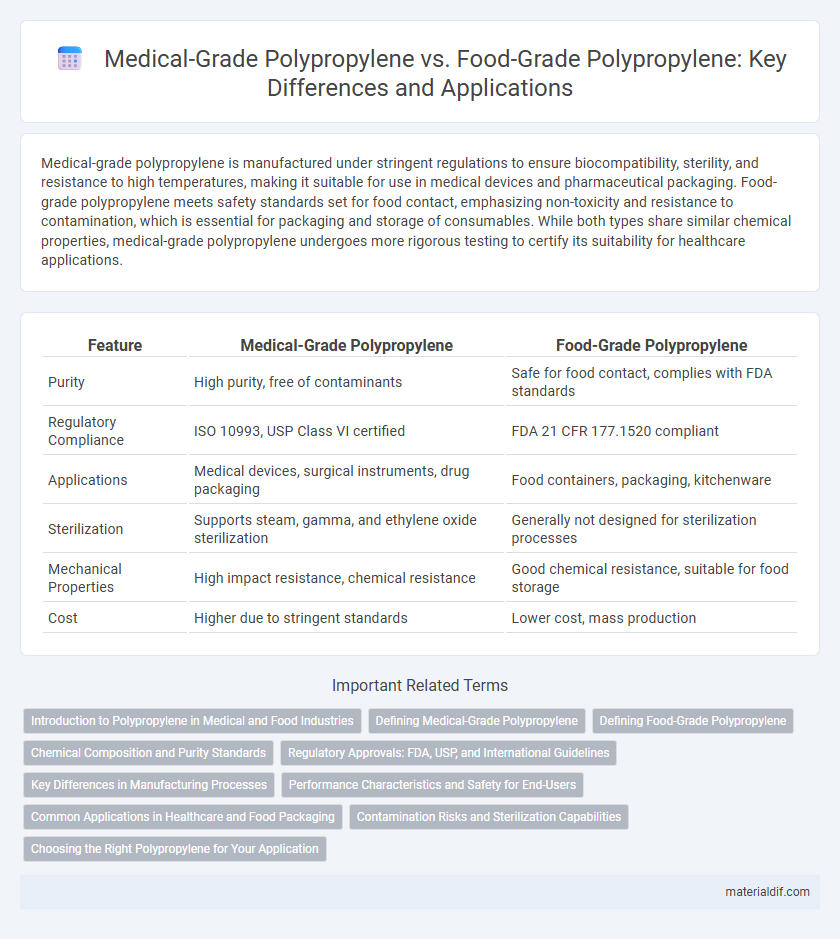

Table of Comparison

| Feature | Medical-Grade Polypropylene | Food-Grade Polypropylene |

|---|---|---|

| Purity | High purity, free of contaminants | Safe for food contact, complies with FDA standards |

| Regulatory Compliance | ISO 10993, USP Class VI certified | FDA 21 CFR 177.1520 compliant |

| Applications | Medical devices, surgical instruments, drug packaging | Food containers, packaging, kitchenware |

| Sterilization | Supports steam, gamma, and ethylene oxide sterilization | Generally not designed for sterilization processes |

| Mechanical Properties | High impact resistance, chemical resistance | Good chemical resistance, suitable for food storage |

| Cost | Higher due to stringent standards | Lower cost, mass production |

Introduction to Polypropylene in Medical and Food Industries

Medical-grade polypropylene is engineered to meet stringent regulatory standards for biocompatibility, sterilization tolerance, and chemical resistance, making it ideal for surgical instruments, drug delivery devices, and healthcare packaging. Food-grade polypropylene complies with FDA regulations for food safety, ensuring it is free from harmful contaminants and suitable for packaging, storage, and processing of consumables. Both grades offer excellent durability, chemical stability, and thermal resistance, but medical-grade polypropylene requires additional certifications and testing to guarantee patient safety and sterility.

Defining Medical-Grade Polypropylene

Medical-grade polypropylene is a highly purified form of polypropylene designed to meet stringent biocompatibility and sterilization standards for use in medical devices and surgical applications. It undergoes rigorous testing to ensure it is free from harmful additives and contaminants, making it safe for direct contact with tissues and fluids. Unlike food-grade polypropylene, which primarily complies with FDA regulations for food safety, medical-grade polypropylene meets additional criteria for mechanical strength, chemical resistance, and sterilization compatibility required in healthcare environments.

Defining Food-Grade Polypropylene

Food-grade polypropylene is a type of polypropylene specifically formulated and tested to meet safety standards set by regulatory agencies such as the FDA for direct contact with food and beverages. This material exhibits high chemical resistance, low toxicity, and the ability to withstand repeated sterilization processes without degrading its properties. Unlike medical-grade polypropylene, which requires stringent biocompatibility and sterilization criteria for medical applications, food-grade polypropylene prioritizes food safety, odor resistance, and maintaining flavor integrity during storage and handling.

Chemical Composition and Purity Standards

Medical-grade polypropylene is formulated with higher purity and stringent chemical composition standards to ensure biocompatibility and absence of toxic additives, making it suitable for direct contact with tissues and sterilization processes. Food-grade polypropylene meets regulatory limits for residual monomers and additives to prevent contamination but does not require the same level of sterility or biocompatibility as medical-grade variants. Both types are primarily composed of isotactic polypropylene resin, but medical-grade polypropylene undergoes more rigorous testing to guarantee its chemical stability and purity for medical applications.

Regulatory Approvals: FDA, USP, and International Guidelines

Medical-grade polypropylene complies with stringent regulatory approvals including FDA 21 CFR 177.1520 and USP Class VI standards, ensuring biocompatibility and safety for medical applications such as surgical instruments and implantable devices. Food-grade polypropylene meets FDA regulations for food contact materials (FDA 21 CFR 177.1520) and adheres to international standards like EU Regulation No. 10/2011, guaranteeing non-toxicity and contamination-free packaging for food products. Both grades follow rigorous testing protocols aligned with global guidelines to certify their suitability for specific uses, emphasizing differences in purity, sterilization compatibility, and additive restrictions.

Key Differences in Manufacturing Processes

Medical-grade polypropylene undergoes stringent sterilization and purity protocols during manufacturing to meet biocompatibility and regulatory standards such as ISO 10993 and USP Class VI, ensuring it is free from toxins and contaminants. Food-grade polypropylene is produced with FDA-compliant additives that prevent chemical migration into food products, focusing on maintaining safety and taste without requiring the same level of sterility. The manufacturing of medical-grade polypropylene typically involves enhanced quality control measures, including cleanroom environments and advanced filtration systems, distinguishing it from the less rigorous processes used for food-grade polypropylene.

Performance Characteristics and Safety for End-Users

Medical-grade polypropylene exhibits superior biocompatibility, ensuring it meets stringent regulations such as ISO 10993 for safe contact with human tissues, making it ideal for surgical instruments and implantable devices. Food-grade polypropylene complies with FDA regulations 21 CFR 177.1520, ensuring it is free from harmful substances, and demonstrates excellent resistance to chemicals and high temperatures suitable for food packaging and containers. Both grades offer durability and chemical resistance, but medical-grade polypropylene prioritizes sterility and non-toxicity critical for patient safety, while food-grade polypropylene focuses on preventing contamination and preserving food quality.

Common Applications in Healthcare and Food Packaging

Medical-grade polypropylene is used extensively in healthcare for manufacturing syringes, medical vials, diagnostic equipment, and surgical instruments due to its high purity, biocompatibility, and resistance to sterilization methods like autoclaving. Food-grade polypropylene is commonly utilized in food packaging applications such as containers, films, and microwaveable trays because it meets stringent FDA regulations for food contact safety and provides excellent chemical resistance and moisture barrier properties. Both types offer durability and chemical stability but are tailored specifically to meet the safety and regulatory requirements of their respective industries.

Contamination Risks and Sterilization Capabilities

Medical-grade polypropylene is engineered to meet stringent contamination control standards, ensuring biocompatibility and resistance to bacterial ingress, which is critical for sterile medical environments. Food-grade polypropylene, while safe for food contact, may not offer the same level of sterilization capability or resistance to contamination required in medical applications. The sterilization methods compatible with medical-grade polypropylene, such as autoclaving and gamma irradiation, help maintain material integrity and minimize contamination risks, unlike some food-grade variants that may degrade under these sterilization processes.

Choosing the Right Polypropylene for Your Application

Medical-grade polypropylene meets stringent FDA and ISO standards for biocompatibility and sterilization, making it ideal for surgical instruments, medical devices, and pharmaceutical containers. Food-grade polypropylene complies with FDA and EU regulations for food contact safety, ensuring no harmful chemicals leach into food products during storage or processing. Selecting the right polypropylene depends on specific application requirements such as sterilization methods, chemical resistance, and regulatory compliance.

Medical-Grade Polypropylene vs Food-Grade Polypropylene Infographic

materialdif.com

materialdif.com