BOPP film offers superior clarity, stiffness, and moisture resistance compared to cast PP film, making it ideal for packaging applications requiring high optical quality and durability. Cast PP film features a softer feel and better sealability due to its unique manufacturing process, which results in enhanced flexibility and printability. Choice between BOPP and cast PP films depends largely on specific end-use demands such as barrier properties, visual aesthetics, and mechanical strength.

Table of Comparison

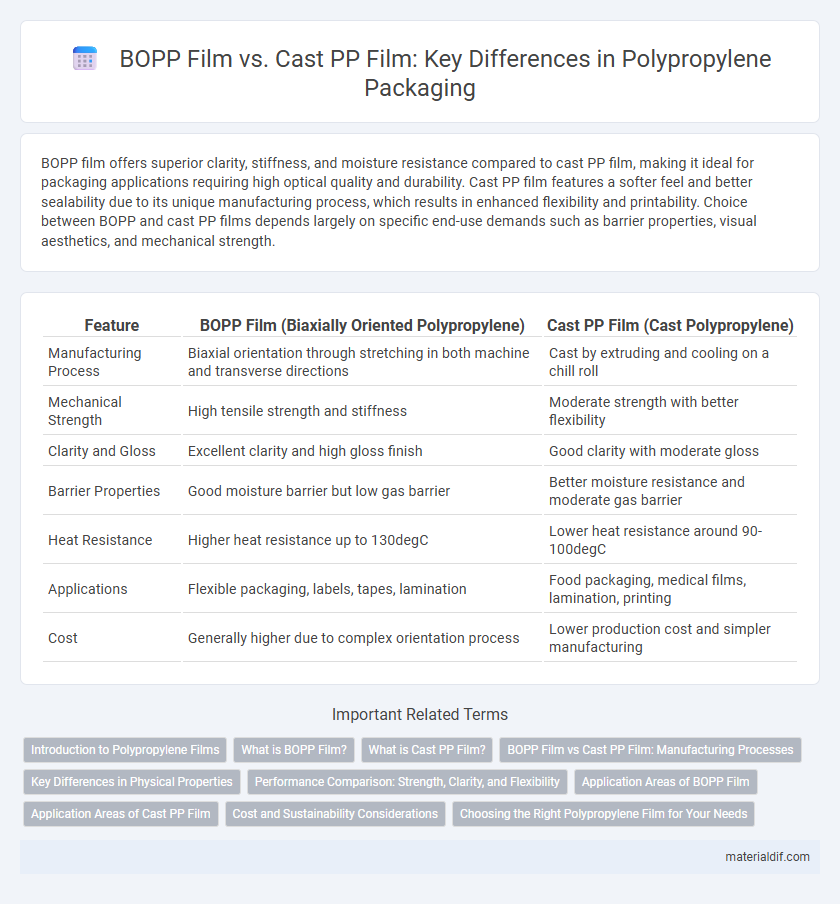

| Feature | BOPP Film (Biaxially Oriented Polypropylene) | Cast PP Film (Cast Polypropylene) |

|---|---|---|

| Manufacturing Process | Biaxial orientation through stretching in both machine and transverse directions | Cast by extruding and cooling on a chill roll |

| Mechanical Strength | High tensile strength and stiffness | Moderate strength with better flexibility |

| Clarity and Gloss | Excellent clarity and high gloss finish | Good clarity with moderate gloss |

| Barrier Properties | Good moisture barrier but low gas barrier | Better moisture resistance and moderate gas barrier |

| Heat Resistance | Higher heat resistance up to 130degC | Lower heat resistance around 90-100degC |

| Applications | Flexible packaging, labels, tapes, lamination | Food packaging, medical films, lamination, printing |

| Cost | Generally higher due to complex orientation process | Lower production cost and simpler manufacturing |

Introduction to Polypropylene Films

Polypropylene films, including BOPP (Biaxially Oriented Polypropylene) and Cast PP (Cast Polypropylene), are widely used in packaging due to their excellent clarity, strength, and moisture resistance. BOPP film undergoes biaxial orientation, enhancing tensile strength and barrier properties, making it ideal for flexible packaging and labeling. Cast PP film is produced by casting onto a chill roll, resulting in a softer, more transparent film with high gloss, suitable for lamination and printing applications.

What is BOPP Film?

BOPP film, or Biaxially Oriented Polypropylene film, is a versatile plastic film stretched in both machine and transverse directions to enhance strength, clarity, and barrier properties. It is widely used in packaging applications due to its superb tensile strength, moisture resistance, and excellent printability. Compared to Cast PP film, BOPP offers better dimensional stability and stiffness, making it ideal for high-performance labeling and flexible packaging solutions.

What is Cast PP Film?

Cast PP film is a type of polypropylene film produced through a casting process where molten polymer is extruded onto chill rolls, resulting in a smooth, high-clarity film with superior optical properties. Unlike BOPP film, which is biaxially stretched to enhance strength and stiffness, cast PP film offers excellent printability, good barrier properties, and flexibility, making it ideal for packaging applications requiring clarity and softness. This film type also provides resistance to moisture and chemicals, contributing to its widespread use in labels, laminations, and flexible packaging.

BOPP Film vs Cast PP Film: Manufacturing Processes

BOPP film is produced through a biaxial orientation process where polypropylene sheets are stretched both longitudinally and transversely, enhancing its tensile strength and clarity. Cast PP film manufacturing involves melting polypropylene and extruding it onto chilled rollers, resulting in a smooth, uniform film with excellent moisture barrier properties. Differences in these processes impact the films' mechanical characteristics, surface finish, and suitability for various packaging applications.

Key Differences in Physical Properties

BOPP film exhibits higher tensile strength and superior clarity due to its biaxial orientation process, enhancing barrier properties against moisture and gases. Cast PP film, produced through a casting method, offers better dimensional stability and heat resistance but lower tensile strength and clarity compared to BOPP. The choice between BOPP and Cast PP films depends on specific application requirements such as flexibility, optical properties, and thermal performance.

Performance Comparison: Strength, Clarity, and Flexibility

BOPP film exhibits superior tensile strength and excellent clarity due to its biaxial orientation, making it ideal for packaging that requires durability and high visual appeal. Cast PP film offers enhanced flexibility and a smoother surface, providing better conformability and heat-sealing properties compared to BOPP. While BOPP excels in mechanical strength and stiffness, cast PP film is preferred for applications demanding softer touch and superior gloss.

Application Areas of BOPP Film

BOPP film is extensively used in packaging for food products, offering superior moisture resistance and clarity compared to Cast PP film, making it ideal for snacks, confectionery, and fresh produce. Its high tensile strength and excellent printability support applications in labels, lamination, and adhesive tapes within the consumer goods industry. BOPP film's moisture barrier and optical properties make it a preferred choice in medical and pharmaceutical packaging for ensuring product protection and shelf appeal.

Application Areas of Cast PP Film

Cast PP film is extensively used in packaging applications such as laminating flexible packaging, food wrappers, and labels due to its excellent clarity, gloss, and moisture barrier properties. It also finds application in stationary films, book covers, and lamination for surface protection in industrial uses. The film's superior stiffness and dimensional stability make it ideal for high-quality printing and heat sealing processes in the packaging industry.

Cost and Sustainability Considerations

BOPP film typically incurs higher production costs due to its biaxial orientation process, which enhances strength and clarity but requires more energy and specialized equipment compared to cast PP film. Cast PP film offers cost advantages with its simpler manufacturing process, consuming less energy and producing less waste, making it a more sustainable choice for large-volume packaging applications. However, BOPP's recyclability and longer lifespan can offset its initial environmental impact, highlighting a balance between cost efficiency and sustainability priorities in film selection.

Choosing the Right Polypropylene Film for Your Needs

BOPP film offers excellent clarity, superior moisture resistance, and high tensile strength, making it ideal for packaging applications requiring durability and visual appeal. Cast PP film provides better dimensional stability, a smoother surface, and enhanced printability, suitable for lamination and labeling needs. Selecting the right polypropylene film depends on balancing factors like barrier properties, mechanical strength, and intended use to optimize performance and cost-efficiency.

BOPP Film vs Cast PP Film Infographic

materialdif.com

materialdif.com