Unfilled polypropylene offers excellent flexibility, chemical resistance, and low density, making it ideal for applications requiring lightweight and impact-resistant materials. Glass-filled polypropylene enhances mechanical strength, stiffness, and dimensional stability by incorporating glass fibers, which improves performance in demanding structural components. Choosing between unfilled and glass-filled polypropylene depends on the balance between weight reduction and the need for increased durability and rigidity.

Table of Comparison

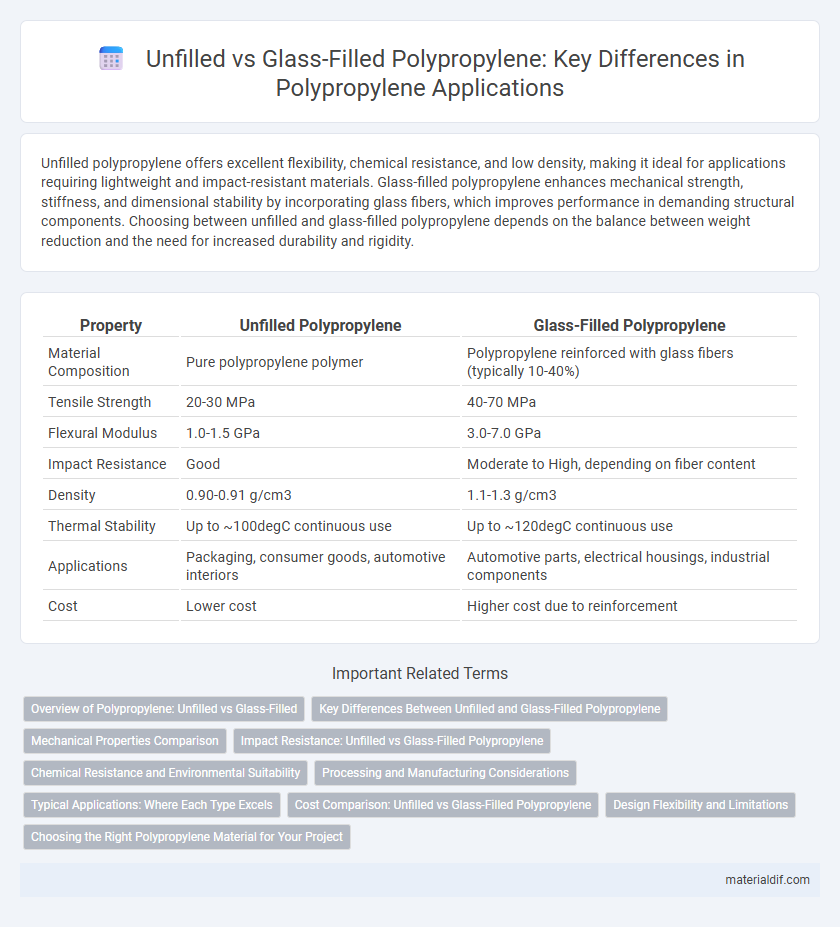

| Property | Unfilled Polypropylene | Glass-Filled Polypropylene |

|---|---|---|

| Material Composition | Pure polypropylene polymer | Polypropylene reinforced with glass fibers (typically 10-40%) |

| Tensile Strength | 20-30 MPa | 40-70 MPa |

| Flexural Modulus | 1.0-1.5 GPa | 3.0-7.0 GPa |

| Impact Resistance | Good | Moderate to High, depending on fiber content |

| Density | 0.90-0.91 g/cm3 | 1.1-1.3 g/cm3 |

| Thermal Stability | Up to ~100degC continuous use | Up to ~120degC continuous use |

| Applications | Packaging, consumer goods, automotive interiors | Automotive parts, electrical housings, industrial components |

| Cost | Lower cost | Higher cost due to reinforcement |

Overview of Polypropylene: Unfilled vs Glass-Filled

Unfilled polypropylene is a versatile thermoplastic polymer known for its flexibility, chemical resistance, and low cost, making it suitable for general-purpose applications such as packaging and consumer goods. Glass-filled polypropylene incorporates glass fibers, typically ranging from 10% to 40% by weight, significantly enhancing mechanical strength, stiffness, and heat resistance for demanding industrial uses like automotive parts and electrical components. The choice between unfilled and glass-filled polypropylene depends on specific performance requirements including impact resistance, dimensional stability, and thermal endurance.

Key Differences Between Unfilled and Glass-Filled Polypropylene

Unfilled polypropylene offers lightweight flexibility and higher impact resistance, making it ideal for applications requiring ease of molding and lower cost. Glass-filled polypropylene incorporates glass fibers, significantly enhancing tensile strength, dimensional stability, and heat resistance, which suits structural and automotive components. The key differences lie in mechanical properties, thermal performance, and cost, with glass-filled variants offering superior strength at increased weight and expense.

Mechanical Properties Comparison

Unfilled polypropylene exhibits lower tensile strength and impact resistance compared to glass-filled polypropylene, which incorporates glass fibers to significantly enhance stiffness, rigidity, and dimensional stability. Glass-filled polypropylene typically demonstrates improved flexural modulus and increased heat deflection temperature, making it suitable for applications requiring higher mechanical performance. The presence of glass fibers reduces elongation at break and improves wear resistance, optimizing the material for demanding structural components.

Impact Resistance: Unfilled vs Glass-Filled Polypropylene

Unfilled polypropylene exhibits higher impact resistance due to its inherent flexibility and ability to absorb energy without fracturing. Glass-filled polypropylene, while significantly stronger and more rigid, tends to have reduced impact resistance because the glass fibers create points of stress concentration that can lead to cracking under sudden impact. Selecting between unfilled and glass-filled polypropylene depends on the balance needed between toughness and structural strength for the application.

Chemical Resistance and Environmental Suitability

Unfilled polypropylene exhibits excellent chemical resistance, maintaining stability against acids, bases, and solvents, making it ideal for applications requiring corrosion resistance. Glass-filled polypropylene offers enhanced mechanical strength and thermal stability but can be more susceptible to chemical degradation in highly aggressive environments due to filler interactions. In terms of environmental suitability, unfilled polypropylene is better suited for reuse and recycling, while glass-filled variants provide improved durability in harsh conditions but pose challenges for recycling processes.

Processing and Manufacturing Considerations

Unfilled polypropylene offers simpler processing with lower melt viscosity, enabling faster cycle times and easier molding in injection molding and extrusion processes. Glass-filled polypropylene requires higher processing temperatures and pressures due to increased melt stiffness and abrasive nature of glass fibers, necessitating specialized equipment and wear-resistant tooling. Mold design must account for fiber orientation and shrinkage variations in glass-filled grades to ensure dimensional stability and mechanical performance.

Typical Applications: Where Each Type Excels

Unfilled polypropylene is commonly used in packaging, consumer goods, and medical devices due to its lightweight and chemical resistance. Glass-filled polypropylene offers enhanced mechanical strength and dimensional stability, making it ideal for automotive parts, industrial equipment, and electrical housings. Each type excels in applications where either flexibility and cost-effectiveness or increased rigidity and durability are essential.

Cost Comparison: Unfilled vs Glass-Filled Polypropylene

Unfilled polypropylene generally costs less due to the absence of reinforcing agents, making it ideal for budget-conscious applications requiring basic mechanical properties. Glass-filled polypropylene demands higher material and processing expenses because of the added glass fibers, which enhance strength and stiffness but increase overall production costs. Evaluating cost-effectiveness depends on balancing the improved performance characteristics of glass-filled polypropylene against the lower upfront price of unfilled variants.

Design Flexibility and Limitations

Unfilled polypropylene offers superior design flexibility due to its lower density and excellent mold flow, enabling the creation of intricate shapes and thin walls without compromising structural integrity. Glass-filled polypropylene enhances mechanical strength and rigidity but introduces limitations such as increased weight, reduced elongation, and potential warping during molding, restricting complex geometries. Designers must balance these trade-offs, choosing unfilled grades for applications prioritizing flexibility and glass-filled variants for parts demanding enhanced durability and dimensional stability.

Choosing the Right Polypropylene Material for Your Project

Choosing the right polypropylene material depends on the specific application requirements, where unfilled polypropylene offers excellent chemical resistance, flexibility, and impact strength ideal for lightweight or flexible components. Glass-filled polypropylene enhances rigidity, dimensional stability, and heat resistance, making it suitable for structural parts requiring higher mechanical strength and thermal performance. Evaluating factors such as load-bearing capacity, environmental exposure, and processing methods ensures optimal material selection between unfilled and glass-filled polypropylene for maximizing durability and functionality.

Unfilled Polypropylene vs Glass-Filled Polypropylene Infographic

materialdif.com

materialdif.com