Oriented Polypropylene (OPP) is a type of polypropylene film stretched in one direction to enhance its strength and clarity, making it suitable for packaging applications requiring flexibility and gloss. Biaxially Oriented Polypropylene (BOPP) undergoes stretching in both the machine and transverse directions, resulting in improved mechanical properties such as higher tensile strength, better barrier performance, and increased stiffness compared to OPP. The biaxial orientation in BOPP offers superior dimensional stability and resistance to moisture and chemicals, making it ideal for food packaging and labeling where durability and product protection are critical.

Table of Comparison

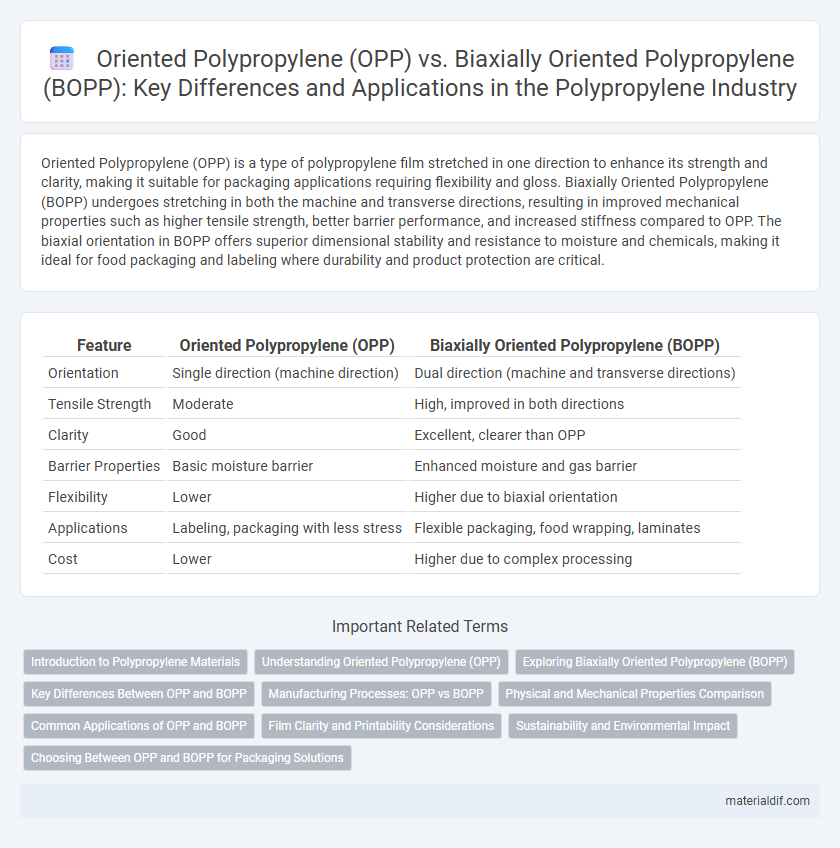

| Feature | Oriented Polypropylene (OPP) | Biaxially Oriented Polypropylene (BOPP) |

|---|---|---|

| Orientation | Single direction (machine direction) | Dual direction (machine and transverse directions) |

| Tensile Strength | Moderate | High, improved in both directions |

| Clarity | Good | Excellent, clearer than OPP |

| Barrier Properties | Basic moisture barrier | Enhanced moisture and gas barrier |

| Flexibility | Lower | Higher due to biaxial orientation |

| Applications | Labeling, packaging with less stress | Flexible packaging, food wrapping, laminates |

| Cost | Lower | Higher due to complex processing |

Introduction to Polypropylene Materials

Oriented Polypropylene (OPP) is a uniaxially stretched polypropylene film, mainly used for packaging due to its clarity, strength, and barrier properties. Biaxially Oriented Polypropylene (BOPP) enhances these characteristics by stretching the film both machine and transverse directions, offering improved tensile strength, stiffness, and moisture resistance. Both OPP and BOPP are popular polypropylene materials in packaging, with BOPP preferred for applications requiring superior durability and clarity.

Understanding Oriented Polypropylene (OPP)

Oriented Polypropylene (OPP) is a type of polypropylene film stretched predominantly in one direction to enhance tensile strength and optical clarity. This uniaxial orientation improves stiffness and barrier properties against moisture, making OPP suitable for packaging applications requiring durability and transparency. Unlike Biaxially Oriented Polypropylene (BOPP), which is stretched in both machine and transverse directions, OPP provides directional mechanical properties tailored to specific industrial uses.

Exploring Biaxially Oriented Polypropylene (BOPP)

Biaxially Oriented Polypropylene (BOPP) is a polypropylene film stretched in both the machine and transverse directions, enhancing tensile strength, clarity, and barrier properties compared to Oriented Polypropylene (OPP), which is stretched in only one direction. BOPP films exhibit improved mechanical properties, superior moisture resistance, and enhanced printability, making them ideal for flexible packaging, labeling, and lamination applications. The biaxial orientation process refines polymer crystallinity, resulting in films with excellent dimensional stability and high optical quality.

Key Differences Between OPP and BOPP

Oriented Polypropylene (OPP) is stretched in a single direction, providing high tensile strength along the orientation axis, while Biaxially Oriented Polypropylene (BOPP) is stretched in both machine and transverse directions, resulting in enhanced clarity, improved barrier properties, and balanced mechanical strength. BOPP films exhibit superior moisture resistance and stiffness compared to OPP, making them ideal for packaging applications requiring durability and protection. The biaxial orientation process significantly enhances BOPP's dimensional stability and optical qualities compared to uniaxially oriented OPP films.

Manufacturing Processes: OPP vs BOPP

Oriented Polypropylene (OPP) is manufactured by stretching polypropylene film in a single direction, typically the machine direction, which enhances tensile strength and clarity. Biaxially Oriented Polypropylene (BOPP) undergoes stretching in both the machine and transverse directions, resulting in superior mechanical properties such as higher tensile strength, improved barrier resistance, and better optical clarity. The sequential stretching process in BOPP requires more complex equipment and precise control over temperature and tension compared to the uniaxial orientation in OPP.

Physical and Mechanical Properties Comparison

Oriented Polypropylene (OPP) exhibits uniaxial orientation, resulting in enhanced tensile strength and stiffness primarily in the direction of orientation, whereas Biaxially Oriented Polypropylene (BOPP) undergoes stretching in both machine and transverse directions, offering superior dimensional stability, higher barrier properties, and balanced mechanical strength across axes. BOPP demonstrates improved clarity, toughness, and moisture resistance compared to OPP, making it preferred for packaging applications demanding durability and printability. The biaxial orientation process in BOPP also increases puncture resistance and impact strength, distinguishing it from the predominantly directional strength profile of OPP films.

Common Applications of OPP and BOPP

Oriented Polypropylene (OPP) films are commonly used in flexible packaging, labeling, and lamination due to their clarity, strength, and moisture resistance. Biaxially Oriented Polypropylene (BOPP) films are widely applied in food packaging, adhesive tapes, and stationary products because of their enhanced mechanical properties and superior barrier performance against oxygen and moisture. Both OPP and BOPP are valued in industrial applications where durability and printability are essential.

Film Clarity and Printability Considerations

Oriented Polypropylene (OPP) offers excellent film clarity with a smooth, glossy finish ideal for high-quality print applications, while Biaxially Oriented Polypropylene (BOPP) enhances mechanical strength and barrier properties by stretching polypropylene in both machine and transverse directions. BOPP films exhibit superior printability due to their balanced molecular orientation, enabling sharper image resolution and better ink adhesion compared to uniaxially oriented OPP. Film clarity in BOPP is slightly reduced relative to OPP but remains adequate for most packaging needs where durability and print quality are prioritized.

Sustainability and Environmental Impact

Oriented Polypropylene (OPP) and Biaxially Oriented Polypropylene (BOPP) differ in their sustainability profiles due to manufacturing processes and end-use applications. BOPP films, stretched in both machine and transverse directions, provide enhanced strength and barrier properties, enabling thinner packaging that reduces material consumption and waste compared to uniaxially oriented OPP. The recyclability of both OPP and BOPP contributes positively to environmental impact, but BOPP's superior durability extends product shelf life, helping decrease food waste and associated carbon footprint.

Choosing Between OPP and BOPP for Packaging Solutions

Oriented Polypropylene (OPP) offers excellent clarity and stiffness, making it ideal for packaging that requires high optical properties and moderate mechanical strength. Biaxially Oriented Polypropylene (BOPP) enhances barrier properties and tensile strength in both machine and transverse directions, improving moisture resistance and durability for extended shelf life. Choosing between OPP and BOPP depends on the packaging requirements for clarity versus barrier performance, with BOPP preferred for food packaging and OPP suitable for flexible wrapping applications.

Oriented Polypropylene (OPP) vs Biaxially Oriented Polypropylene (BOPP) Infographic

materialdif.com

materialdif.com