Biaxially Oriented Polypropylene (BOPP) offers superior clarity, stiffness, and barrier properties compared to Cast Polypropylene (CPP), making it ideal for packaging applications requiring high tensile strength and crisp printability. CPP provides excellent heat sealability and flexibility, which suits it well for lamination and flow-wrap films where softness and heat resistance are critical. Selecting between BOPP and CPP depends on the balance of durability, transparency, and sealing requirements in the end-use application.

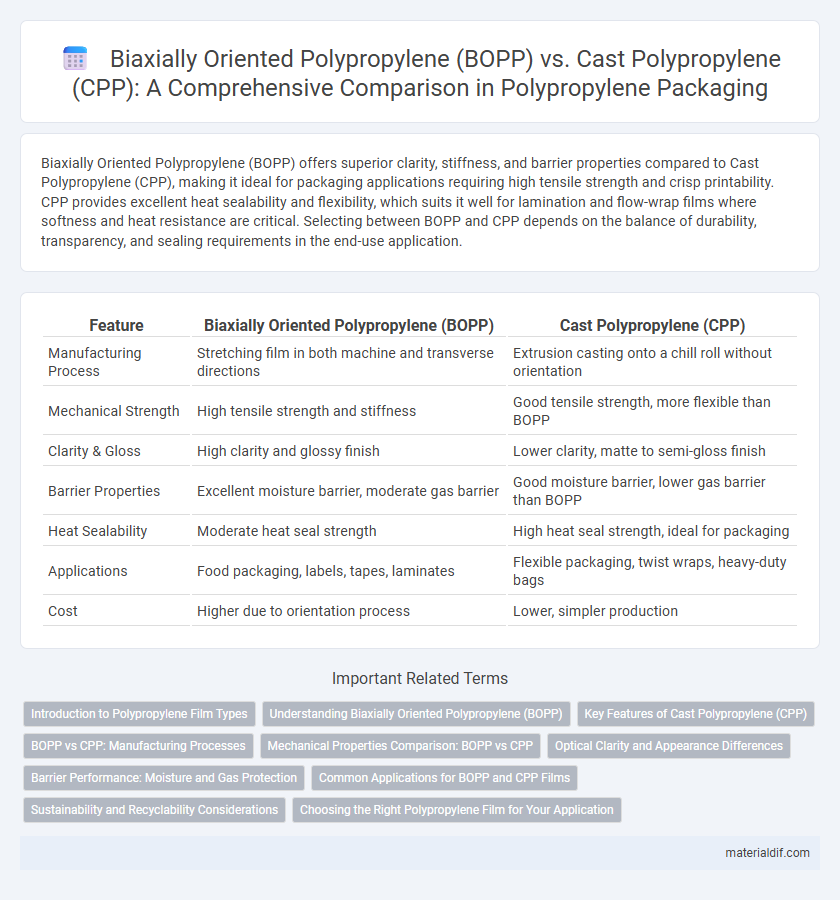

Table of Comparison

| Feature | Biaxially Oriented Polypropylene (BOPP) | Cast Polypropylene (CPP) |

|---|---|---|

| Manufacturing Process | Stretching film in both machine and transverse directions | Extrusion casting onto a chill roll without orientation |

| Mechanical Strength | High tensile strength and stiffness | Good tensile strength, more flexible than BOPP |

| Clarity & Gloss | High clarity and glossy finish | Lower clarity, matte to semi-gloss finish |

| Barrier Properties | Excellent moisture barrier, moderate gas barrier | Good moisture barrier, lower gas barrier than BOPP |

| Heat Sealability | Moderate heat seal strength | High heat seal strength, ideal for packaging |

| Applications | Food packaging, labels, tapes, laminates | Flexible packaging, twist wraps, heavy-duty bags |

| Cost | Higher due to orientation process | Lower, simpler production |

Introduction to Polypropylene Film Types

Biaxially Oriented Polypropylene (BOPP) film exhibits high tensile strength, clarity, and moisture barrier properties due to its biaxial stretching process, making it ideal for packaging and labeling applications. Cast Polypropylene (CPP) film, produced by casting molten polymer onto a chilled roller, offers superior clarity, gloss, and sealing properties but with lower tensile strength compared to BOPP. Both polypropylene film types serve distinct roles across industries, with BOPP favored for durability and printability and CPP preferred for flexible packaging requiring excellent seal integrity.

Understanding Biaxially Oriented Polypropylene (BOPP)

Biaxially Oriented Polypropylene (BOPP) is produced by stretching polypropylene film both longitudinally and transversely, resulting in enhanced tensile strength, clarity, and barrier properties compared to Cast Polypropylene (CPP). BOPP films exhibit superior stiffness, moisture resistance, and optical qualities, making them ideal for packaging applications that require durability and high printability. Its molecular orientation improves mechanical performance and dimensional stability, distinguishing BOPP from the less oriented, more flexible CPP.

Key Features of Cast Polypropylene (CPP)

Cast Polypropylene (CPP) is known for its excellent clarity, high gloss, and superior heat seal strength, making it ideal for packaging applications that require strong seals and attractive presentation. It offers good moisture barrier properties and flexibility, which enhances its performance in wrapping and laminating materials. CPP also exhibits excellent machinability and resistance to tearing, providing durability and efficiency in high-speed manufacturing processes.

BOPP vs CPP: Manufacturing Processes

Biaxially Oriented Polypropylene (BOPP) is produced through a sequential stretching process in both machine and transverse directions, enhancing tensile strength and clarity. Cast Polypropylene (CPP) is manufactured by extruding molten polymer onto a chill roll, forming a film with a more balanced thickness and higher heat resistance. The orientation in BOPP improves mechanical and barrier properties, whereas CPP's manufacturing process allows for greater flexibility and sealability in packaging applications.

Mechanical Properties Comparison: BOPP vs CPP

Biaxially Oriented Polypropylene (BOPP) exhibits superior mechanical properties compared to Cast Polypropylene (CPP), including higher tensile strength and enhanced stiffness due to its biaxial orientation process. CPP offers better elongation at break and impact resistance, making it more flexible but less rigid than BOPP. The difference in mechanical performance is primarily linked to the molecular orientation and crystallinity achieved during manufacturing, with BOPP's orientation resulting in improved dimensional stability and resistance to deformation.

Optical Clarity and Appearance Differences

Biaxially Oriented Polypropylene (BOPP) exhibits superior optical clarity and a glossy, high-quality appearance due to its stretching process, which aligns the polymer chains in two directions, enhancing transparency and brightness. In contrast, Cast Polypropylene (CPP) has a matte finish and lower clarity since it is cooled on a single drum without orientation, resulting in a thicker structure and less light transmission. These differences make BOPP ideal for packaging requiring strong visual appeal, whereas CPP serves well in applications where flexibility and heat resistance are prioritized over optical properties.

Barrier Performance: Moisture and Gas Protection

Biaxially Oriented Polypropylene (BOPP) offers superior moisture and gas barrier properties compared to Cast Polypropylene (CPP) due to its stretched film structure, which enhances molecular orientation and reduces permeability. BOPP films typically exhibit lower water vapor transmission rates (WVTR) and oxygen transmission rates (OTR), making them ideal for packaging applications requiring extended shelf life and product freshness. CPP provides moderate barrier protection but excels in heat sealability and clarity, often used where barrier performance is less critical.

Common Applications for BOPP and CPP Films

Biaxially Oriented Polypropylene (BOPP) films are widely used in food packaging, labeling, and decorative applications due to their high tensile strength, clarity, and excellent moisture barrier properties. Cast Polypropylene (CPP) films are commonly applied in lamination, snack packaging, medical packaging, and heat sealing because of their superior sealability, flexibility, and puncture resistance. Both BOPP and CPP films play crucial roles in the packaging industry, with BOPP preferred for visual appeal and CPP for functional seal performance.

Sustainability and Recyclability Considerations

Biaxially Oriented Polypropylene (BOPP) offers enhanced barrier properties and higher stiffness compared to Cast Polypropylene (CPP), contributing to improved packaging durability and reduced material usage, which supports sustainability goals. CPP, known for its superior sealability and flexibility, facilitates easier recycling processes due to its simpler film structure and lower energy consumption during processing. Both BOPP and CPP are recyclable polypropylene grades, but optimizing collection and recycling infrastructure is critical to maximizing their environmental benefits and minimizing plastic waste impact.

Choosing the Right Polypropylene Film for Your Application

Biaxially Oriented Polypropylene (BOPP) offers high tensile strength, excellent clarity, and superior barrier properties, making it ideal for packaging applications requiring durability and visual appeal. Cast Polypropylene (CPP) provides greater machine direction elongation and heat sealability, suited for applications needing flexibility and strong seals. Selecting the right polypropylene film depends on balancing the need for mechanical strength, optical properties, and processing characteristics specific to the intended use.

Biaxially Oriented Polypropylene (BOPP) vs Cast Polypropylene (CPP) Infographic

materialdif.com

materialdif.com