Homopolymer polypropylene offers higher tensile strength and clarity, making it ideal for packaging and automotive parts requiring rigidity. Copolymer polypropylene provides greater impact resistance and flexibility, suited for applications like injection molding and medical devices. Both variants excel in chemical resistance and thermal stability, but selection depends on specific performance needs and cost considerations.

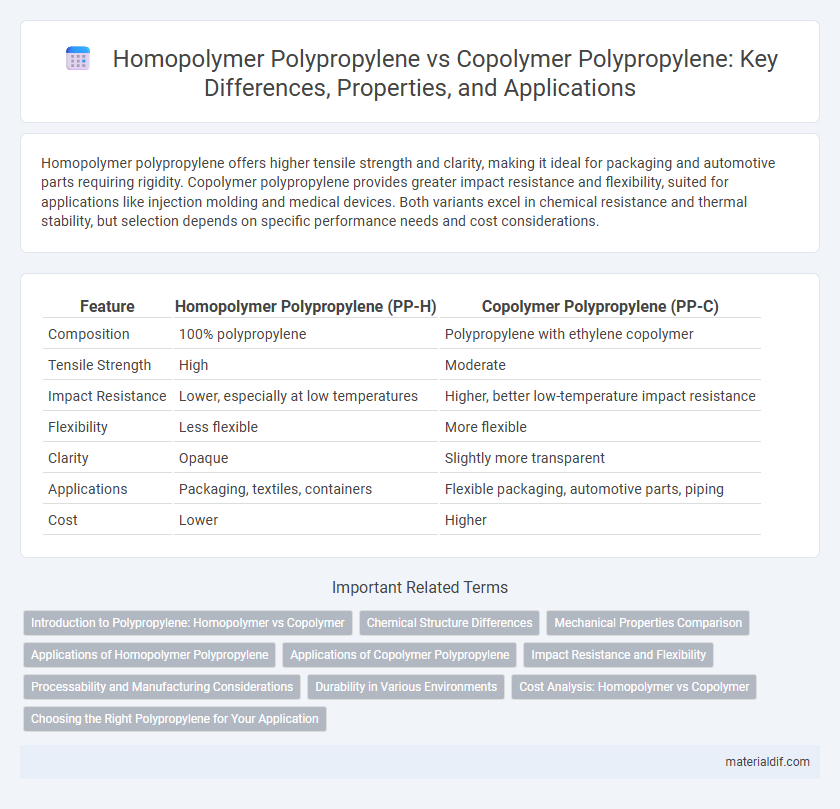

Table of Comparison

| Feature | Homopolymer Polypropylene (PP-H) | Copolymer Polypropylene (PP-C) |

|---|---|---|

| Composition | 100% polypropylene | Polypropylene with ethylene copolymer |

| Tensile Strength | High | Moderate |

| Impact Resistance | Lower, especially at low temperatures | Higher, better low-temperature impact resistance |

| Flexibility | Less flexible | More flexible |

| Clarity | Opaque | Slightly more transparent |

| Applications | Packaging, textiles, containers | Flexible packaging, automotive parts, piping |

| Cost | Lower | Higher |

Introduction to Polypropylene: Homopolymer vs Copolymer

Homopolymer polypropylene consists of a single type of propylene monomer, offering higher rigidity, tensile strength, and thermal resistance, ideal for automotive parts and packaging. Copolymer polypropylene incorporates ethylene or other monomers, providing enhanced impact resistance and flexibility, making it suitable for applications like medical devices and living hinges. The molecular structure difference between homopolymer and copolymer polypropylene directly influences their mechanical properties and processing characteristics.

Chemical Structure Differences

Homopolymer polypropylene consists solely of propylene monomers arranged in a regular, isotactic molecular structure, resulting in higher crystallinity and stiffness. Copolymer polypropylene incorporates a small amount of comonomers such as ethylene, disrupting the regularity of the polymer chain and enhancing impact resistance and flexibility. The key chemical structure difference lies in the presence of ethylene units in copolymers, which reduce crystallinity compared to the purely propylene-based homopolymers.

Mechanical Properties Comparison

Homopolymer polypropylene exhibits higher tensile strength and stiffness due to its higher crystallinity, making it ideal for applications requiring rigidity and durability. Copolymer polypropylene, which incorporates ethylene units, offers increased impact resistance and improved flexibility, enhancing performance in low-temperature environments. The mechanical properties balance between homopolymer's rigidity and copolymer's toughness dictates their selection for automotive parts, packaging, and consumer goods.

Applications of Homopolymer Polypropylene

Homopolymer polypropylene is widely used in applications requiring high stiffness and tensile strength, such as automotive parts, industrial fibers, and rigid packaging. Its crystalline structure provides excellent chemical resistance and durability, making it suitable for household goods and food containers. Compared to copolymer polypropylene, homopolymer types excel in structural applications where rigidity and heat resistance are critical.

Applications of Copolymer Polypropylene

Copolymer polypropylene is widely used in applications requiring enhanced impact resistance and flexibility, such as automotive parts, packaging films, and medical devices. Its modified molecular structure allows improved performance in low-temperature environments and better stress crack resistance compared to homopolymer polypropylene. This makes copolymer polypropylene ideal for durable containers, piping systems, and consumer goods with demanding mechanical and thermal requirements.

Impact Resistance and Flexibility

Homopolymer polypropylene exhibits higher stiffness and tensile strength but lower impact resistance and flexibility, making it suitable for rigid applications. Copolymer polypropylene, which incorporates ethylene units, enhances impact resistance and flexibility, especially at lower temperatures, due to its more amorphous structure. These differences significantly influence material selection in automotive parts, packaging, and consumer goods where durability and flexibility are critical.

Processability and Manufacturing Considerations

Homopolymer polypropylene offers higher crystallinity, resulting in greater stiffness and thermal resistance but can present challenges in extrusion and injection molding due to its higher melting point. Copolymer polypropylene contains ethylene monomers, enhancing impact resistance and flexibility, which improves flow characteristics and ease of processing in blow molding and film applications. Manufacturing considerations must balance the homopolymer's rigidity and temperature stability with the copolymer's enhanced processability and impact performance depending on the targeted product requirements.

Durability in Various Environments

Homopolymer polypropylene offers superior stiffness and chemical resistance, making it highly durable in harsh chemical environments and high-temperature applications. Copolymer polypropylene, incorporating ethylene, enhances impact resistance and flexibility, providing better performance in low-temperature and impact-prone environments. Both types exhibit excellent resistance to moisture and fatigue, but the choice depends on the specific environmental stress factors encountered.

Cost Analysis: Homopolymer vs Copolymer

Homopolymer polypropylene generally offers lower production costs due to its simpler polymerization process and higher availability of raw materials, making it a cost-effective choice for many standard applications. Copolymer polypropylene, which incorporates ethylene units, incurs higher manufacturing expenses but delivers enhanced impact resistance and flexibility, justifying its premium price in specialized uses. Cost analysis reveals homopolymer polypropylene is favored in budget-sensitive projects, while copolymer polypropylene provides added value where performance benefits outweigh increased material costs.

Choosing the Right Polypropylene for Your Application

Homopolymer polypropylene offers higher tensile strength and stiffness, making it ideal for applications requiring rigidity and clarity, such as packaging and automotive parts. Copolymer polypropylene provides enhanced impact resistance and flexibility, suitable for applications exposed to lower temperatures or requiring improved toughness, such as living hinges and medical devices. Selecting the right polypropylene depends on balancing mechanical properties with environmental conditions and end-use requirements to optimize performance and durability.

Homopolymer Polypropylene vs Copolymer Polypropylene Infographic

materialdif.com

materialdif.com