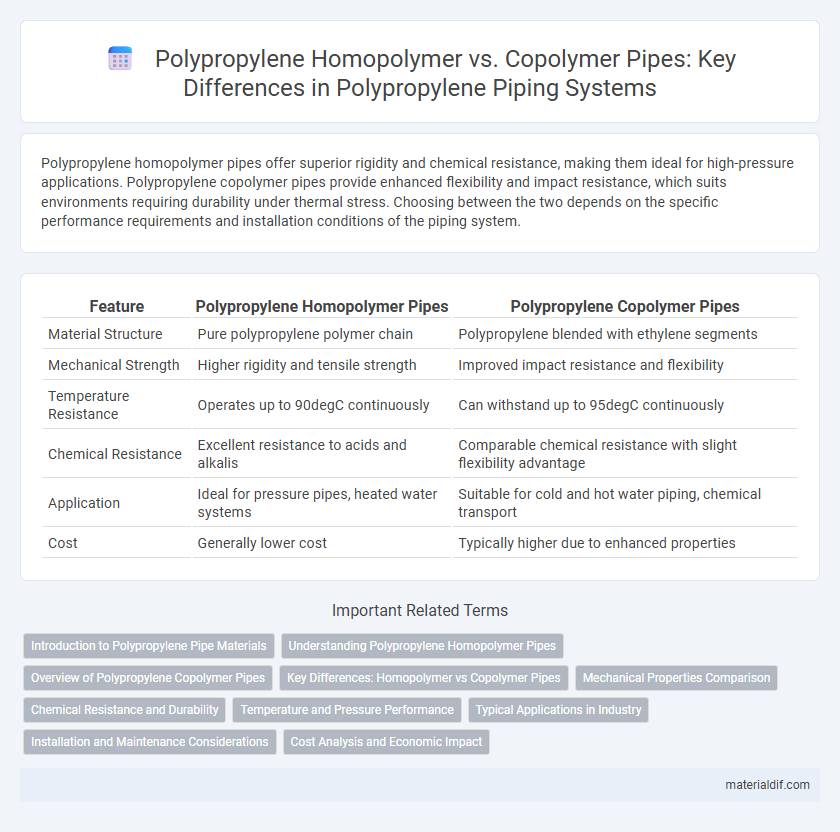

Polypropylene homopolymer pipes offer superior rigidity and chemical resistance, making them ideal for high-pressure applications. Polypropylene copolymer pipes provide enhanced flexibility and impact resistance, which suits environments requiring durability under thermal stress. Choosing between the two depends on the specific performance requirements and installation conditions of the piping system.

Table of Comparison

| Feature | Polypropylene Homopolymer Pipes | Polypropylene Copolymer Pipes |

|---|---|---|

| Material Structure | Pure polypropylene polymer chain | Polypropylene blended with ethylene segments |

| Mechanical Strength | Higher rigidity and tensile strength | Improved impact resistance and flexibility |

| Temperature Resistance | Operates up to 90degC continuously | Can withstand up to 95degC continuously |

| Chemical Resistance | Excellent resistance to acids and alkalis | Comparable chemical resistance with slight flexibility advantage |

| Application | Ideal for pressure pipes, heated water systems | Suitable for cold and hot water piping, chemical transport |

| Cost | Generally lower cost | Typically higher due to enhanced properties |

Introduction to Polypropylene Pipe Materials

Polypropylene homopolymer pipes feature high tensile strength and excellent chemical resistance, making them suitable for pressure applications. Polypropylene copolymer pipes, with their enhanced impact resistance and flexibility, are ideal for low-temperature environments and plumbing systems. Both materials exhibit excellent corrosion resistance and lightweight properties, optimizing durability and ease of installation in various piping applications.

Understanding Polypropylene Homopolymer Pipes

Polypropylene homopolymer pipes consist of a highly crystalline polymer structure, providing excellent stiffness, chemical resistance, and high temperature tolerance up to 100degC. These pipes are ideal for applications requiring durability and rigidity, such as industrial fluid transport and plumbing systems. Their superior hardness and pressure resistance differentiate them from polypropylene copolymer pipes, which offer enhanced flexibility but lower mechanical strength.

Overview of Polypropylene Copolymer Pipes

Polypropylene copolymer pipes combine the properties of both random and block copolymers, offering enhanced flexibility and impact resistance compared to polypropylene homopolymer pipes. These pipes exhibit superior performance in low-temperature applications and provide excellent chemical resistance, making them suitable for industrial and potable water systems. Their improved toughness and durability extend the service life, reducing maintenance costs and ensuring long-term reliability.

Key Differences: Homopolymer vs Copolymer Pipes

Polypropylene homopolymer pipes exhibit higher tensile strength and stiffness due to their crystalline structure, making them ideal for pressure applications. Polypropylene copolymer pipes incorporate ethylene monomers, enhancing impact resistance and flexibility, which suits them for variable temperature environments. The key difference lies in homopolymer's rigidity versus copolymer's improved toughness and thermal stability.

Mechanical Properties Comparison

Polypropylene homopolymer pipes exhibit higher tensile strength and stiffness compared to polypropylene copolymer pipes, making them more suitable for applications requiring rigidity and pressure resistance. Polypropylene copolymer pipes offer superior impact resistance and flexibility, enhancing durability under varying temperature conditions and dynamic loads. Mechanical properties such as elongation at break and impact strength highlight homopolymer's robustness, while copolymer pipes excel in toughness and resistance to crack propagation.

Chemical Resistance and Durability

Polypropylene homopolymer pipes exhibit superior chemical resistance, making them ideal for handling aggressive acids and alkalis in industrial applications. Polypropylene copolymer pipes offer enhanced durability and impact resistance due to their modified molecular structure, which improves flexibility under varying temperatures. Both types provide excellent corrosion resistance, but homopolymers excel in high-purity fluid transport while copolymers are preferred for systems requiring greater mechanical toughness.

Temperature and Pressure Performance

Polypropylene homopolymer pipes exhibit higher temperature resistance, maintaining structural integrity up to 95degC, while polypropylene copolymer pipes typically withstand temperatures up to 80degC. In terms of pressure performance, homopolymer pipes handle higher pressure ratings due to their increased crystallinity and stiffness, making them suitable for hot water and industrial applications. Copolymer pipes offer improved impact resistance and flexibility, performing better under variable pressure conditions but with lower maximum temperature tolerance.

Typical Applications in Industry

Polypropylene homopolymer pipes are highly favored in industrial applications requiring superior chemical resistance and high-temperature tolerance, such as in the chemical processing, wastewater treatment, and food processing industries. Polypropylene copolymer pipes offer enhanced impact resistance and flexibility, making them ideal for hot and cold water systems, HVAC installations, and residential plumbing. Both materials provide corrosion resistance and durability, but homopolymer variants excel in high-pressure environments, whereas copolymer types are preferred for dynamic mechanical applications.

Installation and Maintenance Considerations

Polypropylene homopolymer pipes offer higher rigidity and chemical resistance, making installation easier in environments with minimal thermal expansion, while copolymer pipes provide superior flexibility and impact resistance suitable for dynamic or fluctuating temperature applications. Maintenance of homopolymer pipes is generally lower due to their resistance to stress cracking but may require careful handling during installation to avoid brittleness. Copolymer pipes demand regular inspection for deformation or wear under mechanical stress but benefit from reduced downtime because of their resilience and adaptability to varying conditions.

Cost Analysis and Economic Impact

Polypropylene homopolymer pipes typically offer lower manufacturing costs due to their simpler polymer structure, resulting in reduced raw material expenses and energy consumption during production. Polypropylene copolymer pipes, while more expensive, provide enhanced impact resistance and flexibility, potentially lowering long-term maintenance and replacement costs in demanding applications. Evaluating the total cost of ownership reveals that homopolymer pipes are cost-effective for standard uses, whereas copolymer pipes yield better economic value in environments requiring increased durability and longevity.

Polypropylene Homopolymer Pipes vs Polypropylene Copolymer Pipes Infographic

materialdif.com

materialdif.com