Polypropylene homopolymer sheets offer higher rigidity, greater tensile strength, and better chemical resistance, making them ideal for applications requiring durability and structural integrity. Polypropylene copolymer sheets provide increased impact resistance and flexibility, suited for environments where toughness and resilience against cracking are critical. Choosing between homopolymer and copolymer sheets depends on the specific performance requirements, such as strength versus impact resistance, in industrial or packaging uses.

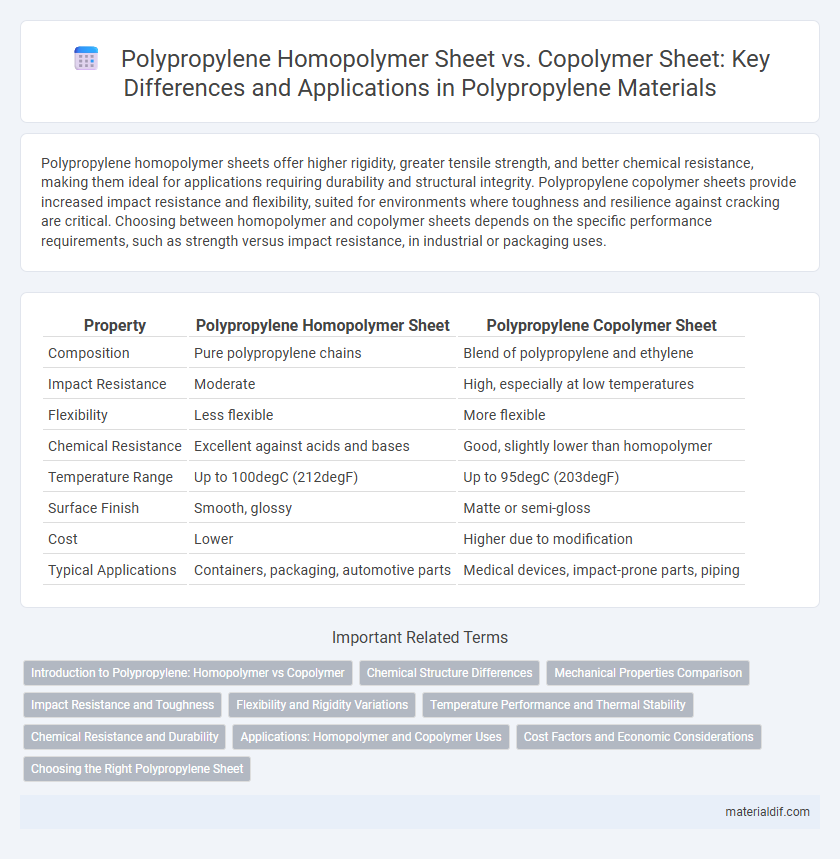

Table of Comparison

| Property | Polypropylene Homopolymer Sheet | Polypropylene Copolymer Sheet |

|---|---|---|

| Composition | Pure polypropylene chains | Blend of polypropylene and ethylene |

| Impact Resistance | Moderate | High, especially at low temperatures |

| Flexibility | Less flexible | More flexible |

| Chemical Resistance | Excellent against acids and bases | Good, slightly lower than homopolymer |

| Temperature Range | Up to 100degC (212degF) | Up to 95degC (203degF) |

| Surface Finish | Smooth, glossy | Matte or semi-gloss |

| Cost | Lower | Higher due to modification |

| Typical Applications | Containers, packaging, automotive parts | Medical devices, impact-prone parts, piping |

Introduction to Polypropylene: Homopolymer vs Copolymer

Polypropylene homopolymer sheets consist of a single type of polypropylene molecule, offering higher rigidity, higher tensile strength, and excellent fatigue resistance, making them ideal for applications requiring durability and stiffness. Polypropylene copolymer sheets blend two types of polypropylene molecules, improving impact resistance and flexibility, which enhances performance in low-temperature environments and applications demanding greater toughness. The molecular structure differences between homopolymer and copolymer sheets influence mechanical properties, chemical resistance, and suitability for varied industrial uses.

Chemical Structure Differences

Polypropylene homopolymer sheets consist of repeating units of propylene monomers in a highly regular, isotactic arrangement, resulting in a more crystalline and rigid structure. In contrast, polypropylene copolymer sheets incorporate ethylene monomers alongside propylene, creating a less regular polymer chain that improves impact resistance and flexibility. These chemical structure differences directly influence mechanical properties, with homopolymers offering higher stiffness and copolymers providing enhanced toughness.

Mechanical Properties Comparison

Polypropylene homopolymer sheets exhibit higher tensile strength and rigidity compared to copolymer sheets, making them ideal for applications requiring superior mechanical durability. Copolymer sheets demonstrate improved impact resistance and flexibility due to the incorporation of ethylene monomers within the polymer matrix. The choice between homopolymer and copolymer polypropylene sheets depends on whether enhanced stiffness or better toughness is prioritized in the intended mechanical application.

Impact Resistance and Toughness

Polypropylene homopolymer sheets offer high stiffness but exhibit lower impact resistance compared to copolymer sheets, making them suitable for applications requiring rigidity. Polypropylene copolymer sheets contain ethylene segments that enhance toughness and improve impact resistance, especially at low temperatures. Manufacturers often select copolymer sheets for products subjected to dynamic stress or harsh environmental conditions due to their superior durability.

Flexibility and Rigidity Variations

Polypropylene homopolymer sheets exhibit higher rigidity and tensile strength due to their crystalline structure, making them ideal for applications requiring stiffness and durability. In contrast, polypropylene copolymer sheets incorporate ethylene monomers, enhancing flexibility and impact resistance, which suits use cases needing better toughness and strain absorption. The choice between homopolymer and copolymer sheets depends on balancing the need for rigidity versus flexibility in industrial or consumer product designs.

Temperature Performance and Thermal Stability

Polypropylene homopolymer sheets exhibit higher thermal stability with melting points around 160-170degC, maintaining structural integrity under elevated temperatures. Polypropylene copolymer sheets, containing ethylene segments, offer improved impact resistance but lower thermal resistance, typically softening at slightly reduced temperatures near 130-150degC. The enhanced temperature performance of homopolymer sheets makes them ideal for applications requiring sustained heat exposure, whereas copolymer sheets are preferred for environments demanding better toughness and moderate thermal conditions.

Chemical Resistance and Durability

Polypropylene homopolymer sheets exhibit superior chemical resistance against acids, bases, and solvents, making them ideal for harsh industrial environments. Copolymer sheets offer enhanced durability and impact resistance due to their modified molecular structure, which allows them to withstand physical stress better. Both materials maintain excellent resistance to moisture and corrosion, but homopolymers excel in stiffness while copolymers provide greater toughness for dynamic applications.

Applications: Homopolymer and Copolymer Uses

Polypropylene homopolymer sheets offer superior rigidity and tensile strength, making them ideal for applications such as packaging, automotive parts, and consumer goods where durability is essential. Polypropylene copolymer sheets provide enhanced impact resistance and flexibility, commonly used in medical devices, chemical tanks, and food containers requiring better stress crack resistance. Both materials cater to different industry needs based on mechanical properties and environmental exposure.

Cost Factors and Economic Considerations

Polypropylene homopolymer sheets generally cost less due to simpler polymerization processes and higher production yield, making them economically favorable for applications requiring rigidity and chemical resistance. In contrast, polypropylene copolymer sheets feature enhanced impact strength and flexibility but involve more complex manufacturing steps, increasing material and processing costs. Businesses must weigh higher upfront expenses of copolymer sheets against their longer-term durability and reduced replacement frequency.

Choosing the Right Polypropylene Sheet

Polypropylene homopolymer sheets offer higher tensile strength and rigidity, making them ideal for applications requiring durability and stiffness. Polypropylene copolymer sheets provide greater impact resistance and flexibility, suitable for environments with low temperatures or repeated stress. Selecting the right polypropylene sheet depends on balancing strength requirements with impact resistance for specific industrial or packaging uses.

Polypropylene Homopolymer Sheet vs Polypropylene Copolymer Sheet Infographic

materialdif.com

materialdif.com