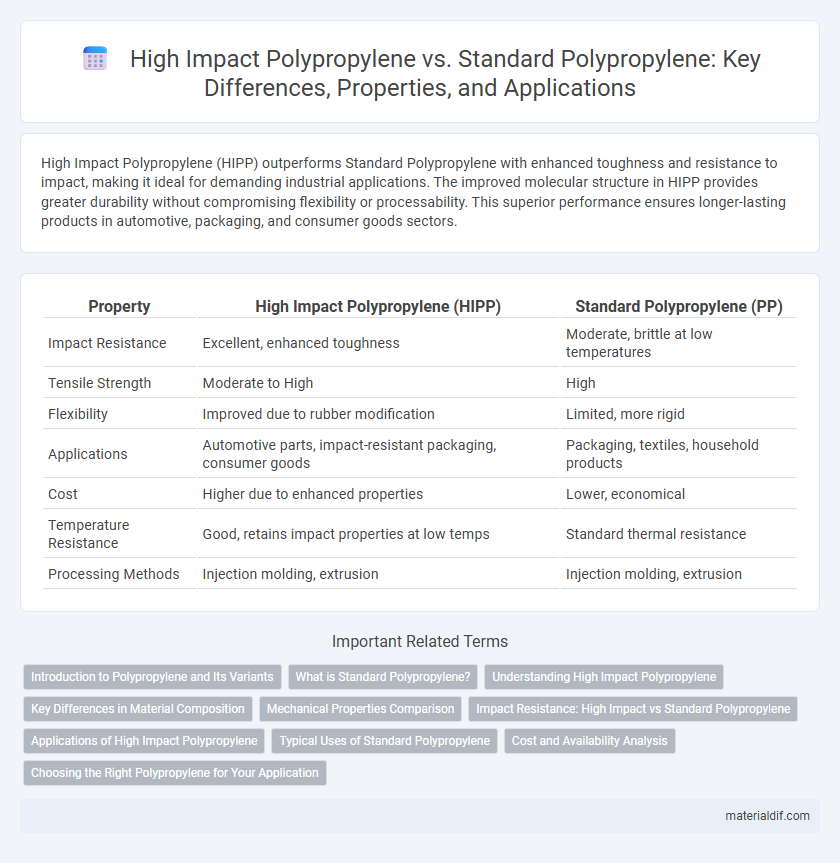

High Impact Polypropylene (HIPP) outperforms Standard Polypropylene with enhanced toughness and resistance to impact, making it ideal for demanding industrial applications. The improved molecular structure in HIPP provides greater durability without compromising flexibility or processability. This superior performance ensures longer-lasting products in automotive, packaging, and consumer goods sectors.

Table of Comparison

| Property | High Impact Polypropylene (HIPP) | Standard Polypropylene (PP) |

|---|---|---|

| Impact Resistance | Excellent, enhanced toughness | Moderate, brittle at low temperatures |

| Tensile Strength | Moderate to High | High |

| Flexibility | Improved due to rubber modification | Limited, more rigid |

| Applications | Automotive parts, impact-resistant packaging, consumer goods | Packaging, textiles, household products |

| Cost | Higher due to enhanced properties | Lower, economical |

| Temperature Resistance | Good, retains impact properties at low temps | Standard thermal resistance |

| Processing Methods | Injection molding, extrusion | Injection molding, extrusion |

Introduction to Polypropylene and Its Variants

Polypropylene is a versatile thermoplastic polymer widely used in packaging, automotive parts, and consumer goods due to its durability and chemical resistance. High Impact Polypropylene (HIPP) differs from Standard Polypropylene by incorporating rubber modifiers, enhancing its toughness and impact resistance, making it suitable for applications requiring greater mechanical strength. Standard Polypropylene offers excellent rigidity and transparency but is more brittle, while HIPP balances strength and flexibility for demanding environments.

What is Standard Polypropylene?

Standard Polypropylene (PP) is a versatile thermoplastic polymer widely used in packaging, automotive parts, and consumer goods due to its excellent chemical resistance, low density, and good mechanical properties. It offers high tensile strength and flexibility but has relatively low impact resistance compared to High Impact Polypropylene (HIPP). Standard PP is commonly chosen for applications where rigidity and cost-effectiveness are prioritized over enhanced toughness.

Understanding High Impact Polypropylene

High Impact Polypropylene (HIPP) is a modified form of standard polypropylene designed to enhance toughness and resistance to impact. By incorporating elastomeric additives or copolymers, HIPP achieves improved mechanical properties, making it suitable for applications requiring durability under stress. Standard polypropylene, while cost-effective and versatile, lacks the enhanced impact strength characteristic of High Impact Polypropylene.

Key Differences in Material Composition

High Impact Polypropylene (HIPP) incorporates elastomers such as ethylene-propylene rubber, enhancing its toughness and resistance to impact compared to Standard Polypropylene. Standard Polypropylene typically consists of isotactic polypropylene with a crystalline structure that offers rigidity but lower impact strength. The key difference in material composition lies in HIPP's rubber-modified polymer matrix, which improves flexibility and impact resistance while maintaining polypropylene's inherent chemical and thermal properties.

Mechanical Properties Comparison

High Impact Polypropylene (HIPP) offers significantly improved impact resistance compared to Standard Polypropylene (PP), making it ideal for applications requiring enhanced toughness under sudden stress. The tensile strength of HIPP closely matches that of standard PP, but its elongation at break and impact strength are substantially higher, providing superior durability in dynamic environments. This combination of mechanical properties enables HIPP to withstand higher levels of mechanical shock without deformation or failure, whereas standard PP may crack or break under similar conditions.

Impact Resistance: High Impact vs Standard Polypropylene

High Impact Polypropylene (HIPP) offers significantly enhanced impact resistance compared to Standard Polypropylene due to the incorporation of elastomeric modifiers that improve toughness and reduce brittleness. This material delivers superior performance in applications where durability under mechanical stress and resistance to cracking or breaking upon impact are critical. Standard Polypropylene, while cost-effective and versatile, lacks this enhanced toughness, making it more susceptible to damage in high-impact environments.

Applications of High Impact Polypropylene

High Impact Polypropylene (HIPP) is widely used in automotive parts, consumer goods, and packaging due to its enhanced toughness and resistance to impact compared to standard polypropylene. It is ideal for manufacturing automotive bumpers, protective helmets, and durable containers, where mechanical stress and impact resistance are critical. The material's improved impact strength extends the lifespan and performance of everyday products exposed to rough handling or dynamic loads.

Typical Uses of Standard Polypropylene

Standard polypropylene is widely used in packaging, automotive parts, and consumer goods due to its excellent chemical resistance, low density, and good fatigue resistance. It is ideal for applications such as containers, pipes, and household appliances where toughness and rigidity are required but high impact strength is not critical. Common examples include bottle caps, food storage containers, and cable insulation.

Cost and Availability Analysis

High Impact Polypropylene (HIPP) typically incurs higher production costs due to the incorporation of elastomers that enhance its toughness, resulting in a price premium compared to Standard Polypropylene (PP). Availability of HIPP may be more limited as its specialized formulations require specific manufacturing processes and raw materials, whereas Standard PP is widely produced and readily accessible across global markets. Cost-effectiveness and bulk procurement favor Standard Polypropylene in large-scale applications, while HIPP's enhanced mechanical properties justify its higher cost in impact-sensitive uses.

Choosing the Right Polypropylene for Your Application

High Impact Polypropylene (HIPP) offers enhanced toughness and resistance to impact compared to Standard Polypropylene, making it ideal for applications requiring durability under stress, such as automotive parts and protective packaging. Standard Polypropylene provides excellent chemical resistance and stiffness, suited for less demanding uses like packaging films and consumer goods. Selecting between HIPP and Standard Polypropylene depends on the specific mechanical properties and environmental conditions your application demands.

High Impact Polypropylene vs Standard Polypropylene Infographic

materialdif.com

materialdif.com