Flame retardant polypropylene (PP) incorporates specialized additives that significantly enhance its resistance to ignition and slow down the spread of fire, making it ideal for applications requiring strict fire safety standards. Non-flame retardant polypropylene lacks these additives, which results in higher flammability and limits its use in environments prone to heat or fire exposure. Choosing flame retardant PP improves overall safety and compliance in industries such as automotive, electronics, and construction.

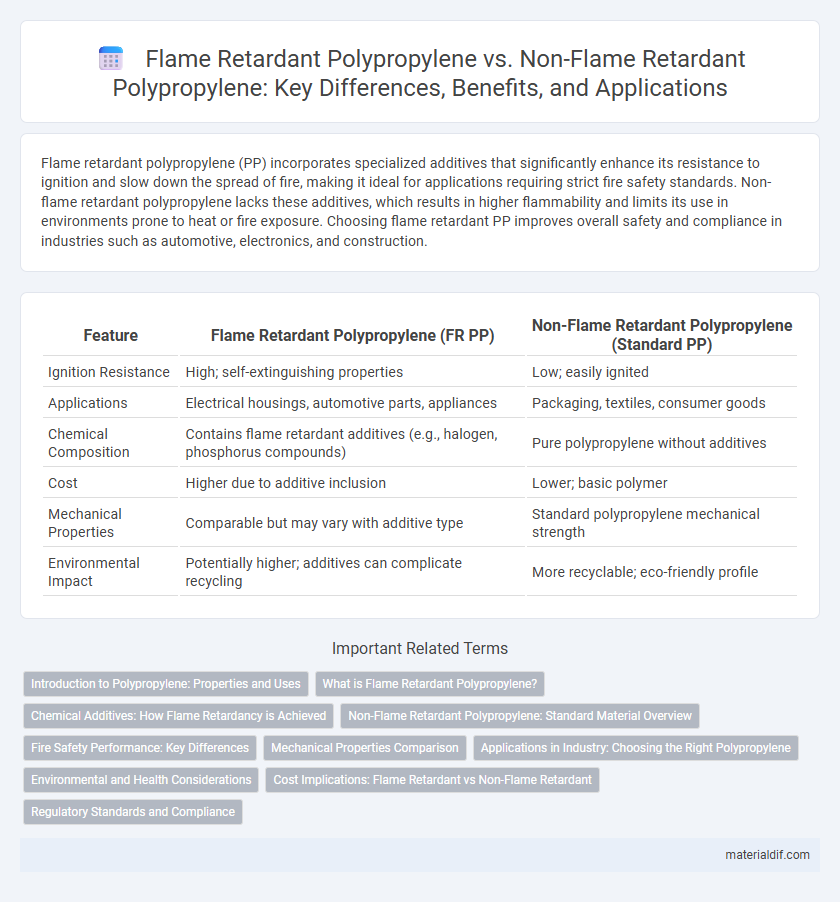

Table of Comparison

| Feature | Flame Retardant Polypropylene (FR PP) | Non-Flame Retardant Polypropylene (Standard PP) |

|---|---|---|

| Ignition Resistance | High; self-extinguishing properties | Low; easily ignited |

| Applications | Electrical housings, automotive parts, appliances | Packaging, textiles, consumer goods |

| Chemical Composition | Contains flame retardant additives (e.g., halogen, phosphorus compounds) | Pure polypropylene without additives |

| Cost | Higher due to additive inclusion | Lower; basic polymer |

| Mechanical Properties | Comparable but may vary with additive type | Standard polypropylene mechanical strength |

| Environmental Impact | Potentially higher; additives can complicate recycling | More recyclable; eco-friendly profile |

Introduction to Polypropylene: Properties and Uses

Flame retardant polypropylene is enhanced with additives that significantly improve its resistance to ignition and slow down the spread of fire, making it ideal for applications requiring higher safety standards such as electrical housings and automotive parts. Non-flame retardant polypropylene maintains its inherent properties like lightweight, chemical resistance, and high tensile strength, commonly used in packaging, textiles, and consumer goods. Understanding the fundamental properties of polypropylene, including its versatility and durability, helps determine suitability for specific applications where fire safety regulations vary.

What is Flame Retardant Polypropylene?

Flame retardant polypropylene is a modified form of polypropylene infused with chemical additives that inhibit or resist the spread of fire, enhancing its safety in various applications. These additives work by interfering with the combustion process, reducing flammability and slowing down heat release. This makes flame retardant polypropylene ideal for use in electrical components, automotive parts, and building materials where fire resistance is critical.

Chemical Additives: How Flame Retardancy is Achieved

Flame retardant polypropylene is chemically enhanced with additives such as halogenated compounds, phosphorus-based agents, and metal hydroxides like aluminum trihydrate to inhibit ignition and slow flame spread. These additives work by promoting char formation, releasing flame-inhibiting gases, and absorbing heat during combustion, significantly improving fire resistance. Non-flame retardant polypropylene lacks these chemical modifications, making it more susceptible to rapid burning and higher heat release rates.

Non-Flame Retardant Polypropylene: Standard Material Overview

Non-flame retardant polypropylene is a widely used thermoplastic polymer known for its excellent chemical resistance, low density, and high impact strength. It is typically utilized in applications where fire resistance is not critical, such as packaging, automotive parts, and consumer goods. This standard material offers cost-effective performance with good processability and electrical insulation properties but lacks the enhanced safety features provided by flame retardant additives.

Fire Safety Performance: Key Differences

Flame retardant polypropylene is engineered with additives that enhance its resistance to ignition and slow down combustion, significantly improving fire safety performance compared to non-flame retardant polypropylene. Non-flame retardant polypropylene ignites more easily and burns rapidly, posing higher fire risk in applications requiring stringent safety standards. The incorporation of flame retardant agents in polypropylene materials reduces smoke generation and toxic gas emissions during fire, providing critical advantages in fire hazard mitigation.

Mechanical Properties Comparison

Flame retardant polypropylene exhibits reduced tensile strength and impact resistance compared to non-flame retardant polypropylene due to the incorporation of flame retardant additives that can affect the polymer matrix's integrity. Non-flame retardant polypropylene maintains higher elongation at break and better flexibility, making it more suitable for applications requiring mechanical durability. The trade-off between flame resistance and mechanical performance is critical in selecting polypropylene grades for specific industrial uses.

Applications in Industry: Choosing the Right Polypropylene

Flame retardant polypropylene is essential in industries like electrical, automotive, and construction where fire safety standards are stringent, providing enhanced resistance to ignition and slowing flame spread. Non-flame retardant polypropylene is preferred in packaging, consumer goods, and textiles where flexibility, cost-effectiveness, and chemical resistance are prioritized over fire retardancy. Selecting the right polypropylene depends on balancing regulatory compliance, application-specific fire safety requirements, and performance characteristics such as durability and thermal stability.

Environmental and Health Considerations

Flame retardant polypropylene contains additives that can release toxic chemicals such as brominated flame retardants during combustion, posing environmental and health risks through persistent organic pollutants and potential bioaccumulation. Non-flame retardant polypropylene avoids these toxic emissions but is more flammable, increasing fire hazards and potential injuries. Selecting polypropylene materials requires balancing fire safety with the ecological impact of chemical additives and human exposure risks.

Cost Implications: Flame Retardant vs Non-Flame Retardant

Flame retardant polypropylene typically incurs higher material and processing costs due to the incorporation of specialized additives that enhance fire resistance. Non-flame retardant polypropylene is generally more cost-effective but lacks the safety benefits required for applications demanding stringent fire safety standards. Manufacturers must balance these cost implications against regulatory requirements and end-use performance when selecting between flame retardant and non-flame retardant polypropylene.

Regulatory Standards and Compliance

Flame retardant polypropylene is engineered to meet stringent regulatory standards such as UL 94 and IEC 60695, ensuring enhanced fire resistance for applications requiring compliance with safety codes. Non-flame retardant polypropylene lacks these additives and generally does not pass fire safety certifications, limiting its use in regulated industries like automotive, electronics, and construction. Compliance with these standards is critical for manufacturers to avoid penalties and ensure product safety in markets with strict fire hazard regulations.

Flame Retardant Polypropylene vs Non-Flame Retardant Polypropylene Infographic

materialdif.com

materialdif.com