Metallocene-catalyzed polypropylene (PP) offers superior control over polymer architecture, resulting in enhanced clarity, impact resistance, and consistent mechanical properties compared to Ziegler-Natta catalyzed PP. The uniform active sites in metallocene catalysts produce isotactic polymers with narrow molecular weight distribution, improving processability and end-use performance. Ziegler-Natta catalysts, while cost-effective, generate broader molecular weight distributions and less uniform stereoregularity, which can limit polypropylene's potential in applications requiring precision and clarity.

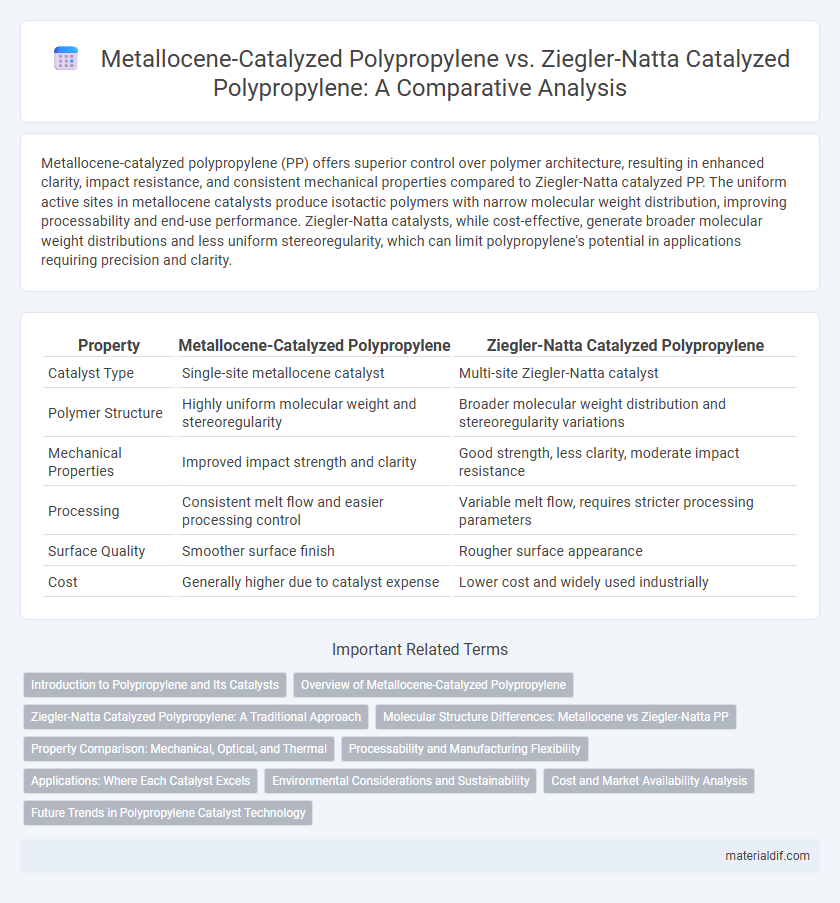

Table of Comparison

| Property | Metallocene-Catalyzed Polypropylene | Ziegler-Natta Catalyzed Polypropylene |

|---|---|---|

| Catalyst Type | Single-site metallocene catalyst | Multi-site Ziegler-Natta catalyst |

| Polymer Structure | Highly uniform molecular weight and stereoregularity | Broader molecular weight distribution and stereoregularity variations |

| Mechanical Properties | Improved impact strength and clarity | Good strength, less clarity, moderate impact resistance |

| Processing | Consistent melt flow and easier processing control | Variable melt flow, requires stricter processing parameters |

| Surface Quality | Smoother surface finish | Rougher surface appearance |

| Cost | Generally higher due to catalyst expense | Lower cost and widely used industrially |

Introduction to Polypropylene and Its Catalysts

Polypropylene production primarily utilizes metallocene and Ziegler-Natta catalysts, each influencing polymer properties and performance. Metallocene-catalyzed polypropylene offers uniform molecular weight distribution and enhanced clarity due to single-site catalyst precision. Ziegler-Natta catalysts deliver cost-effective production with broader molecular weight distribution, impacting impact resistance and processability.

Overview of Metallocene-Catalyzed Polypropylene

Metallocene-catalyzed polypropylene (PP) offers superior molecular weight distribution and enhanced stereoregularity compared to Ziegler-Natta catalyzed PP, resulting in improved mechanical properties and transparency. The metallocene catalyst system enables precise control over polymer architecture, allowing for the production of tailor-made polypropylene grades with consistent performance. This catalytic technology also facilitates higher catalyst efficiency and reduced production of by-products, contributing to more sustainable polymer manufacturing.

Ziegler-Natta Catalyzed Polypropylene: A Traditional Approach

Ziegler-Natta catalyzed polypropylene remains a cornerstone in the plastics industry due to its cost-effectiveness and well-established large-scale production processes. This traditional catalytic system enables the synthesis of isotactic polypropylene with high crystallinity and excellent mechanical properties, suitable for applications ranging from packaging to automotive components. Despite the emergence of metallocene catalysts, Ziegler-Natta catalysts continue to dominate the market, supported by decades of process optimization and vast industrial infrastructure.

Molecular Structure Differences: Metallocene vs Ziegler-Natta PP

Metallocene-catalyzed polypropylene exhibits a more uniform molecular structure with narrow molecular weight distribution and precise stereoregularity, resulting in enhanced clarity and mechanical properties. In contrast, Ziegler-Natta catalyzed polypropylene has a broader molecular weight distribution with heterogeneous stereochemical arrangement, affecting its crystallinity and impact resistance. The controlled polymerization of metallocene catalysts enables consistent isotacticity and reduced chain defects compared to the traditional Ziegler-Natta process.

Property Comparison: Mechanical, Optical, and Thermal

Metallocene-catalyzed polypropylene exhibits superior mechanical properties, including higher tensile strength and improved impact resistance, compared to Ziegler-Natta catalyzed PP, attributed to its more uniform molecular weight distribution and stereoregularity. Optical properties of metallocene PP show enhanced clarity and lower haze due to narrower polymer chain distributions and fewer defects. Thermally, metallocene polypropylene demonstrates higher melting points and better thermal stability, resulting from its more consistent molecular architecture and optimized crystallinity.

Processability and Manufacturing Flexibility

Metallocene-catalyzed polypropylene (PP) offers superior processability due to its uniform molecular weight distribution and enhanced stereoregularity, resulting in consistent melt flow and improved product quality. In contrast, Ziegler-Natta catalyzed PP exhibits broader molecular weight distribution, leading to variable processing performance but offers cost advantages in large-scale manufacturing. Metallocene catalysts enable greater manufacturing flexibility with customizable polymer properties for specialized applications, while Ziegler-Natta systems remain favored for high-volume, cost-sensitive production.

Applications: Where Each Catalyst Excels

Metallocene-catalyzed polypropylene (PP) offers superior clarity, flexibility, and precise control over polymer architecture, making it ideal for packaging films, medical devices, and automotive interiors requiring enhanced cosmetic appeal and performance. Ziegler-Natta catalyzed PP excels in applications demanding high stiffness, impact resistance, and cost efficiency, such as injection-molded automotive parts, appliances, and rigid packaging. The distinct catalytic mechanisms result in polymers with tailored isotacticity and molecular weight distribution, directly influencing their suitability for specific industrial uses.

Environmental Considerations and Sustainability

Metallocene-catalyzed polypropylene (PP) offers improved molecular uniformity and enhanced recyclability compared to Ziegler-Natta catalyzed PP, contributing to more efficient waste management and reduced environmental impact. Ziegler-Natta catalyzed PP production often involves higher energy consumption and generates more volatile organic compounds (VOCs), whereas metallocene catalysts enable lower temperature polymerization processes, reducing greenhouse gas emissions. The precision of metallocene catalysts supports the development of PP with tailored degradation rates and improved compatibility with recycling systems, advancing sustainability in plastic manufacturing.

Cost and Market Availability Analysis

Metallocene-catalyzed polypropylene offers superior uniformity and enhanced material properties but incurs higher production costs due to expensive catalyst systems and complex manufacturing processes. Ziegler-Natta catalyzed polypropylene dominates market availability, benefiting from well-established production infrastructure and lower catalyst expenses, making it more cost-effective for large-scale applications. The cost-performance balance positions Ziegler-Natta PP as the preferred choice in commodity markets, while metallocene PP targets high-performance niches despite limited volume supply.

Future Trends in Polypropylene Catalyst Technology

Metallocene-catalyzed polypropylene (PP) offers enhanced control over polymer architecture, resulting in improved mechanical properties and clarity compared to traditional Ziegler-Natta catalyzed PP. Future trends focus on hybrid catalyst systems combining metallocene precision with Ziegler-Natta scalability to achieve higher productivity and novel polymer functionalities. Advances in catalyst design aim to optimize stereoregularity and molecular weight distribution, driving innovation in lightweight automotive parts and sustainable packaging solutions.

Metallocene-Catalyzed PP vs Ziegler-Natta Catalyzed PP Infographic

materialdif.com

materialdif.com