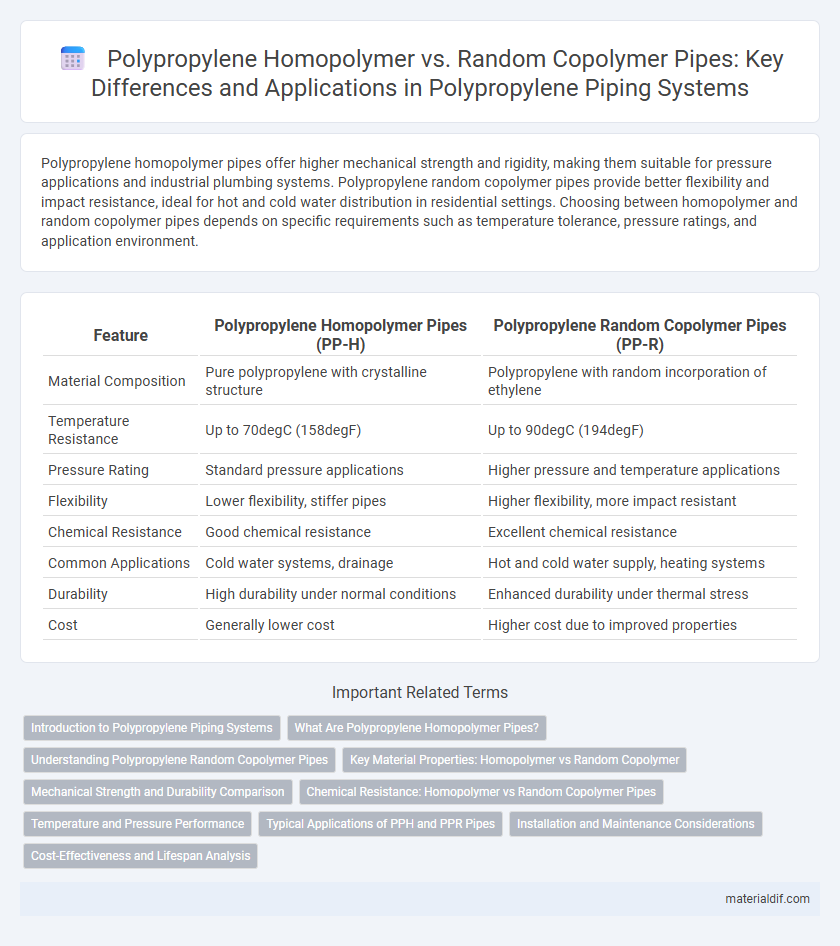

Polypropylene homopolymer pipes offer higher mechanical strength and rigidity, making them suitable for pressure applications and industrial plumbing systems. Polypropylene random copolymer pipes provide better flexibility and impact resistance, ideal for hot and cold water distribution in residential settings. Choosing between homopolymer and random copolymer pipes depends on specific requirements such as temperature tolerance, pressure ratings, and application environment.

Table of Comparison

| Feature | Polypropylene Homopolymer Pipes (PP-H) | Polypropylene Random Copolymer Pipes (PP-R) |

|---|---|---|

| Material Composition | Pure polypropylene with crystalline structure | Polypropylene with random incorporation of ethylene |

| Temperature Resistance | Up to 70degC (158degF) | Up to 90degC (194degF) |

| Pressure Rating | Standard pressure applications | Higher pressure and temperature applications |

| Flexibility | Lower flexibility, stiffer pipes | Higher flexibility, more impact resistant |

| Chemical Resistance | Good chemical resistance | Excellent chemical resistance |

| Common Applications | Cold water systems, drainage | Hot and cold water supply, heating systems |

| Durability | High durability under normal conditions | Enhanced durability under thermal stress |

| Cost | Generally lower cost | Higher cost due to improved properties |

Introduction to Polypropylene Piping Systems

Polypropylene homopolymer pipes feature a crystalline structure that offers excellent chemical resistance and high-temperature tolerance, making them ideal for industrial piping systems. Polypropylene random copolymer pipes exhibit enhanced flexibility and impact strength due to their amorphous molecular arrangement, suited for both hot and cold water applications. Both types contribute to durable, corrosion-resistant polypropylene piping systems widely used in plumbing, heating, and chemical transport industries.

What Are Polypropylene Homopolymer Pipes?

Polypropylene homopolymer pipes consist of a single type of propylene monomer, offering a high level of rigidity and superior chemical resistance ideal for industrial applications and hot water systems. These pipes exhibit excellent tensile strength and dimensional stability, making them suitable for pressure piping systems where durability and resistance to stress cracking are critical. Compared to random copolymer pipes, homopolymers provide enhanced stiffness but lower impact resistance and flexibility.

Understanding Polypropylene Random Copolymer Pipes

Polypropylene Random Copolymer (PPR) pipes offer enhanced flexibility and higher resistance to stress cracking compared to Polypropylene Homopolymer pipes, making them ideal for both hot and cold water applications. Their random molecular structure improves impact strength and temperature tolerance, ensuring long-term durability in plumbing and industrial systems. PPR pipes also exhibit superior chemical resistance, enabling safe transport of aggressive fluids without degradation over time.

Key Material Properties: Homopolymer vs Random Copolymer

Polypropylene homopolymer pipes exhibit higher tensile strength and superior chemical resistance, making them ideal for industrial applications requiring durability and rigidity. Polypropylene random copolymer pipes offer enhanced impact resistance and flexibility at low temperatures due to their modified polymer structure. The choice between these materials depends on specific application requirements such as temperature tolerance, mechanical stress, and environmental exposure.

Mechanical Strength and Durability Comparison

Polypropylene Homopolymer (PPH) pipes exhibit higher mechanical strength due to their crystalline molecular structure, making them ideal for high-pressure applications. In contrast, Polypropylene Random Copolymer (PPR) pipes offer enhanced durability and flexibility, resisting cracking and impact better under varying temperatures. PPH pipes are preferred for rigid, load-bearing installations, while PPR pipes excel in systems requiring thermal and chemical resistance along with long-term durability.

Chemical Resistance: Homopolymer vs Random Copolymer Pipes

Polypropylene homopolymer pipes offer superior chemical resistance to concentrated acids and alkalis, making them ideal for aggressive chemical transport. Polypropylene random copolymer pipes provide enhanced flexibility and improved resistance to stress cracking, suitable for applications involving dilute chemicals and varying temperatures. The choice between homopolymer and random copolymer pipes depends on the specific chemical exposure and mechanical stress requirements of the installation.

Temperature and Pressure Performance

Polypropylene homopolymer pipes exhibit higher temperature resistance, typically withstanding continuous operating temperatures up to 95degC, making them suitable for hot water applications and high-pressure systems. In contrast, polypropylene random copolymer pipes generally have better impact resistance at lower temperatures but a slightly lower maximum continuous service temperature around 70degC. Both materials maintain excellent chemical resistance and pressure ratings, but homopolymer pipes are preferred in environments demanding superior thermal and pressure performance.

Typical Applications of PPH and PPR Pipes

Polypropylene homopolymer (PPH) pipes are predominantly used in industrial applications requiring high chemical resistance and temperature stability, such as chemical processing and corrosion-resistant piping systems. Polypropylene random copolymer (PPR) pipes excel in plumbing and residential water supply due to their enhanced flexibility, impact resistance, and suitability for hot and cold water distribution. The distinct molecular structures of PPH and PPR dictate their optimal performance environments, with PPH favored for aggressive media transport and PPR preferred for domestic and commercial piping systems.

Installation and Maintenance Considerations

Polypropylene Homopolymer pipes offer superior stiffness and chemical resistance, making installation easier in high-stress environments, while Polypropylene Random Copolymer pipes provide greater flexibility, which facilitates bending and fitting in complex layouts. Homopolymer pipes require careful support spacing to prevent sagging, whereas random copolymer pipes' flexibility reduces the need for frequent supports but may demand more specialized joining techniques. Maintenance of homopolymer pipes is generally straightforward due to their rigidity and resistance to creep, whereas random copolymer pipes benefit from enhanced crack resistance, reducing long-term repair needs in dynamic applications.

Cost-Effectiveness and Lifespan Analysis

Polypropylene Homopolymer (PPH) pipes offer higher crystallinity, resulting in superior stiffness and chemical resistance, which contributes to a longer lifespan in high-temperature applications compared to Polypropylene Random Copolymer (PPR) pipes. PPR pipes, characterized by greater flexibility and impact resistance due to their random copolymer structure, generally incur lower initial costs but may require more frequent replacements in aggressive environments. Analyzing cost-effectiveness, PPH pipes demonstrate better long-term value through durability and reduced maintenance, while PPR pipes provide an economical solution for lower-stress conditions with shorter service life expectations.

Polypropylene Homopolymer Pipes vs Polypropylene Random Copolymer Pipes Infographic

materialdif.com

materialdif.com