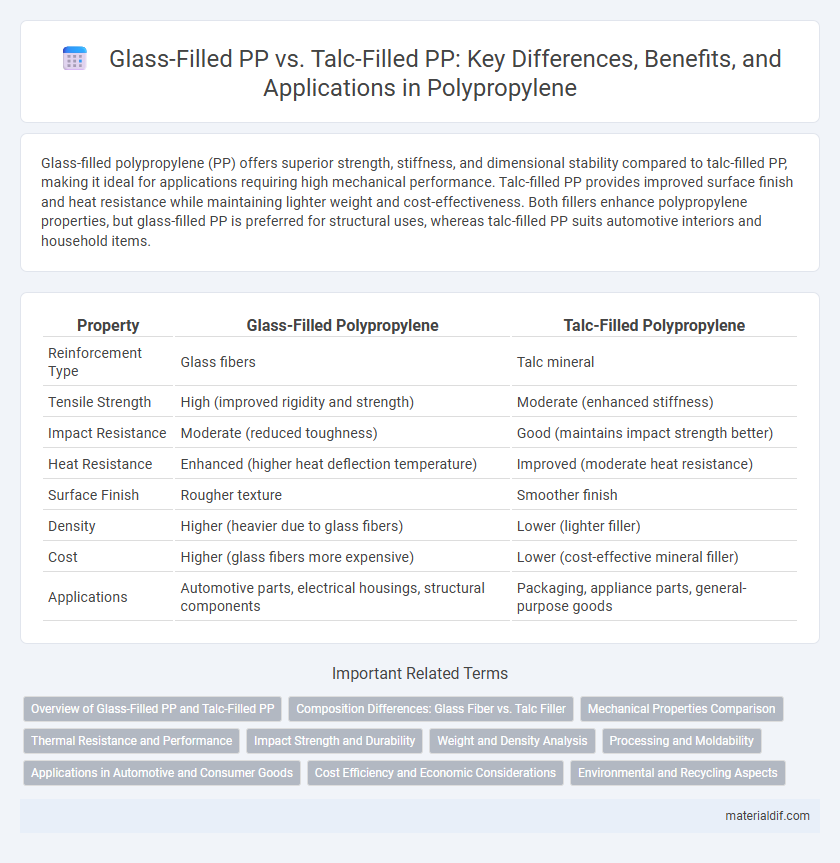

Glass-filled polypropylene (PP) offers superior strength, stiffness, and dimensional stability compared to talc-filled PP, making it ideal for applications requiring high mechanical performance. Talc-filled PP provides improved surface finish and heat resistance while maintaining lighter weight and cost-effectiveness. Both fillers enhance polypropylene properties, but glass-filled PP is preferred for structural uses, whereas talc-filled PP suits automotive interiors and household items.

Table of Comparison

| Property | Glass-Filled Polypropylene | Talc-Filled Polypropylene |

|---|---|---|

| Reinforcement Type | Glass fibers | Talc mineral |

| Tensile Strength | High (improved rigidity and strength) | Moderate (enhanced stiffness) |

| Impact Resistance | Moderate (reduced toughness) | Good (maintains impact strength better) |

| Heat Resistance | Enhanced (higher heat deflection temperature) | Improved (moderate heat resistance) |

| Surface Finish | Rougher texture | Smoother finish |

| Density | Higher (heavier due to glass fibers) | Lower (lighter filler) |

| Cost | Higher (glass fibers more expensive) | Lower (cost-effective mineral filler) |

| Applications | Automotive parts, electrical housings, structural components | Packaging, appliance parts, general-purpose goods |

Overview of Glass-Filled PP and Talc-Filled PP

Glass-filled polypropylene (PP) incorporates glass fibers to enhance strength, stiffness, and thermal stability, making it ideal for automotive and industrial applications requiring durable materials. Talc-filled PP contains talc minerals that improve rigidity, heat resistance, and dimensional stability while maintaining good surface finish and processability. Both materials offer tailored mechanical properties for specific uses, with glass-filled PP favoring structural reinforcement and talc-filled PP optimizing lightweight, heat-resistant components.

Composition Differences: Glass Fiber vs. Talc Filler

Glass-filled polypropylene (PP) contains reinforcing glass fibers, typically ranging from 10% to 40% by weight, which significantly enhance tensile strength, rigidity, and impact resistance. Talc-filled polypropylene uses finely ground talc mineral as a filler, usually between 5% and 30%, improving stiffness and heat resistance while maintaining better surface finish and dimensional stability. The key composition difference is that glass fibers provide structural reinforcement with higher mechanical performance, whereas talc filler primarily modifies thermal and dimensional properties without substantially increasing strength.

Mechanical Properties Comparison

Glass-filled polypropylene (PP) offers significantly higher tensile strength and impact resistance compared to talc-filled PP, making it ideal for applications requiring enhanced durability and structural integrity. Talc-filled PP provides improved stiffness and heat distortion resistance but generally exhibits lower impact toughness and elongation at break than glass-filled variants. The choice between glass-filled and talc-filled PP depends on balancing mechanical performance needs with cost considerations and specific application requirements.

Thermal Resistance and Performance

Glass-filled polypropylene offers superior thermal resistance and mechanical strength compared to talc-filled PP, making it ideal for applications requiring high heat deflection temperatures up to 140degC. Talc-filled polypropylene provides enhanced dimensional stability and improved stiffness while maintaining moderate thermal resistance typically around 110degC. Selection between glass-filled and talc-filled PP depends on the balance between thermal performance and structural requirements for specific industrial uses.

Impact Strength and Durability

Glass-filled polypropylene offers superior impact strength and enhanced durability due to the reinforcement provided by glass fibers, making it ideal for applications requiring high mechanical performance. Talc-filled polypropylene, while improving stiffness and heat resistance, typically exhibits lower impact strength compared to glass-filled variants, resulting in moderate durability under dynamic stress. Selection between glass-filled and talc-filled PP depends on balancing the need for impact resistance with dimensional stability and thermal properties in the intended application.

Weight and Density Analysis

Glass-filled polypropylene typically exhibits higher density, around 1.20 to 1.35 g/cm3, compared to talc-filled polypropylene, which ranges from 1.10 to 1.25 g/cm3, resulting in greater overall weight for glass-filled PP parts. The increased density in glass-filled PP is attributed to the high modulus and specific gravity of glass fibers, enhancing stiffness but adding weight. Talc-filled PP offers a lower weight solution with moderate density, providing balanced mechanical properties while maintaining reduced mass for applications sensitive to weight constraints.

Processing and Moldability

Glass-filled polypropylene offers enhanced stiffness and dimensional stability but requires higher processing temperatures and specialized mold designs to accommodate its abrasive nature and prevent wear. Talc-filled polypropylene provides improved flow properties and easier moldability with lower processing temperatures, enabling shorter cycle times and more intricate part geometries. Molders often balance the choice between glass and talc fillers based on the need for mechanical strength versus processing efficiency and surface finish quality.

Applications in Automotive and Consumer Goods

Glass-filled polypropylene (PP) offers superior strength and stiffness, making it ideal for automotive components such as battery cases, under-the-hood parts, and structural elements requiring high mechanical performance. Talc-filled PP provides enhanced dimensional stability and surface finish, preferred for consumer goods like appliance housings and interior automotive trim panels where aesthetic appeal and thermal resistance are crucial. Both composites optimize polypropylene properties, enabling manufacturers to tailor materials for specific applications within automotive and consumer product sectors.

Cost Efficiency and Economic Considerations

Glass-filled polypropylene offers higher strength and rigidity, making it ideal for structural applications, but it comes with increased material and processing costs compared to talc-filled PP. Talc-filled polypropylene provides a cost-effective alternative with improved stiffness and dimensional stability at a lower price point, benefiting mass production and budget-sensitive projects. Selecting between glass-filled and talc-filled PP requires balancing performance needs against economic constraints to optimize overall cost efficiency.

Environmental and Recycling Aspects

Glass-filled polypropylene (PP) generally poses greater environmental challenges than talc-filled PP due to the higher energy consumption and difficulty in recycling associated with glass fibers. Talc-filled PP offers improved recyclability and lower ecological impact because talc is an abundant, inert mineral that does not degrade recycling processes or increase energy requirements significantly. Both materials require proper sorting to optimize recycling efficiency, but talc-filled PP aligns better with circular economy goals given its reduced environmental footprint.

Glass-Filled PP vs Talc-Filled PP Infographic

materialdif.com

materialdif.com