Monomeric polypropylene consists of individual monomer units that have not yet undergone polymerization, resulting in a simpler chemical structure with limited mechanical properties. Polymeric polypropylene is formed through the polymerization process, linking monomers into long chains that provide enhanced strength, durability, and thermal resistance. The polymeric form dominates industrial applications due to its superior performance in manufacturing polypropylene PET products.

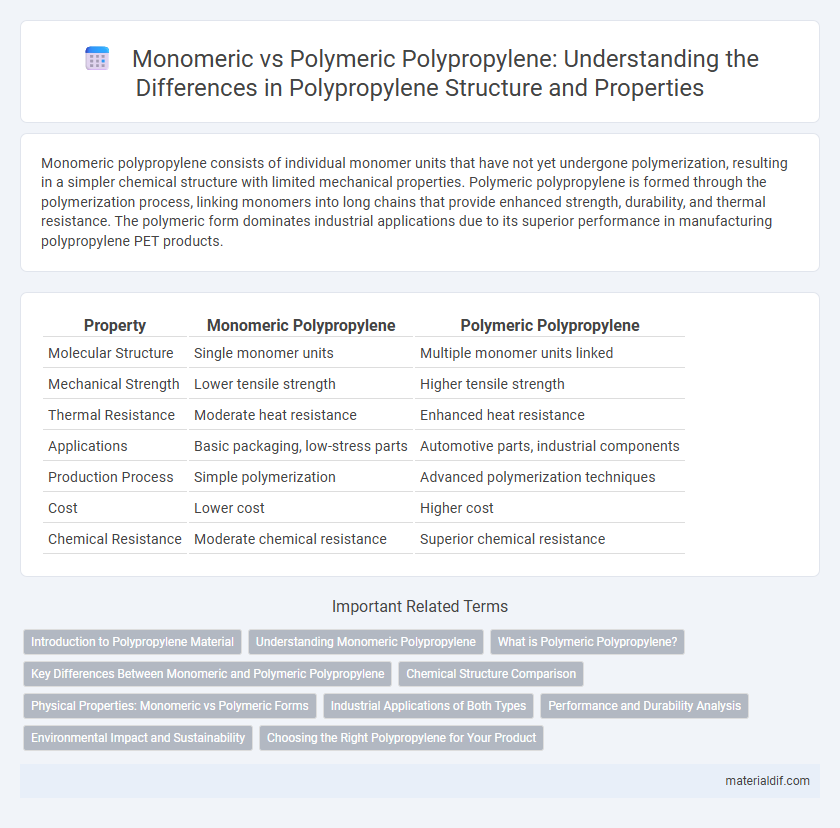

Table of Comparison

| Property | Monomeric Polypropylene | Polymeric Polypropylene |

|---|---|---|

| Molecular Structure | Single monomer units | Multiple monomer units linked |

| Mechanical Strength | Lower tensile strength | Higher tensile strength |

| Thermal Resistance | Moderate heat resistance | Enhanced heat resistance |

| Applications | Basic packaging, low-stress parts | Automotive parts, industrial components |

| Production Process | Simple polymerization | Advanced polymerization techniques |

| Cost | Lower cost | Higher cost |

| Chemical Resistance | Moderate chemical resistance | Superior chemical resistance |

Introduction to Polypropylene Material

Monomeric polypropylene is derived directly from the polymerization of propylene monomers, resulting in a versatile thermoplastic with excellent chemical resistance and mechanical properties. Polymeric polypropylene refers to the final polymer chains formed by the repeated linking of propylene monomers, exhibiting high tensile strength, thermal stability, and impact resistance. Understanding the distinction between monomeric and polymeric polypropylene is crucial for applications in packaging, automotive components, and textiles where material performance is critical.

Understanding Monomeric Polypropylene

Monomeric polypropylene refers to the homopolymer made from propylene monomers, characterized by its isotactic sequence which provides high crystallinity and mechanical strength. Unlike polymeric polypropylene blends, monomeric polypropylene offers superior chemical resistance and thermal stability due to its uniform molecular structure. This form is widely used in automotive components, packaging, and textiles where durability and performance under stress are critical.

What is Polymeric Polypropylene?

Polymeric polypropylene is a polymer composed of long chains of propylene monomers linked together through a polymerization process, resulting in a high molecular weight material with enhanced mechanical properties. Unlike monomeric polypropylene, which refers to the individual propylene units, polymeric polypropylene exhibits increased tensile strength, chemical resistance, and thermal stability, making it suitable for diverse applications in packaging, automotive parts, and textiles. The polymer's structure can be tailored through isotactic, syndiotactic, or atactic configurations, influencing crystallinity and performance characteristics.

Key Differences Between Monomeric and Polymeric Polypropylene

Monomeric polypropylene consists of individual propylene units not chemically bonded into long chains, resulting in lower molecular weight and reduced mechanical strength. Polymeric polypropylene features long chains of propylene monomers chemically bonded through polymerization, providing enhanced tensile strength, heat resistance, and durability. Key differences include molecular structure, thermal properties, and application performance, where polymeric polypropylene dominates industrial use due to its superior material characteristics.

Chemical Structure Comparison

Monomeric polypropylene consists of propylene units isolated as single molecules, while polymeric polypropylene is formed by the polymerization of propylene monomers into long chains. The chemical structure of polymeric polypropylene features repetitive C3H6 units linked through covalent bonds, creating a high molecular weight material with distinct isotactic, syndiotactic, or atactic configurations. These stereochemical variations in polymeric polypropylene influence its crystallinity, melting point, and mechanical properties, setting it apart from monomeric forms.

Physical Properties: Monomeric vs Polymeric Forms

Monomeric polypropylene, primarily composed of individual propylene units, exhibits lower molecular weight resulting in reduced tensile strength and flexibility compared to polymeric polypropylene. Polymeric polypropylene consists of long chains of propylene monomers, which enhance crystallinity, thermal resistance, and impact strength. Differences in molecular architecture directly influence melting point, stiffness, and chemical resistance between monomeric and polymeric polypropylene.

Industrial Applications of Both Types

Monomeric polypropylene, derived from the polymerization of a single type of monomer, is predominantly used in packaging, automotive parts, and consumer goods due to its high stiffness and heat resistance. Polymeric polypropylene, which involves copolymerization with various monomers, offers enhanced impact strength and flexibility, making it suitable for applications such as medical devices, textiles, and flexible packaging. Industrial sectors leverage monomeric types for structural components and polymeric variants for products requiring improved durability and elasticity.

Performance and Durability Analysis

Monomeric polypropylene, produced from a single monomer unit, typically exhibits lower molecular weight and reduced mechanical strength compared to polymeric polypropylene, which consists of longer polymer chains. Polymeric polypropylene demonstrates enhanced durability, superior resistance to chemical and thermal degradation, and improved impact strength, making it suitable for high-performance applications. Performance analysis reveals that polymeric polypropylene offers better fatigue resistance and dimensional stability under stress, essential for automotive and industrial uses.

Environmental Impact and Sustainability

Monomeric polypropylene, derived directly from propylene monomers, typically requires less energy and emits fewer greenhouse gases during production compared to polymeric polypropylene, which involves additional polymerization steps. Polymeric polypropylene offers enhanced durability and recyclability, contributing to longer product life cycles and reduced environmental waste when managed effectively. Sustainable practices in production and recycling of polymeric polypropylene significantly mitigate ecological footprints, aligning with circular economy goals.

Choosing the Right Polypropylene for Your Product

Monomeric polypropylene, typically used in simpler applications, offers consistent properties and cost-effectiveness, making it ideal for standard packaging and consumer goods. Polymeric polypropylene presents enhanced molecular weight distribution and improved mechanical strength, suitable for high-performance products requiring durability and impact resistance. Selecting the right polypropylene depends on balancing factors like processing method, environmental stress resistance, and end-use functional requirements.

Monomeric Polypropylene vs Polymeric Polypropylene Infographic

materialdif.com

materialdif.com