Polypropylene Random Copolymer (PPRC) offers superior clarity compared to Polypropylene Homopolymer (PPH), making it ideal for applications requiring transparent packaging or containers. PPRC's molecular structure reduces crystallinity, which enhances its optical properties and produces a clearer, more aesthetically appealing finish. In contrast, PPH has a higher level of crystallinity, resulting in opacity and a more rigid appearance, suitable for products where transparency is not essential.

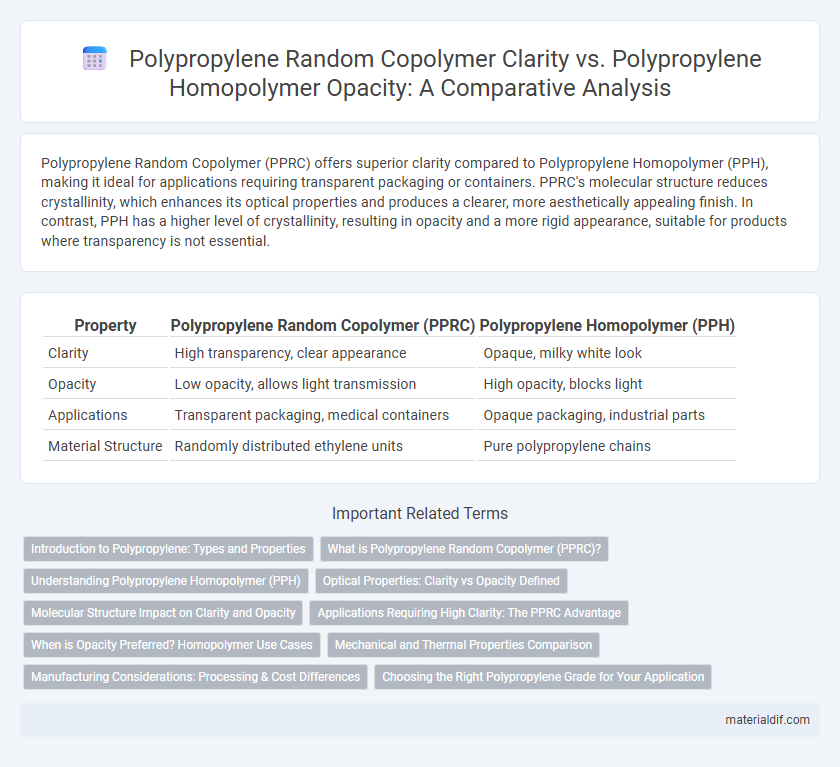

Table of Comparison

| Property | Polypropylene Random Copolymer (PPRC) | Polypropylene Homopolymer (PPH) |

|---|---|---|

| Clarity | High transparency, clear appearance | Opaque, milky white look |

| Opacity | Low opacity, allows light transmission | High opacity, blocks light |

| Applications | Transparent packaging, medical containers | Opaque packaging, industrial parts |

| Material Structure | Randomly distributed ethylene units | Pure polypropylene chains |

Introduction to Polypropylene: Types and Properties

Polypropylene Random Copolymer (PPRC) offers superior clarity compared to Polypropylene Homopolymer (PPH) due to its amorphous structure, which reduces crystallinity and enhances light transmission. PPH exhibits higher opacity as a result of its highly crystalline nature, making it more rigid but less transparent. These distinct optical properties influence the selection of polypropylene types for applications requiring either clarity or strength.

What is Polypropylene Random Copolymer (PPRC)?

Polypropylene Random Copolymer (PPRC) is a type of polypropylene made by incorporating ethylene molecules randomly into the polypropylene chain, resulting in improved clarity and flexibility compared to Polypropylene Homopolymer. PPRC exhibits a translucent appearance due to its amorphous regions, making it ideal for applications requiring aesthetic transparency such as packaging and containers. The random ethylene distribution reduces crystallinity, enhancing impact resistance and optical properties relative to the more opaque and crystalline Polypropylene Homopolymer.

Understanding Polypropylene Homopolymer (PPH)

Polypropylene Homopolymer (PPH) is characterized by a highly crystalline structure, which results in its typical opacity and higher rigidity compared to Polypropylene Random Copolymer (PPRC). The increased crystallinity in PPH enhances mechanical strength and chemical resistance but reduces transparency, making it suitable for applications where durability is prioritized over clarity. Understanding these structural differences is essential for selecting the appropriate polypropylene type based on the desired balance between strength and optical properties.

Optical Properties: Clarity vs Opacity Defined

Polypropylene Random Copolymer (PPRC) exhibits superior clarity due to its lower crystallinity, allowing more light to pass through and resulting in transparent or translucent appearances. In contrast, Polypropylene Homopolymer (PPH) demonstrates higher opacity because its densely packed crystalline structure scatters light, producing a more solid, opaque look. Optical properties such as haze, gloss, and light transmission rates clearly differentiate PPRC's clarity from PPH's opacity in applications like packaging and medical devices.

Molecular Structure Impact on Clarity and Opacity

Polypropylene random copolymer (PPRC) exhibits enhanced clarity compared to polypropylene homopolymer (PPH) due to its unique molecular structure, which incorporates ethylene units randomly distributed along the polypropylene chain, disrupting crystallinity and reducing light scattering. In contrast, the highly regular, isotactic molecular arrangement of PPH results in a dense crystalline structure that increases opacity by intensifying light diffraction. This difference in crystallinity, influenced by the molecular architecture, directly impacts transparency, making PPRC ideal for applications requiring visual clarity while PPH is favored for structural components needing opacity and rigidity.

Applications Requiring High Clarity: The PPRC Advantage

Polypropylene Random Copolymer (PPRC) offers superior clarity compared to Polypropylene Homopolymer (PPH), making it ideal for applications requiring transparent or aesthetically pleasing packaging such as food containers and medical devices. The amorphous structure of PPRC reduces opacity and enhances light transmission, which is critical for consumer visibility and product appeal. This clarity advantage allows manufacturers to meet stringent standards in industries where product inspection and attractiveness are paramount.

When is Opacity Preferred? Homopolymer Use Cases

Polypropylene homopolymer is preferred when high opacity is essential, providing superior light-blocking properties compared to polypropylene random copolymer. This makes homopolymer ideal for packaging applications that require UV protection, such as food containers and pharmaceutical packaging, to preserve product integrity. Its rigidity and chemical resistance further enhance durability in demanding environments.

Mechanical and Thermal Properties Comparison

Polypropylene Random Copolymer (PPRC) exhibits superior clarity compared to Polypropylene Homopolymer (PPH), attributed to its amorphous structure that enhances light transmission. Mechanically, PPH typically offers higher stiffness and tensile strength due to its crystalline nature, while PPRC provides better impact resistance and flexibility, benefiting applications requiring durability under stress. Thermally, PPH withstands higher melting points around 160-170degC, whereas PPRC demonstrates improved performance at lower temperatures with enhanced resistance to stress cracking.

Manufacturing Considerations: Processing & Cost Differences

Polypropylene Random Copolymer (PPRC) offers superior clarity due to its amorphous structure, making it ideal for applications demanding transparency, whereas Polypropylene Homopolymer (PPH) exhibits higher opacity from its crystalline nature. Manufacturing PPRC requires more precise polymerization techniques that increase processing complexity and costs compared to the simpler, more cost-efficient production of PPH. The increased cost of PPRC is offset by its value in high-clarity products, while PPH remains preferred for applications prioritizing strength and thermal resistance.

Choosing the Right Polypropylene Grade for Your Application

Polypropylene random copolymer offers superior clarity compared to polypropylene homopolymer, which is typically more opaque due to its higher crystallinity. This difference in optical properties makes random copolymer ideal for applications requiring transparency, such as food packaging and medical containers. Selecting the right polypropylene grade depends on the desired balance between visual appeal and mechanical strength, with random copolymer favored for clear, impact-resistant products and homopolymer suited for more rigid, opaque applications.

Polypropylene Random Copolymer Clarity vs Polypropylene Homopolymer Opacity Infographic

materialdif.com

materialdif.com