Polypropylene glass-filled offers superior mechanical strength and higher stiffness compared to polypropylene talc-filled, making it ideal for demanding structural applications. Polypropylene talc-filled provides better dimensional stability and improved heat resistance while maintaining lighter weight and enhanced surface finish. Selecting between glass-filled and talc-filled polypropylene depends on specific requirements such as load-bearing capacity, thermal performance, and aesthetic considerations.

Table of Comparison

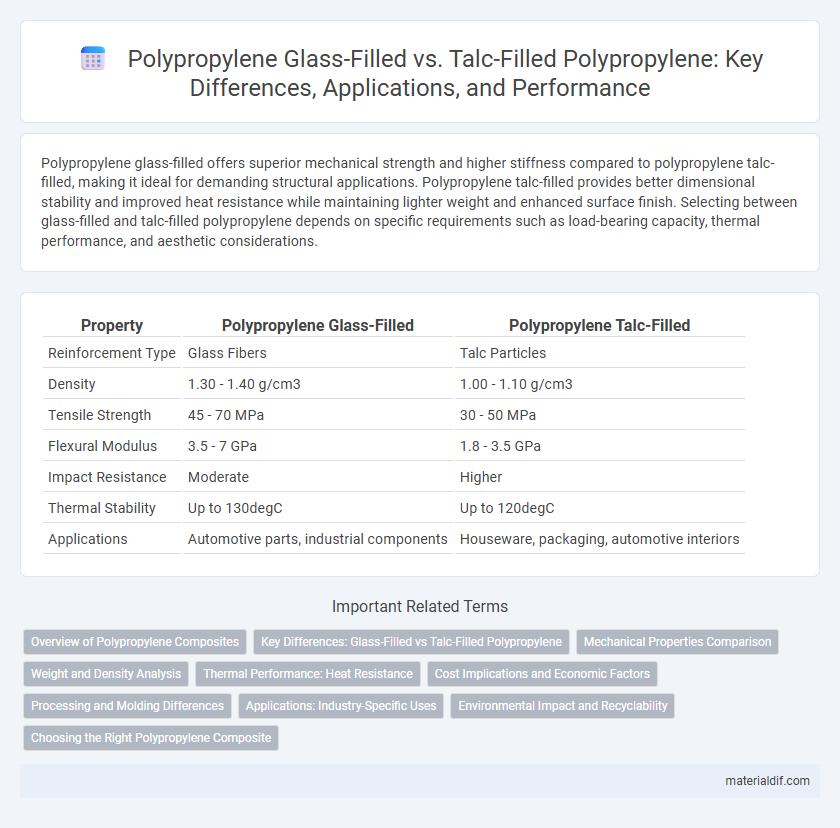

| Property | Polypropylene Glass-Filled | Polypropylene Talc-Filled |

|---|---|---|

| Reinforcement Type | Glass Fibers | Talc Particles |

| Density | 1.30 - 1.40 g/cm3 | 1.00 - 1.10 g/cm3 |

| Tensile Strength | 45 - 70 MPa | 30 - 50 MPa |

| Flexural Modulus | 3.5 - 7 GPa | 1.8 - 3.5 GPa |

| Impact Resistance | Moderate | Higher |

| Thermal Stability | Up to 130degC | Up to 120degC |

| Applications | Automotive parts, industrial components | Houseware, packaging, automotive interiors |

Overview of Polypropylene Composites

Polypropylene composites are enhanced by the addition of fillers such as glass fibers and talc to improve mechanical properties. Glass-filled polypropylene offers superior strength, stiffness, and impact resistance due to the high modulus of glass fibers. Talc-filled polypropylene improves dimensional stability, heat resistance, and surface finish, making it ideal for automotive and consumer goods applications.

Key Differences: Glass-Filled vs Talc-Filled Polypropylene

Glass-filled polypropylene offers higher tensile strength and improved dimensional stability compared to talc-filled polypropylene, making it ideal for automotive and industrial applications requiring durability. Talc-filled polypropylene enhances stiffness and heat resistance while maintaining better surface finish and impact resistance, suitable for consumer goods and household appliances. The choice between glass-filled and talc-filled polypropylene depends on balancing mechanical strength, thermal performance, weight considerations, and aesthetic requirements.

Mechanical Properties Comparison

Polypropylene glass-filled composites exhibit higher tensile strength and stiffness compared to talc-filled polypropylene due to the superior reinforcement provided by glass fibers. Talc-filled polypropylene offers improved dimensional stability and heat resistance but generally has lower impact strength and elongation at break than glass-filled variants. These differences make glass-filled polypropylene ideal for load-bearing applications, while talc-filled polypropylene suits components requiring thermal stability and rigidity.

Weight and Density Analysis

Polypropylene glass-filled composites exhibit higher density, typically around 1.3-1.5 g/cm3, due to the inclusion of glass fibers, which also increases weight compared to talc-filled variants. Talc-filled polypropylene, with densities ranging from 0.95 to 1.2 g/cm3, offers a lighter alternative while enhancing stiffness and thermal stability. The choice between glass-filled and talc-filled polypropylene impacts component weight and mechanical properties, critical in automotive and industrial applications requiring optimized strength-to-weight ratios.

Thermal Performance: Heat Resistance

Polypropylene glass-filled exhibits superior thermal performance with heat resistance typically up to 120-130degC, making it ideal for applications requiring enhanced mechanical strength at elevated temperatures. In contrast, polypropylene talc-filled generally withstands heat up to 100-110degC, offering improved dimensional stability but lower heat resistance compared to glass-filled variants. The selection between polypropylene glass-filled and talc-filled materials largely depends on the specific thermal requirements and mechanical properties needed for the end-use environment.

Cost Implications and Economic Factors

Polypropylene glass-filled materials typically present higher costs due to the expense of glass fibers and enhanced mechanical properties, making them preferable for applications requiring superior strength and stiffness. In contrast, polypropylene talc-filled variants offer a cost-effective solution with lower filler prices and improved dimensional stability, suitable for less demanding structural needs. Economic factors favor talc-filled polypropylene in large-volume, cost-sensitive production, while glass-filled polypropylene justifies its premium in performance-critical, high-value products.

Processing and Molding Differences

Polypropylene glass-filled composites exhibit higher stiffness and tensile strength, requiring elevated processing temperatures and more precise mold temperature control during injection molding to prevent fiber degradation. In contrast, polypropylene talc-filled grades allow for easier processing with lower melt viscosity and improved flowability, enabling faster cycle times and reduced injection pressures. Mold design for glass-filled polypropylene often necessitates robust tooling to handle fiber abrasion, whereas talc-filled polypropylene molds benefit from smoother cavity surfaces to minimize surface defects.

Applications: Industry-Specific Uses

Polypropylene glass-filled is commonly used in automotive and electrical industries due to its enhanced strength, stiffness, and heat resistance, making it ideal for under-the-hood components and electrical housings. Polypropylene talc-filled offers improved rigidity and dimensional stability, frequently applied in consumer goods, packaging, and household appliances where surface finish and cost efficiency are critical. The choice between these fillers depends on industry-specific requirements such as mechanical performance, thermal resistance, and aesthetic demands.

Environmental Impact and Recyclability

Polypropylene glass-filled composites offer enhanced strength but pose greater challenges in recycling due to the difficulty of separating glass fibers, which can lead to more complex waste management and increased environmental impact. Talc-filled polypropylene is generally easier to recycle and has a lower environmental footprint because talc is a mineral additive that does not significantly hinder the polypropylene recycling process. Choosing talc-filled polypropylene improves material circularity and sustainability by facilitating more efficient recycling and reducing landfill accumulation.

Choosing the Right Polypropylene Composite

Polypropylene glass-filled composites offer superior mechanical strength, stiffness, and thermal resistance, making them ideal for demanding automotive and industrial applications requiring high structural integrity. Polypropylene talc-filled composites provide enhanced dimensional stability, improved surface finish, and better processability, suitable for consumer goods and parts needing a balance of strength and cosmetic appeal. Selecting the right polypropylene composite depends on application-specific needs such as load-bearing capacity, thermal performance, and aesthetic requirements.

Polypropylene Glass-Filled vs Polypropylene Talc-Filled Infographic

materialdif.com

materialdif.com