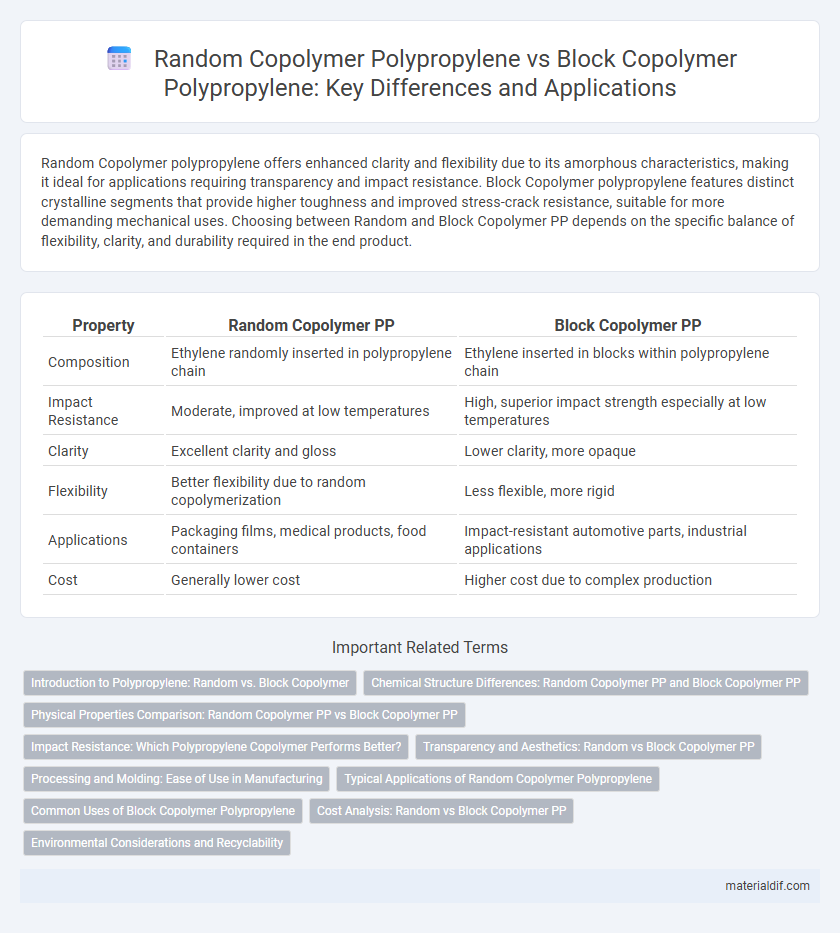

Random Copolymer polypropylene offers enhanced clarity and flexibility due to its amorphous characteristics, making it ideal for applications requiring transparency and impact resistance. Block Copolymer polypropylene features distinct crystalline segments that provide higher toughness and improved stress-crack resistance, suitable for more demanding mechanical uses. Choosing between Random and Block Copolymer PP depends on the specific balance of flexibility, clarity, and durability required in the end product.

Table of Comparison

| Property | Random Copolymer PP | Block Copolymer PP |

|---|---|---|

| Composition | Ethylene randomly inserted in polypropylene chain | Ethylene inserted in blocks within polypropylene chain |

| Impact Resistance | Moderate, improved at low temperatures | High, superior impact strength especially at low temperatures |

| Clarity | Excellent clarity and gloss | Lower clarity, more opaque |

| Flexibility | Better flexibility due to random copolymerization | Less flexible, more rigid |

| Applications | Packaging films, medical products, food containers | Impact-resistant automotive parts, industrial applications |

| Cost | Generally lower cost | Higher cost due to complex production |

Introduction to Polypropylene: Random vs. Block Copolymer

Random copolymer polypropylene (PP) incorporates ethylene units uniformly distributed along the polymer chain, enhancing clarity, flexibility, and impact resistance at low temperatures. Block copolymer PP features distinct segments of polypropylene and ethylene-propylene, delivering superior toughness and improved stress-crack resistance ideal for rigid applications. These structural variations influence mechanical properties, thermal stability, and processing methods in packaging, automotive parts, and consumer goods.

Chemical Structure Differences: Random Copolymer PP and Block Copolymer PP

Random copolymer polypropylene (PP) consists of propylene units with ethylene randomly incorporated along the polymer chain, resulting in a less crystalline structure and improved clarity. Block copolymer PP features distinct blocks of propylene and ethylene sequences, creating segmented regions that enhance impact resistance and flexibility. These chemical structure differences influence the thermal, mechanical, and optical properties critical for targeted applications.

Physical Properties Comparison: Random Copolymer PP vs Block Copolymer PP

Random copolymer polypropylene exhibits superior clarity and flexibility due to the uniform distribution of comonomer units, resulting in lower crystallinity and enhanced impact resistance at low temperatures. Block copolymer polypropylene features distinct crystalline and amorphous phases offering higher toughness and improved impact strength, especially under stress, but lower optical clarity compared to random copolymers. The choice between random and block copolymer PP depends on balancing mechanical properties such as stiffness, impact resistance, and transparency for specific application requirements.

Impact Resistance: Which Polypropylene Copolymer Performs Better?

Random copolymer polypropylene offers improved clarity and flexibility but has lower impact resistance compared to block copolymer polypropylene, which incorporates a higher ethylene content in distinct block sequences. Block copolymer PP exhibits superior impact resistance, especially at low temperatures, due to its enhanced ability to absorb and dissipate energy under stress. This makes block copolymer polypropylene the preferred choice for applications requiring toughness and durability.

Transparency and Aesthetics: Random vs Block Copolymer PP

Random copolymer polypropylene exhibits superior transparency and clarity due to its more amorphous structure, allowing better light transmission compared to block copolymer polypropylene. Block copolymer PP contains ethylene sequences that enhance impact resistance but increase crystallinity, resulting in reduced transparency and a more opaque appearance. The choice between random and block copolymer polypropylene depends on the balance desired between aesthetic appeal and mechanical performance in applications requiring clear or visually appealing materials.

Processing and Molding: Ease of Use in Manufacturing

Random Copolymer polypropylene offers superior clarity and flexibility, making it easier to process using injection molding and blow molding techniques due to its lower melting point and uniform melting behavior. Block Copolymer polypropylene exhibits enhanced impact resistance and higher stiffness but requires more precise temperature control during extrusion and molding to avoid flow inconsistencies. Manufacturers often prefer Random Copolymer PP for applications needing smooth surface finishes and efficient cycle times, while Block Copolymer PP suits durable, impact-demanding products despite more complex processing conditions.

Typical Applications of Random Copolymer Polypropylene

Random copolymer polypropylene is commonly used in packaging films, automotive components, and household goods due to its enhanced clarity, flexibility, and impact resistance. Its molecular structure provides improved heat sealing properties and better low-temperature toughness compared to homopolymer polypropylene. These characteristics make random copolymer PP ideal for applications requiring transparency and durability, such as food packaging, medical devices, and consumer product containers.

Common Uses of Block Copolymer Polypropylene

Block copolymer polypropylene is widely used in automotive parts, housewares, and flexible packaging due to its enhanced impact resistance and clarity compared to random copolymer PP. Its superior toughness and stress crack resistance make it ideal for applications requiring durability under mechanical stress, such as in appliance components and industrial containers. The material's ability to maintain rigidity while offering flexibility also suits it for medical devices and consumer goods that demand reliable performance and long-lasting quality.

Cost Analysis: Random vs Block Copolymer PP

Random copolymer polypropylene generally incurs lower production costs due to simpler polymerization processes and lower catalyst consumption compared to block copolymer polypropylene. Block copolymer polypropylene, while more expensive, offers enhanced impact resistance and clarity, which justifies its higher cost in applications demanding superior mechanical properties. Manufacturers must balance these cost differences against performance requirements to optimize material selection for specific uses.

Environmental Considerations and Recyclability

Random copolymer polypropylene (PP) generally exhibits improved flexibility and clarity, but its heterogeneous polymer structure can complicate recycling processes due to varied melting points and additive distributions. Block copolymer PP, with its distinct blocks of homopolymer and copolymer segments, tends to offer better mechanical performance and more consistent thermal properties, facilitating more efficient sorting and recycling in industrial settings. Both materials contribute to environmental sustainability when recycled properly, yet block copolymer PP often enables higher-quality recycled outputs, reducing waste and resource consumption over multiple life cycles.

Random Copolymer PP vs Block Copolymer PP Infographic

materialdif.com

materialdif.com