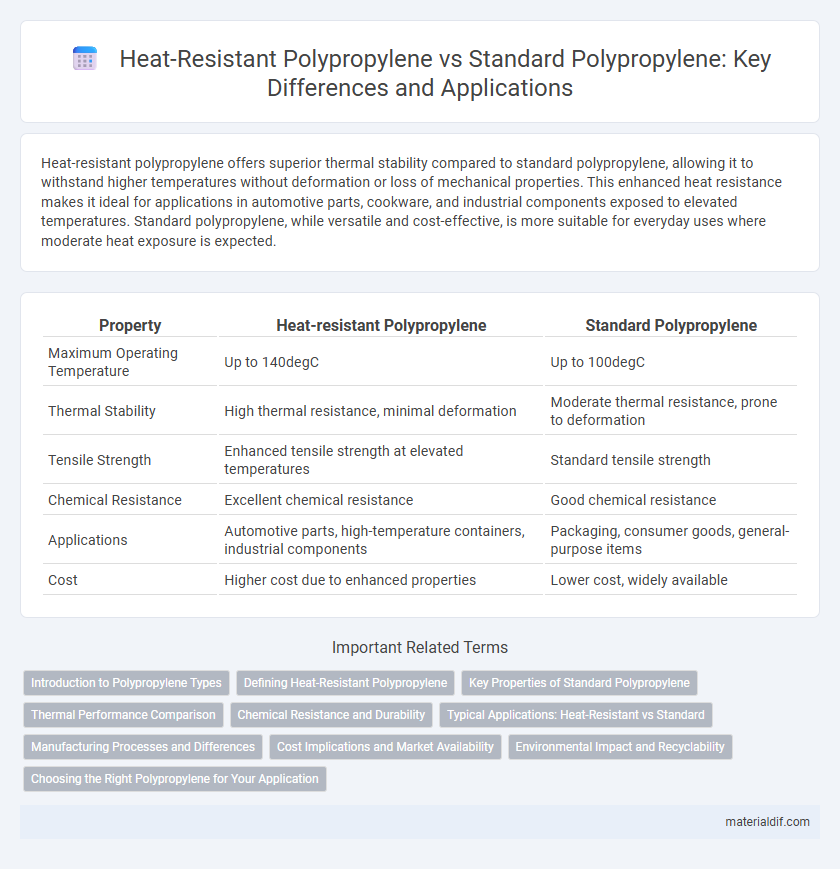

Heat-resistant polypropylene offers superior thermal stability compared to standard polypropylene, allowing it to withstand higher temperatures without deformation or loss of mechanical properties. This enhanced heat resistance makes it ideal for applications in automotive parts, cookware, and industrial components exposed to elevated temperatures. Standard polypropylene, while versatile and cost-effective, is more suitable for everyday uses where moderate heat exposure is expected.

Table of Comparison

| Property | Heat-resistant Polypropylene | Standard Polypropylene |

|---|---|---|

| Maximum Operating Temperature | Up to 140degC | Up to 100degC |

| Thermal Stability | High thermal resistance, minimal deformation | Moderate thermal resistance, prone to deformation |

| Tensile Strength | Enhanced tensile strength at elevated temperatures | Standard tensile strength |

| Chemical Resistance | Excellent chemical resistance | Good chemical resistance |

| Applications | Automotive parts, high-temperature containers, industrial components | Packaging, consumer goods, general-purpose items |

| Cost | Higher cost due to enhanced properties | Lower cost, widely available |

Introduction to Polypropylene Types

Heat-resistant polypropylene (HRPP) exhibits enhanced thermal stability with a melting point around 170degC, making it suitable for applications requiring prolonged exposure to high temperatures. Standard polypropylene typically melts at approximately 160degC and is widely used for everyday products like packaging and textiles due to its balance of strength and flexibility. The distinction between these polypropylene types lies in their molecular structure and additives, which directly influence their heat endurance and mechanical properties.

Defining Heat-Resistant Polypropylene

Heat-resistant polypropylene is a specially engineered variant of standard polypropylene designed to withstand higher temperatures without deforming or losing mechanical properties. This material typically incorporates additives or undergoes molecular modifications that enhance its thermal stability, allowing it to maintain performance in applications reaching temperatures above 100degC. Unlike standard polypropylene, which softens around 160degC, heat-resistant polypropylene retains strength and dimensional integrity in high-temperature environments such as automotive engine components and household appliances.

Key Properties of Standard Polypropylene

Standard polypropylene exhibits excellent chemical resistance, high tensile strength, and low density, making it lightweight and durable for various applications. Its melting point ranges around 160-170degC, providing moderate heat resistance suitable for everyday use but limiting performance in high-temperature environments. The material's impact resistance and flexibility contribute to its versatility in packaging, automotive parts, and household goods.

Thermal Performance Comparison

Heat-resistant polypropylene exhibits superior thermal stability with a melting point around 170degC compared to standard polypropylene's melting range of 130-160degC, enabling better performance in high-temperature applications. Its enhanced thermal resistance reduces deformation and mechanical property degradation under prolonged heat exposure, making it ideal for automotive and industrial components. Standard polypropylene, while cost-effective, tends to soften and lose strength quicker when subjected to elevated temperatures.

Chemical Resistance and Durability

Heat-resistant polypropylene exhibits superior chemical resistance compared to standard polypropylene, maintaining stability against acids, bases, and solvents at elevated temperatures. Its enhanced durability enables prolonged use in harsh environments without degradation or loss of mechanical properties. Standard polypropylene, while cost-effective and versatile, has limited heat tolerance and reduced resistance to aggressive chemicals under thermal stress.

Typical Applications: Heat-Resistant vs Standard

Heat-resistant polypropylene is commonly utilized in automotive parts, electrical components, and kitchenware where exposure to elevated temperatures is frequent, maintaining structural integrity up to 110degC. Standard polypropylene finds typical applications in packaging, disposable containers, and household items with lower thermal demands, performing effectively at temperatures up to 80degC. The enhanced thermal stability of heat-resistant polypropylene allows it to replace standard grades in demanding environments requiring longer service life and resistance to thermal deformation.

Manufacturing Processes and Differences

Heat-resistant polypropylene (HRPP) is engineered through specialized manufacturing processes such as metallocene catalysis and nucleating agents addition, enhancing its thermal stability beyond standard polypropylene. Standard polypropylene is produced using conventional Ziegler-Natta catalysts, resulting in lower heat deflection temperatures and reduced resistance to prolonged thermal exposure. HRPP's molecular structure modifications lead to improved crystallinity and melting point, making it suitable for applications requiring sustained high-temperature performance.

Cost Implications and Market Availability

Heat-resistant polypropylene typically incurs higher production costs due to specialized additives and modified polymer structures designed to withstand elevated temperatures, impacting overall pricing compared to standard polypropylene. Market availability of heat-resistant polypropylene is more limited, predominantly supplied by niche manufacturers catering to industrial sectors requiring enhanced thermal performance. Standard polypropylene remains widely accessible and more cost-effective, favored for general-purpose applications with moderate temperature demands.

Environmental Impact and Recyclability

Heat-resistant polypropylene exhibits enhanced thermal stability, enabling longer product lifespans and reduced material waste compared to standard polypropylene, which degrades faster under high temperatures. The improved durability of heat-resistant polypropylene lowers environmental impact by minimizing frequent replacements and decreasing landfill contributions. Both types maintain high recyclability rates, but heat-resistant variants often require specialized recycling processes to preserve their thermal properties, slightly complicating material recovery efforts.

Choosing the Right Polypropylene for Your Application

Heat-resistant polypropylene offers superior thermal stability with a melting point around 170degC, making it ideal for applications requiring sustained exposure to elevated temperatures. Standard polypropylene, with a lower melting point near 160degC, suits general-purpose uses where extreme heat resistance is not critical. Selecting the right polypropylene depends on factors like operating temperature, chemical exposure, and mechanical stress to ensure optimal performance and durability in your specific application.

Heat-resistant Polypropylene vs Standard Polypropylene Infographic

materialdif.com

materialdif.com