Polypropylene injection molding produces complex, high-precision parts by injecting molten polymer into detailed molds, ideal for creating intricate shapes with tight tolerances. Polypropylene extrusion, however, continuously shapes molten polymer into consistent profiles like sheets, pipes, or films, enabling efficient mass production with uniform thickness. Choosing between these processes depends on the required product geometry, volume, and application, with injection molding preferred for detailed components and extrusion suited for long, continuous shapes.

Table of Comparison

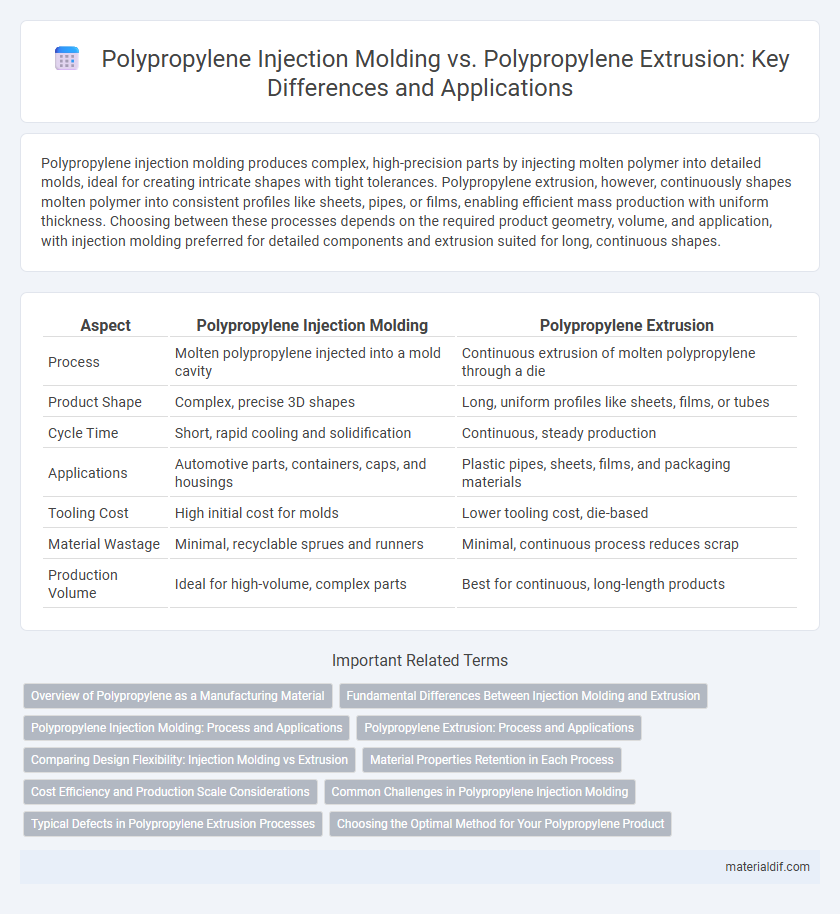

| Aspect | Polypropylene Injection Molding | Polypropylene Extrusion |

|---|---|---|

| Process | Molten polypropylene injected into a mold cavity | Continuous extrusion of molten polypropylene through a die |

| Product Shape | Complex, precise 3D shapes | Long, uniform profiles like sheets, films, or tubes |

| Cycle Time | Short, rapid cooling and solidification | Continuous, steady production |

| Applications | Automotive parts, containers, caps, and housings | Plastic pipes, sheets, films, and packaging materials |

| Tooling Cost | High initial cost for molds | Lower tooling cost, die-based |

| Material Wastage | Minimal, recyclable sprues and runners | Minimal, continuous process reduces scrap |

| Production Volume | Ideal for high-volume, complex parts | Best for continuous, long-length products |

Overview of Polypropylene as a Manufacturing Material

Polypropylene's versatility as a manufacturing material is highlighted in both injection molding and extrusion processes, each leveraging its chemical resistance, lightweight nature, and durability. Injection molding creates complex, high-precision components by melting and injecting polypropylene into molds, ideal for producing detailed parts with tight tolerances. Extrusion shapes continuous profiles such as pipes and sheets by forcing molten polypropylene through a die, optimizing efficiency for large-scale production of uniform cross-sectional items.

Fundamental Differences Between Injection Molding and Extrusion

Polypropylene injection molding involves injecting molten polymer into a mold cavity to create complex, detailed shapes with precise dimensions, whereas polypropylene extrusion pushes melted material through a die to produce continuous profiles like sheets or tubes. Injection molding offers high dimensional accuracy and is ideal for producing intricate parts in large volumes, while extrusion is suited for manufacturing consistent cross-sectional products efficiently. The fundamental difference lies in their process mechanics: injection molding is a discrete shaping method requiring molds, whereas extrusion is a continuous forming process driven by a die.

Polypropylene Injection Molding: Process and Applications

Polypropylene injection molding involves melting polypropylene pellets and injecting the molten polymer into a mold cavity under high pressure to form precise and complex shapes with excellent surface finish. This process is widely used in manufacturing automotive parts, medical devices, consumer goods, and packaging components due to its ability to produce high-strength, durable, and lightweight products. The rapid cooling in injection molding enables high production rates and consistency, making it ideal for mass production of intricate polypropylene components.

Polypropylene Extrusion: Process and Applications

Polypropylene extrusion involves melting polypropylene pellets and forcing the molten polymer through a shaped die to form continuous profiles such as pipes, sheets, and films. This process ensures uniform thickness and consistent quality, making it ideal for manufacturing packaging materials, automotive parts, and construction components. The versatility and efficiency of polypropylene extrusion enable high-volume production with excellent mechanical properties and chemical resistance.

Comparing Design Flexibility: Injection Molding vs Extrusion

Polypropylene injection molding offers superior design flexibility by enabling the creation of complex, intricate shapes with tight tolerances and detailed features, whereas extrusion primarily produces continuous profiles with uniform cross-sections. Injection molding supports multi-cavity molds and inserts, facilitating varied geometries within a single run, while extrusion is limited to simpler, linear designs. Consequently, products requiring elaborate contours or precise dimensions benefit more from injection molding than from extrusion processes.

Material Properties Retention in Each Process

Polypropylene injection molding offers superior control over complex geometries and maintains excellent dimensional stability, resulting in enhanced material properties retention such as impact resistance and tensile strength. In contrast, polypropylene extrusion delivers continuous shapes with consistent mechanical properties but may experience slight degradation in thermal stability due to prolonged heat exposure. Selecting the appropriate process depends on the desired balance between intricate design requirements and preserving the intrinsic properties of polypropylene for end-use applications.

Cost Efficiency and Production Scale Considerations

Polypropylene injection molding excels in producing complex, high-precision parts with lower labor costs per unit at large production volumes, making it cost-efficient for mass manufacturing. In contrast, polypropylene extrusion offers a continuous production process ideal for high-volume runs of uniform profiles, reducing material waste and energy consumption, thus optimizing cost efficiency for large-scale operations. Selecting between these methods depends on the desired product complexity and production scale, with injection molding suited for intricate shapes and extrusion preferred for simpler, continuous forms.

Common Challenges in Polypropylene Injection Molding

Polypropylene injection molding faces common challenges such as warping, sink marks, and inconsistent shrinkage due to uneven cooling rates and material flow. Unlike extrusion, where continuous profiles are formed, injection molding requires precise control of injection speed, mold temperature, and packing pressure to achieve optimal part quality. Managing polypropylene's high shrinkage rate and ensuring proper gate design are critical to minimizing defects and maintaining dimensional accuracy.

Typical Defects in Polypropylene Extrusion Processes

Typical defects in polypropylene extrusion processes include surface irregularities such as melt fracture, sharkskin, and die drool, which are caused by improper melt flow and temperature control. Dimensional inaccuracies and internal voids often arise from inconsistent cooling rates and inadequate pressure during extrusion. These defects reduce the structural integrity and appearance of polypropylene products compared to injection molding, where precision and surface finish are generally better controlled.

Choosing the Optimal Method for Your Polypropylene Product

Polypropylene injection molding offers precise, complex shapes and high production speed, ideal for manufacturing detailed components or high-volume runs. Polypropylene extrusion excels in creating continuous profiles like pipes and sheets with consistent cross-sections, making it optimal for applications requiring long lengths and uniformity. Selecting the optimal method depends on product design complexity, production volume, and dimensional requirements, ensuring cost-effectiveness and functionality.

Polypropylene Injection Molding vs Polypropylene Extrusion Infographic

materialdif.com

materialdif.com