Impact polypropylene exhibits enhanced toughness and resistance to sudden shocks compared to standard polypropylene, making it ideal for applications requiring greater durability. Its molecular structure is modified to improve impact strength without compromising the material's inherent lightweight and chemical resistance properties. This makes impact polypropylene a preferred choice in automotive parts, packaging, and consumer goods where improved performance under stress is critical.

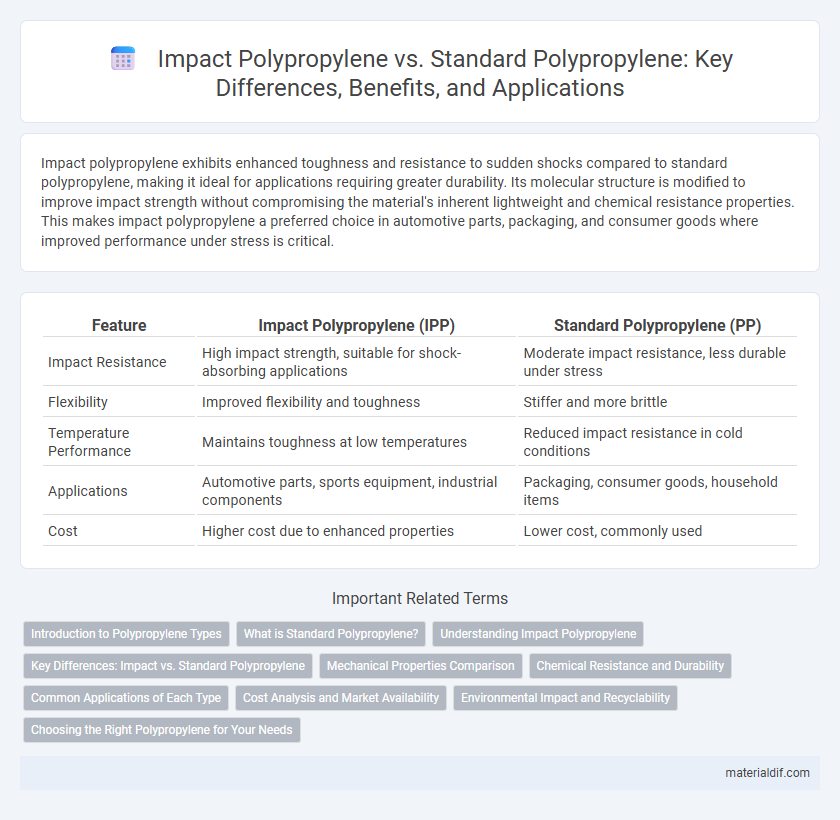

Table of Comparison

| Feature | Impact Polypropylene (IPP) | Standard Polypropylene (PP) |

|---|---|---|

| Impact Resistance | High impact strength, suitable for shock-absorbing applications | Moderate impact resistance, less durable under stress |

| Flexibility | Improved flexibility and toughness | Stiffer and more brittle |

| Temperature Performance | Maintains toughness at low temperatures | Reduced impact resistance in cold conditions |

| Applications | Automotive parts, sports equipment, industrial components | Packaging, consumer goods, household items |

| Cost | Higher cost due to enhanced properties | Lower cost, commonly used |

Introduction to Polypropylene Types

Impact polypropylene features enhanced impact resistance due to the incorporation of rubber modifiers, differentiating it from standard polypropylene which has higher stiffness but lower toughness. Standard polypropylene offers excellent chemical resistance and dimensional stability, making it ideal for rigid applications. The selection between impact and standard polypropylene depends on the required balance of strength, flexibility, and durability in end-use products.

What is Standard Polypropylene?

Standard polypropylene is a thermoplastic polymer widely used for its excellent chemical resistance, low cost, and good tensile strength in applications like packaging, textiles, and automotive components. It is known for its rigidity and relatively low impact resistance compared to its counterpart, impact polypropylene (IPP). Standard polypropylene's crystalline structure delivers robustness for structural parts but often requires modification when flexibility or shock absorption is needed.

Understanding Impact Polypropylene

Impact polypropylene (IPP) differs from standard polypropylene by incorporating elastomers to enhance its toughness and impact resistance, making it ideal for applications requiring durability under stress. By blending polypropylene with impact modifiers, IPP achieves improved flexibility and reduced brittleness at low temperatures without sacrificing chemical resistance or processability. This makes impact polypropylene widely used in automotive parts, packaging, and consumer goods where enhanced mechanical performance is crucial.

Key Differences: Impact vs. Standard Polypropylene

Impact polypropylene features enhanced toughness and increased resistance to impact and stress cracking compared to standard polypropylene, making it ideal for applications requiring higher durability. Standard polypropylene offers superior rigidity and chemical resistance but tends to be more brittle under high-stress conditions. The molecular structure of impact polypropylene includes rubber modifiers that improve flexibility and impact strength, whereas standard polypropylene lacks these modifiers, resulting in different mechanical properties.

Mechanical Properties Comparison

Impact polypropylene exhibits significantly enhanced impact resistance and toughness compared to standard polypropylene, making it ideal for applications requiring greater durability under stress. Mechanical properties such as tensile strength and elongation at break are improved due to the incorporation of rubber modifiers in impact polypropylene, which absorb and dissipate energy more effectively. Standard polypropylene typically offers higher stiffness but lower impact strength, limiting its use in environments with dynamic or impact loading conditions.

Chemical Resistance and Durability

Impact polypropylene exhibits enhanced durability due to its modified copolymer structure, providing superior resistance to cracking under stress compared to standard polypropylene. Chemical resistance in impact polypropylene remains robust, effectively withstanding exposure to acids, alkalis, and organic solvents, similar to standard grades. This combination of improved toughness and reliable chemical stability makes impact polypropylene ideal for applications demanding higher mechanical resilience without compromising chemical performance.

Common Applications of Each Type

Impact polypropylene is extensively used in automotive components and industrial applications due to its enhanced toughness and resistance to impact, making it suitable for bumpers, protective cases, and safety helmets. Standard polypropylene, characterized by its rigidity and chemical resistance, is commonly found in packaging materials, household goods, and medical devices where structural integrity and lightweight properties are essential. Both types serve distinct roles in manufacturing, driven by the specific mechanical and durability requirements of their applications.

Cost Analysis and Market Availability

Impact polypropylene offers enhanced toughness and durability compared to standard polypropylene, which often translates to a slightly higher cost due to additional processing and material modifications. Standard polypropylene remains more cost-effective and widely available in global markets, making it the preferred choice for applications with less demanding mechanical requirements. Market availability of impact polypropylene is increasing as demand grows in automotive and packaging industries, but it still lags behind the extensive supply network established for standard polypropylene.

Environmental Impact and Recyclability

Impact polypropylene features enhanced toughness and is often produced through the incorporation of elastomers, which can affect its recyclability compared to standard polypropylene. Both types are recyclable, but standard polypropylene typically offers more straightforward recycling due to its homogeneity and wider processing acceptance. Environmental impact assessments show that while impact polypropylene's production may involve additional energy consumption, both materials contribute similarly to reducing plastic waste when properly recycled.

Choosing the Right Polypropylene for Your Needs

Impact polypropylene offers enhanced impact resistance compared to standard polypropylene, making it ideal for applications requiring greater durability and toughness. Standard polypropylene provides excellent chemical resistance and rigidity, suitable for everyday products where flexibility is less critical. Selecting the right polypropylene depends on balancing mechanical strength needs with environmental exposure and cost considerations.

Impact Polypropylene vs Standard Polypropylene Infographic

materialdif.com

materialdif.com