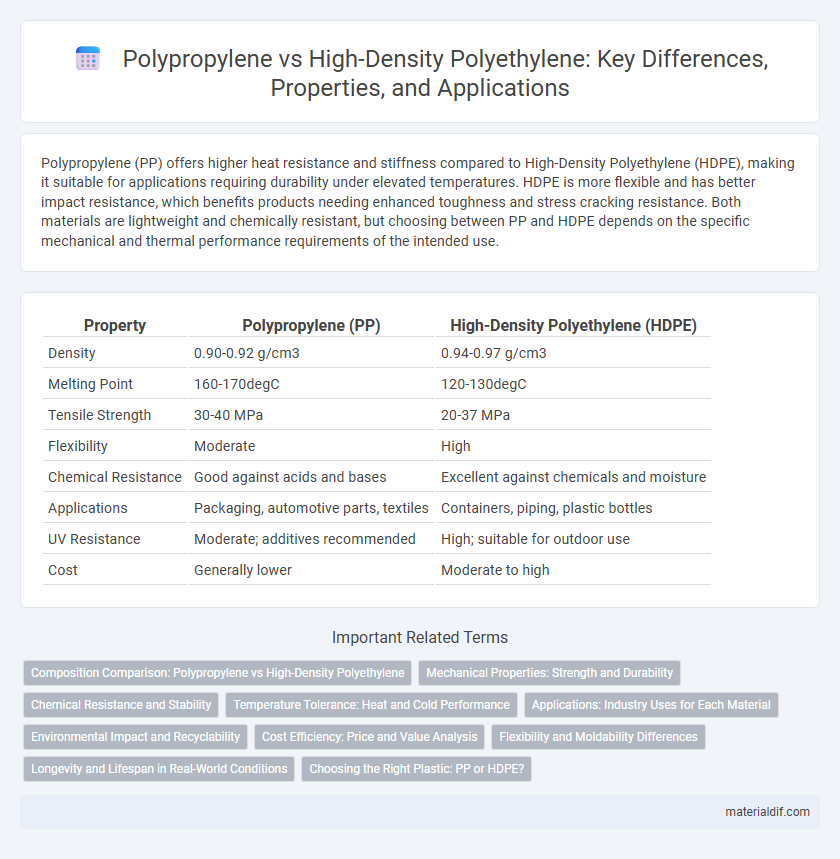

Polypropylene (PP) offers higher heat resistance and stiffness compared to High-Density Polyethylene (HDPE), making it suitable for applications requiring durability under elevated temperatures. HDPE is more flexible and has better impact resistance, which benefits products needing enhanced toughness and stress cracking resistance. Both materials are lightweight and chemically resistant, but choosing between PP and HDPE depends on the specific mechanical and thermal performance requirements of the intended use.

Table of Comparison

| Property | Polypropylene (PP) | High-Density Polyethylene (HDPE) |

|---|---|---|

| Density | 0.90-0.92 g/cm3 | 0.94-0.97 g/cm3 |

| Melting Point | 160-170degC | 120-130degC |

| Tensile Strength | 30-40 MPa | 20-37 MPa |

| Flexibility | Moderate | High |

| Chemical Resistance | Good against acids and bases | Excellent against chemicals and moisture |

| Applications | Packaging, automotive parts, textiles | Containers, piping, plastic bottles |

| UV Resistance | Moderate; additives recommended | High; suitable for outdoor use |

| Cost | Generally lower | Moderate to high |

Composition Comparison: Polypropylene vs High-Density Polyethylene

Polypropylene (PP) is a thermoplastic polymer composed of propylene monomers, characterized by a methyl group attached to every other carbon atom in its chain, providing increased rigidity and chemical resistance. High-Density Polyethylene (HDPE) consists of ethylene monomers with a linear carbon chain and minimal branching, resulting in higher density and tensile strength compared to low-density variants. The key compositional difference affects their physical properties, with PP exhibiting a higher melting point around 160degC and greater resistance to heat, while HDPE melts near 130degC and offers superior impact resistance and flexibility.

Mechanical Properties: Strength and Durability

Polypropylene (PP) exhibits higher tensile strength and stiffness compared to high-density polyethylene (HDPE), making it more suitable for applications requiring rigidity and impact resistance. HDPE demonstrates superior toughness and better resistance to environmental stress cracking, enhancing its durability in harsh conditions. Both polymers offer excellent chemical resistance, but polypropylene's higher melting point provides an advantage in high-temperature environments.

Chemical Resistance and Stability

Polypropylene exhibits superior chemical resistance to acids, bases, and organic solvents compared to High-Density Polyethylene, making it ideal for harsh chemical environments. Its higher melting point of approximately 160degC enhances thermal stability, enabling better performance in applications requiring heat resistance. HDPE, with a melting point around 130degC, offers good chemical resistance but is generally less stable under prolonged exposure to high temperatures and aggressive chemicals.

Temperature Tolerance: Heat and Cold Performance

Polypropylene exhibits superior heat resistance with a melting point around 160-170degC, making it ideal for high-temperature applications compared to High-Density Polyethylene's (HDPE) melting range of 120-130degC. Both materials perform well in cold environments, but HDPE tends to have better impact resistance at low temperatures due to its crystalline structure. Polypropylene's ability to maintain rigidity and chemical resistance at elevated temperatures distinguishes it in automotive and packaging industries requiring heat tolerance.

Applications: Industry Uses for Each Material

Polypropylene (PP) is widely used in automotive parts, medical devices, and packaging due to its excellent chemical resistance, flexibility, and fatigue resistance. High-Density Polyethylene (HDPE) finds extensive applications in piping systems, containers, and plastic bottles, benefiting from its high strength-to-density ratio and impact resistance. Both polymers are essential in manufacturing, with PP preferred for lightweight, flexible components and HDPE favored for durable, heavy-duty products.

Environmental Impact and Recyclability

Polypropylene (PP) and High-Density Polyethylene (HDPE) differ notably in environmental impact and recyclability, with HDPE typically achieving higher recycling rates due to its widespread acceptance in municipal recycling programs. PP's energy consumption during production is relatively lower, but it is less commonly recycled, leading to increased environmental persistence. Both materials contribute to plastic pollution, yet advancements in recycling technology and improved waste management strategies are essential to enhance their sustainability profiles.

Cost Efficiency: Price and Value Analysis

Polypropylene generally offers lower raw material costs compared to high-density polyethylene (HDPE), making it a more cost-effective option for applications requiring durability and chemical resistance. HDPE provides superior impact resistance and environmental stress cracking resistance, often justifying its higher price in long-term use cases. Evaluating price against performance, polypropylene delivers greater value in lightweight, low-cost packaging, while HDPE is preferred for heavy-duty containers and industrial applications due to enhanced strength and longevity.

Flexibility and Moldability Differences

Polypropylene exhibits greater flexibility compared to high-density polyethylene (HDPE), making it ideal for applications requiring repeated bending or impact resistance. Its superior moldability allows for complex shapes and precise detailing in injection molding, whereas HDPE tends to be more rigid and less capable of intricate designs. These differences influence material selection in industries such as automotive and packaging, where flexibility and detailed molding are critical.

Longevity and Lifespan in Real-World Conditions

Polypropylene offers a higher resistance to fatigue and chemical exposure compared to High-Density Polyethylene, contributing to a longer lifespan in demanding environments. In real-world conditions, polypropylene maintains structural integrity under repeated stress and elevated temperatures better than HDPE. This durability makes polypropylene ideal for applications requiring extended service life and consistent performance.

Choosing the Right Plastic: PP or HDPE?

Polypropylene (PP) offers higher melting points and better chemical resistance compared to High-Density Polyethylene (HDPE), making it ideal for applications requiring heat tolerance and stiffness. HDPE features superior impact resistance and moisture barrier properties, suited for containers and piping exposed to harsh environments. Selecting between PP and HDPE depends on specific factors like temperature requirements, flexibility, and exposure conditions to optimize performance and durability.

Polypropylene vs High-Density Polyethylene Infographic

materialdif.com

materialdif.com