Biaxially Oriented Polypropylene (BOPP) exhibits superior mechanical strength and dimensional stability due to its stretching in both machine and transverse directions, enhancing clarity and barrier properties compared to uniaxially oriented polypropylene. Uniaxially oriented polypropylene is stretched in only one direction, which provides better tensile strength in that axis but limits its overall flexibility and barrier efficiency. BOPP films are preferred in packaging applications requiring enhanced durability and moisture resistance, while uniaxially oriented polypropylene suits uses where directional strength is sufficient.

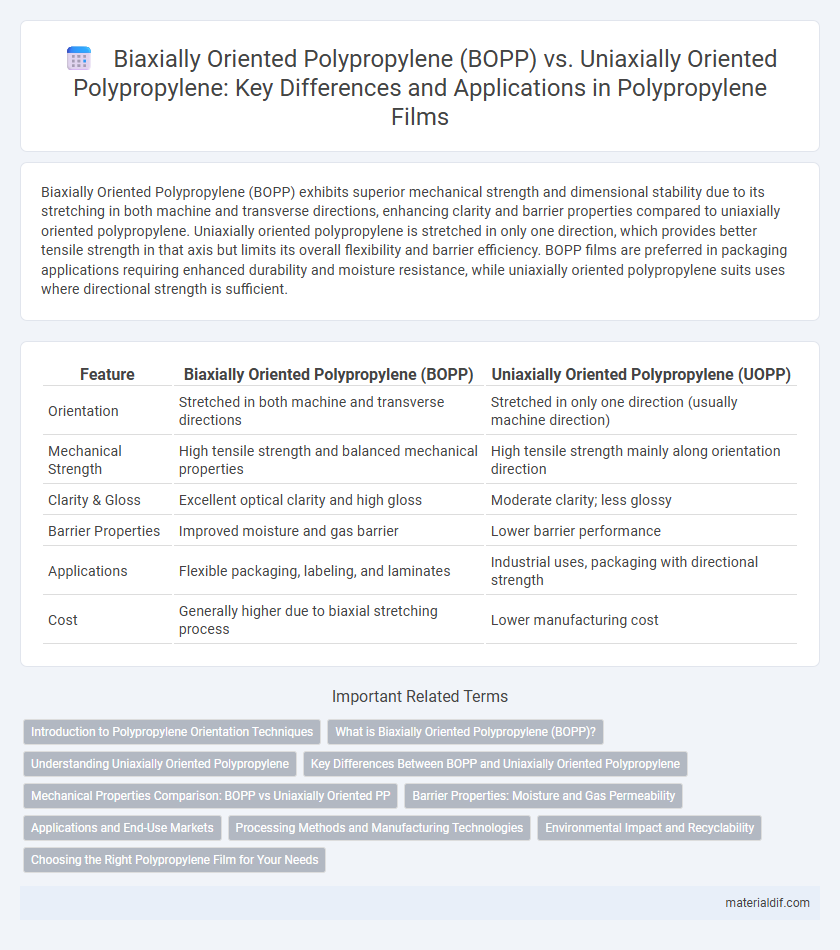

Table of Comparison

| Feature | Biaxially Oriented Polypropylene (BOPP) | Uniaxially Oriented Polypropylene (UOPP) |

|---|---|---|

| Orientation | Stretched in both machine and transverse directions | Stretched in only one direction (usually machine direction) |

| Mechanical Strength | High tensile strength and balanced mechanical properties | High tensile strength mainly along orientation direction |

| Clarity & Gloss | Excellent optical clarity and high gloss | Moderate clarity; less glossy |

| Barrier Properties | Improved moisture and gas barrier | Lower barrier performance |

| Applications | Flexible packaging, labeling, and laminates | Industrial uses, packaging with directional strength |

| Cost | Generally higher due to biaxial stretching process | Lower manufacturing cost |

Introduction to Polypropylene Orientation Techniques

Polypropylene orientation techniques enhance material properties by aligning polymer chains through stretching processes. Biaxially Oriented Polypropylene (BOPP) undergoes stretching in both machine and transverse directions, resulting in improved tensile strength, clarity, and barrier properties compared to Uniaxially Oriented Polypropylene (UOPP), which is stretched in only one direction. These orientation methods are essential for applications requiring specific mechanical and optical characteristics, such as flexible packaging and labeling.

What is Biaxially Oriented Polypropylene (BOPP)?

Biaxially Oriented Polypropylene (BOPP) is a polypropylene film stretched in two perpendicular directions, enhancing its strength, clarity, and barrier properties compared to Uniaxially Oriented Polypropylene, which is stretched in only one direction. This dual orientation improves tensile strength, dimensional stability, and resistance to moisture, making BOPP ideal for packaging, labeling, and lamination applications. BOPP's superior optical qualities and versatility in printing further distinguish it from uniaxially oriented variants.

Understanding Uniaxially Oriented Polypropylene

Uniaxially oriented polypropylene (UOPP) undergoes stretching in a single direction, resulting in enhanced tensile strength, stiffness, and improved barrier properties along the orientation axis. This orientation provides superior resistance to tear and impact forces in the stretched direction, making UOPP ideal for applications requiring directional strength. Compared to biaxially oriented polypropylene (BOPP), UOPP offers increased anisotropy, which benefits packaging films and tapes that prioritize strength in one direction.

Key Differences Between BOPP and Uniaxially Oriented Polypropylene

Biaxially Oriented Polypropylene (BOPP) is stretched both machine and transverse directions, enhancing tensile strength, clarity, and barrier properties, while Uniaxially Oriented Polypropylene (UOPP) is stretched in a single direction, typically improving strength and stiffness only along that axis. BOPP films exhibit superior dimensional stability and moisture resistance compared to UOPP, making them ideal for packaging applications demanding high clarity and durability. UOPP is generally more cost-effective but has limited mechanical properties and barrier performance relative to the multidirectional enhancements found in BOPP.

Mechanical Properties Comparison: BOPP vs Uniaxially Oriented PP

Biaxially Oriented Polypropylene (BOPP) exhibits superior mechanical properties compared to Uniaxially Oriented Polypropylene (UOPP), including enhanced tensile strength, improved dimensional stability, and greater impact resistance due to its orientation in both machine and transverse directions. UOPP offers higher stiffness and better tear resistance along the oriented axis but lacks the balanced strength and clarity of BOPP. These mechanical differences make BOPP ideal for packaging requiring uniform strength and clarity, while UOPP suits applications needing directional rigidity and toughness.

Barrier Properties: Moisture and Gas Permeability

Biaxially Oriented Polypropylene (BOPP) exhibits superior barrier properties compared to Uniaxially Oriented Polypropylene (UOPP), with significantly lower moisture vapor transmission rates due to its dual-axis stretching process that enhances film density and uniformity. BOPP films provide improved resistance against oxygen and other gases, reducing permeability and extending shelf life in packaging applications. In contrast, UOPP has higher gas permeability and moisture transmission, making it less effective for applications requiring rigorous barrier performance.

Applications and End-Use Markets

Biaxially Oriented Polypropylene (BOPP) films exhibit superior tensile strength, clarity, and barrier properties, making them ideal for packaging applications in food, pharmaceuticals, and consumer goods where visual appeal and product protection are critical. Uniaxially Oriented Polypropylene (UOPP) is primarily used in industrial applications such as lamination, labeling, and tape manufacturing, where mechanical strength is required predominantly in one direction. BOPP dominates flexible packaging and labeling markets, while UOPP finds niche end-use in specialty industrial films and technical components.

Processing Methods and Manufacturing Technologies

Biaxially Oriented Polypropylene (BOPP) is produced through simultaneous stretching in both the machine and transverse directions, typically using tenter frame or tubular film processes, enhancing its strength and clarity. Uniaxially Oriented Polypropylene (UOPP) undergoes stretching in only one direction, usually achieved by blow film extrusion or casting methods, resulting in films with improved tensile strength along the orientation axis but less isotropic properties. Advanced manufacturing technologies for BOPP emphasize precise temperature and tension control during orientation to achieve uniform thickness and superior barrier properties, while UOPP production focuses on optimizing single-direction molecular alignment for applications requiring directional strength.

Environmental Impact and Recyclability

Biaxially Oriented Polypropylene (BOPP) films offer enhanced mechanical properties and improved clarity compared to Uniaxially Oriented Polypropylene, but both types present challenges in recycling due to multilayer structures and additives that complicate material recovery. BOPP's widespread use in packaging leads to higher waste volumes, though advances in chemical recycling techniques show promise for better environmental management. Uniaxially Oriented Polypropylene, with simpler structure and lower density, tends to be easier to recycle but may sacrifice performance benefits seen in BOPP applications.

Choosing the Right Polypropylene Film for Your Needs

Biaxially Oriented Polypropylene (BOPP) offers enhanced strength, clarity, and barrier properties due to its stretched orientation in two directions, making it ideal for packaging requiring durability and visual appeal. Uniaxially Oriented Polypropylene (UOPP) provides flexibility and tensile strength in a single direction, suitable for applications needing controlled shrinkage or specific mechanical performance. Selecting between BOPP and UOPP depends on factors like required mechanical strength, transparency, and barrier properties to optimize film performance for packaging, labeling, or lamination uses.

Biaxially Oriented Polypropylene (BOPP) vs Uniaxially Oriented Polypropylene Infographic

materialdif.com

materialdif.com