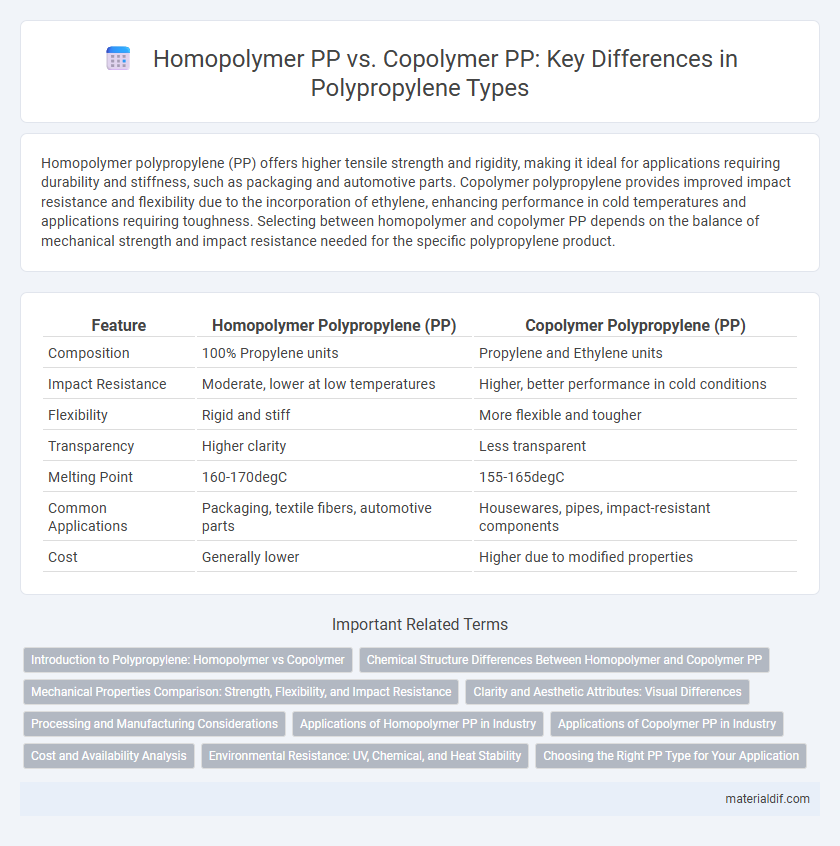

Homopolymer polypropylene (PP) offers higher tensile strength and rigidity, making it ideal for applications requiring durability and stiffness, such as packaging and automotive parts. Copolymer polypropylene provides improved impact resistance and flexibility due to the incorporation of ethylene, enhancing performance in cold temperatures and applications requiring toughness. Selecting between homopolymer and copolymer PP depends on the balance of mechanical strength and impact resistance needed for the specific polypropylene product.

Table of Comparison

| Feature | Homopolymer Polypropylene (PP) | Copolymer Polypropylene (PP) |

|---|---|---|

| Composition | 100% Propylene units | Propylene and Ethylene units |

| Impact Resistance | Moderate, lower at low temperatures | Higher, better performance in cold conditions |

| Flexibility | Rigid and stiff | More flexible and tougher |

| Transparency | Higher clarity | Less transparent |

| Melting Point | 160-170degC | 155-165degC |

| Common Applications | Packaging, textile fibers, automotive parts | Housewares, pipes, impact-resistant components |

| Cost | Generally lower | Higher due to modified properties |

Introduction to Polypropylene: Homopolymer vs Copolymer

Homopolymer polypropylene consists of a single type of propylene monomer, offering higher crystallinity, rigidity, and tensile strength, making it ideal for applications requiring firmness and clarity. Copolymer polypropylene incorporates ethylene monomers in addition to propylene, enhancing impact resistance and flexibility, which suits usage in products exposed to low temperatures or requiring greater toughness. Understanding these structural differences in homopolymer and copolymer PP is essential for selecting the appropriate grade based on mechanical properties and end-use performance.

Chemical Structure Differences Between Homopolymer and Copolymer PP

Homopolymer polypropylene consists of only propylene monomers linked in a regular, isotactic arrangement that provides high crystallinity and rigidity. In contrast, copolymer polypropylene incorporates ethylene monomers into the polymer chain, disrupting the regularity and reducing crystallinity, which enhances impact resistance and flexibility. The chemical structure difference influences thermal properties, mechanical strength, and processing behavior of homopolymer and copolymer polypropylene.

Mechanical Properties Comparison: Strength, Flexibility, and Impact Resistance

Homopolymer polypropylene (PP) offers higher tensile strength and stiffness, making it suitable for rigid applications, while copolymer polypropylene exhibits enhanced flexibility and improved impact resistance due to the incorporation of ethylene units. The mechanical properties of copolymer PP allow for better performance in low-temperature environments, reducing brittleness and increasing toughness compared to homopolymer PP. This balance of strength and flexibility makes copolymer PP ideal for applications requiring durability and resilience under mechanical stress.

Clarity and Aesthetic Attributes: Visual Differences

Homopolymer polypropylene (PP) exhibits higher clarity and a glossier, more transparent surface, making it ideal for applications where visual appearance is critical, such as packaging and consumer goods. In contrast, copolymer PP incorporates ethylene units that enhance impact resistance but reduce clarity, resulting in a more opaque and matte finish. The visual distinction between homopolymer and copolymer polypropylene significantly influences their selection based on aesthetic requirements and product design preferences.

Processing and Manufacturing Considerations

Homopolymer polypropylene (PP) offers higher crystallinity and stiffness, making it ideal for injection molding but requiring precise temperature control to avoid warping during processing. Copolymer PP, with its enhanced impact resistance from incorporated ethylene, provides greater flexibility in extrusion and thermoforming operations, allowing for easier processing at lower temperatures. Manufacturing considerations include selecting homopolymer PP for applications demanding rigidity and dimensional stability, while copolymer PP suits products needing improved toughness and reduced brittleness.

Applications of Homopolymer PP in Industry

Homopolymer polypropylene is widely used in the automotive industry for interior components, packaging films, and consumer goods due to its high tensile strength and rigidity. This type of polypropylene also finds applications in the production of household appliances, medical devices, and fibers where chemical resistance and durability are essential. Its superior fatigue resistance and dimensional stability make homopolymer PP ideal for manufacturing containers, pipes, and industrial parts that demand long-lasting performance.

Applications of Copolymer PP in Industry

Copolymer polypropylene (PP) finds extensive applications in the automotive industry for manufacturing durable interior components and under-the-hood parts due to its enhanced impact resistance and flexibility compared to homopolymer PP. In the packaging sector, copolymer PP is preferred for producing flexible films, containers, and lids that require higher clarity and toughness to protect contents. Medical devices and consumer goods also benefit from copolymer PP's improved thermal stability and chemical resistance, enabling the production of reliable, sterilizable products.

Cost and Availability Analysis

Homopolymer polypropylene (PP) generally offers lower costs due to simpler production processes and higher availability in global markets, making it a preferred choice for applications requiring rigidity and chemical resistance. Copolymer PP, which includes random and impact varieties, tends to be more expensive because of complex manufacturing and added material properties such as improved toughness and clarity, resulting in more limited availability. Price fluctuations for both types are influenced by raw material costs and regional demand, with homopolymers benefiting from more stable supply chains and broader industrial adoption.

Environmental Resistance: UV, Chemical, and Heat Stability

Homopolymer polypropylene exhibits superior chemical resistance and higher melting point, making it more stable under heat but less resistant to UV degradation compared to copolymer polypropylene. Copolymer polypropylene, with ethylene segments incorporated, offers enhanced flexibility and improved impact resistance at lower temperatures while demonstrating better UV stability and weathering performance. Both types resist most chemicals; however, homopolymer PP excels in applications requiring higher heat tolerance, whereas copolymer PP is preferable for environments with prolonged UV exposure.

Choosing the Right PP Type for Your Application

Homopolymer polypropylene offers higher tensile strength and rigidity, making it ideal for automotive parts and packaging requiring durability and resistance to stress. Copolymer polypropylene provides enhanced impact resistance and flexibility, suited for applications like medical devices and living hinges where toughness and elasticity are critical. Selecting between homopolymer and copolymer PP depends on balancing mechanical properties with specific end-use requirements such as temperature resistance, clarity, and impact performance.

Homopolymer PP vs Copolymer PP Infographic

materialdif.com

materialdif.com