Biaxially Oriented Polypropylene (BOPP) offers enhanced strength, clarity, and barrier properties compared to Cast Polypropylene, making it ideal for packaging applications requiring durability and transparency. BOPP is produced by stretching the film in both machine and transverse directions, resulting in improved stiffness and tensile strength. Cast Polypropylene, made by extruding the molten polymer onto a chill roll, provides excellent clarity and uniform thickness but generally lacks the mechanical strength and barrier performance of BOPP.

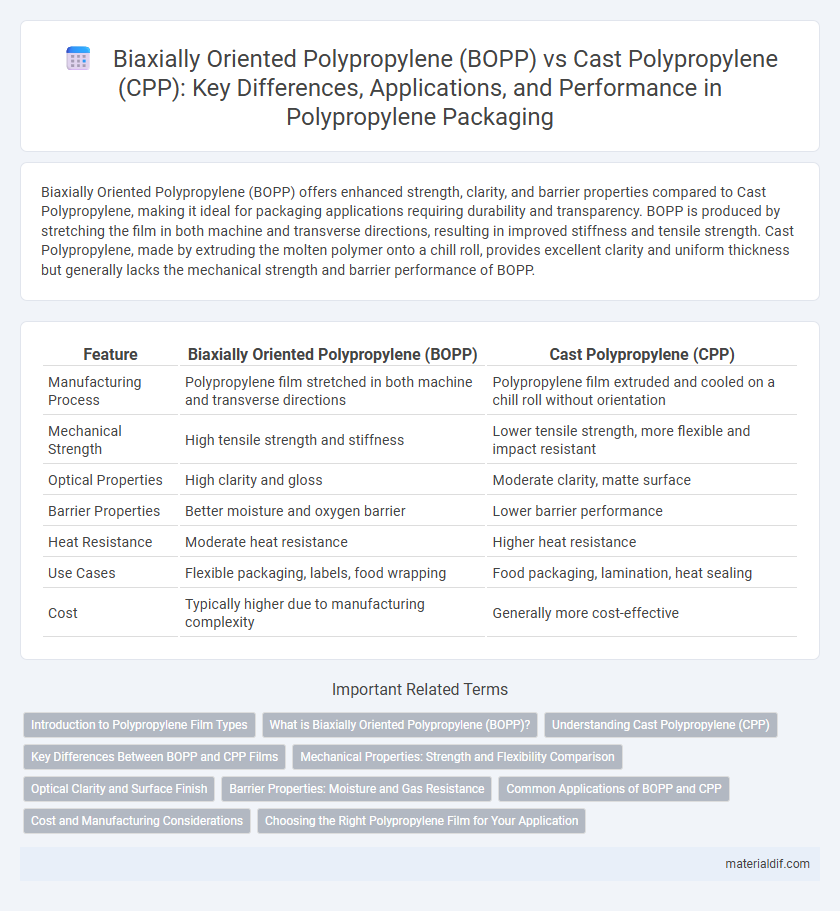

Table of Comparison

| Feature | Biaxially Oriented Polypropylene (BOPP) | Cast Polypropylene (CPP) |

|---|---|---|

| Manufacturing Process | Polypropylene film stretched in both machine and transverse directions | Polypropylene film extruded and cooled on a chill roll without orientation |

| Mechanical Strength | High tensile strength and stiffness | Lower tensile strength, more flexible and impact resistant |

| Optical Properties | High clarity and gloss | Moderate clarity, matte surface |

| Barrier Properties | Better moisture and oxygen barrier | Lower barrier performance |

| Heat Resistance | Moderate heat resistance | Higher heat resistance |

| Use Cases | Flexible packaging, labels, food wrapping | Food packaging, lamination, heat sealing |

| Cost | Typically higher due to manufacturing complexity | Generally more cost-effective |

Introduction to Polypropylene Film Types

Biaxially Oriented Polypropylene (BOPP) exhibits enhanced tensile strength, clarity, and barrier properties due to its biaxial stretching process, making it ideal for packaging applications requiring high durability and printability. Cast Polypropylene (CPP) film, produced through a casting method, offers superior heat sealability, flexibility, and softness, commonly used in food packaging and lamination. Both polypropylene film types serve distinct roles in industrial applications, optimizing performance based on mechanical and thermal property requirements.

What is Biaxially Oriented Polypropylene (BOPP)?

Biaxially Oriented Polypropylene (BOPP) is a polypropylene film stretched in both the machine and transverse directions, enhancing its tensile strength, clarity, and barrier properties compared to cast polypropylene. This orientation process improves stiffness, moisture resistance, and optical qualities, making BOPP ideal for packaging applications and labeling. In contrast, Cast Polypropylene is produced by extruding and cooling the polymer without stretching, resulting in a film with different mechanical and visual characteristics.

Understanding Cast Polypropylene (CPP)

Cast Polypropylene (CPP) is produced through a casting process that results in a film with excellent clarity, softness, and high tensile strength, making it ideal for flexible packaging applications. Unlike Biaxially Oriented Polypropylene (BOPP), CPP films exhibit better heat-sealability and higher moisture barrier properties, which enhance product protection and shelf life. The casting technique also allows CPP to maintain superior clarity and gloss while providing a softer hand feel compared to the stiffer structure of BOPP films.

Key Differences Between BOPP and CPP Films

Biaxially Oriented Polypropylene (BOPP) films are stretched in both machine and transverse directions, resulting in higher tensile strength, stiffness, and clarity compared to Cast Polypropylene (CPP) films, which are cooled and solidified from molten resin on a chill roll without orientation. BOPP films exhibit superior barrier properties against moisture and oxygen, making them ideal for food packaging, whereas CPP films offer enhanced heat sealability and flexibility suitable for lamination and pouch applications. The production processes differentiate their mechanical and optical characteristics, with BOPP providing better printability and CPP offering cost-effective, softer films.

Mechanical Properties: Strength and Flexibility Comparison

Biaxially Oriented Polypropylene (BOPP) exhibits superior tensile strength and stiffness due to its molecular orientation along two axes, enhancing durability and resistance to impact. In contrast, Cast Polypropylene (CPP) has greater flexibility and elongation at break, providing better tear resistance and adaptability in packaging applications. The mechanical properties of BOPP suit rigid and high-barrier requirements, while CPP is preferred for flexible, sealable films with excellent pliability.

Optical Clarity and Surface Finish

Biaxially Oriented Polypropylene (BOPP) exhibits superior optical clarity due to its biaxial stretching process, which enhances transparency and gloss. The surface finish of BOPP is smoother and more uniform compared to Cast Polypropylene (CPP), making it ideal for applications requiring high visual appeal. CPP, produced through a cast extrusion process, typically has lower clarity and a matte surface finish, suitable for packaging that prioritizes durability over aesthetics.

Barrier Properties: Moisture and Gas Resistance

Biaxially Oriented Polypropylene (BOPP) exhibits superior barrier properties against moisture and gases compared to Cast Polypropylene (CPP), owing to its stretched molecular structure that enhances film density and reduces permeability. BOPP films demonstrate significantly lower water vapor transmission rates (WVTR) and improved oxygen barrier performance, making them ideal for packaging sensitive food and pharmaceutical products. Conversely, CPP provides good moisture resistance but generally has higher gas permeability, limiting its use in applications where strong gas barrier properties are critical.

Common Applications of BOPP and CPP

Biaxially Oriented Polypropylene (BOPP) is widely used in food packaging, labels, and adhesive tapes due to its superior mechanical strength, clarity, and barrier properties. Cast Polypropylene (CPP) finds common applications in flexible packaging, lamination films, and medical packaging, benefiting from its excellent heat sealability and clarity. Both materials serve the packaging industry but cater to different functional requirements based on their distinct manufacturing processes.

Cost and Manufacturing Considerations

Biaxially Oriented Polypropylene (BOPP) involves a more complex manufacturing process with sequential stretching in both machine and transverse directions, leading to higher production costs compared to Cast Polypropylene (CPP), which is produced via a simpler extrusion process. BOPP films offer superior mechanical properties and clarity, justifying their increased expense in packaging and labeling applications, whereas CPP is favored for its cost-effectiveness and flexibility in applications requiring lower barrier properties. Cost efficiency and manufacturing speed make CPP suitable for high-volume, budget-sensitive products, while BOPP's enhanced durability supports premium packaging solutions.

Choosing the Right Polypropylene Film for Your Application

Biaxially Oriented Polypropylene (BOPP) offers superior tensile strength, clarity, and moisture barrier properties compared to Cast Polypropylene (CPP), making it ideal for packaging applications that require rigid and glossy films. Cast Polypropylene provides excellent heat sealability and flexibility, suited for applications needing softer films with high clarity and toughness. Selecting the right polypropylene film depends on balancing mechanical properties, optical clarity, shrink resistance, and sealing requirements specific to your product's packaging or industrial use.

Biaxially Oriented Polypropylene vs Cast Polypropylene Infographic

materialdif.com

materialdif.com