UV-stabilized polypropylene offers enhanced resistance to degradation caused by ultraviolet light, extending the material's durability and performance in outdoor applications compared to non-UV polypropylene. Non-UV polypropylene tends to become brittle and lose mechanical strength when exposed to prolonged sunlight, limiting its usefulness in environments with high UV exposure. Choosing UV-stabilized polypropylene ensures longer-lasting structural integrity and appearance for products exposed to natural light.

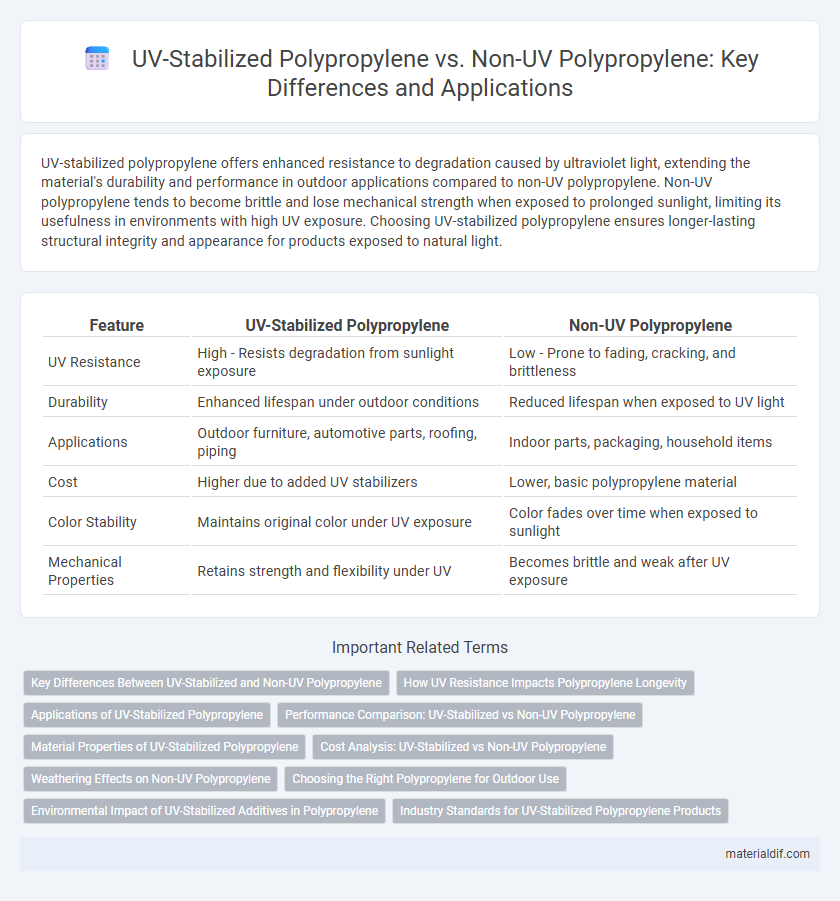

Table of Comparison

| Feature | UV-Stabilized Polypropylene | Non-UV Polypropylene |

|---|---|---|

| UV Resistance | High - Resists degradation from sunlight exposure | Low - Prone to fading, cracking, and brittleness |

| Durability | Enhanced lifespan under outdoor conditions | Reduced lifespan when exposed to UV light |

| Applications | Outdoor furniture, automotive parts, roofing, piping | Indoor parts, packaging, household items |

| Cost | Higher due to added UV stabilizers | Lower, basic polypropylene material |

| Color Stability | Maintains original color under UV exposure | Color fades over time when exposed to sunlight |

| Mechanical Properties | Retains strength and flexibility under UV | Becomes brittle and weak after UV exposure |

Key Differences Between UV-Stabilized and Non-UV Polypropylene

UV-stabilized polypropylene contains additives like UV absorbers or hindered amine light stabilizers (HALS) that protect the polymer from degradation caused by ultraviolet radiation, significantly enhancing its resistance to discoloration, brittleness, and loss of mechanical properties during prolonged outdoor exposure. Non-UV polypropylene lacks these protective additives, making it susceptible to rapid photodegradation, which results in surface cracking, fading, and reduced durability when exposed to sunlight. The key differences lie in the lifespan and performance of the materials in outdoor environments, where UV-stabilized polypropylene maintains structural integrity and appearance far longer than its non-UV counterpart.

How UV Resistance Impacts Polypropylene Longevity

UV-stabilized polypropylene contains additives that absorb ultraviolet radiation, significantly reducing polymer degradation caused by exposure to sunlight. This enhanced UV resistance prevents the breakdown of molecular chains, thereby extending the material's mechanical properties and overall lifespan compared to non-UV polypropylene. Consequently, UV-stabilized polypropylene is preferred for outdoor applications where prolonged durability and weather resistance are critical.

Applications of UV-Stabilized Polypropylene

UV-stabilized polypropylene is widely used in outdoor applications such as automotive parts, roofing membranes, and agricultural films where prolonged exposure to sunlight causes degradation in standard polypropylene. It offers enhanced resistance to UV radiation, preventing discoloration, loss of mechanical properties, and surface cracking, which ensures durability and longevity. These properties make UV-stabilized polypropylene ideal for products requiring long-term environmental exposure without compromising performance.

Performance Comparison: UV-Stabilized vs Non-UV Polypropylene

UV-stabilized polypropylene exhibits significantly enhanced resistance to photodegradation, maintaining mechanical strength, color, and flexibility after prolonged sun exposure compared to non-UV polypropylene, which rapidly deteriorates under ultraviolet radiation. The inclusion of UV stabilizers prevents polymer chain scission and surface cracking, extending the material's lifespan in outdoor applications. As a result, UV-stabilized polypropylene offers superior durability and reliability, reducing maintenance costs and ensuring consistent performance in environments with high UV exposure.

Material Properties of UV-Stabilized Polypropylene

UV-stabilized polypropylene contains additives such as UV absorbers and hindered amine light stabilizers (HALS) that protect the polymer chain from degradation caused by ultraviolet radiation. This enhanced material property improves durability, color retention, and mechanical strength when exposed to prolonged sunlight, making it ideal for outdoor applications. In contrast, non-UV polypropylene typically experiences surface cracking, discoloration, and reduced tensile properties under similar environmental conditions.

Cost Analysis: UV-Stabilized vs Non-UV Polypropylene

UV-stabilized polypropylene incurs higher initial costs due to the integration of UV inhibitors that enhance durability and extend product lifespan under sunlight exposure. Non-UV polypropylene, while cheaper upfront, may require more frequent replacements or maintenance when used outdoors, increasing long-term expenses. Evaluating total ownership cost reveals that UV-stabilized polypropylene often provides better value in applications exposed to UV radiation by minimizing degradation-related failures.

Weathering Effects on Non-UV Polypropylene

Non-UV stabilized polypropylene experiences significant degradation when exposed to prolonged UV radiation, leading to surface chalking, loss of mechanical strength, and color fading. The polymer chain undergoes photo-oxidative reactions, resulting in brittleness and micro-cracking that compromise material performance. Without UV stabilizers, weathering accelerates polymer embrittlement and reduces service life in outdoor applications.

Choosing the Right Polypropylene for Outdoor Use

UV-stabilized polypropylene contains additives that protect the polymer from degradation caused by ultraviolet radiation, making it ideal for outdoor applications exposed to sunlight. Non-UV polypropylene lacks these protective agents, resulting in brittleness, color fading, and reduced mechanical properties when used outdoors over time. Choosing UV-stabilized polypropylene ensures enhanced durability, longevity, and resistance to weathering in outdoor environments.

Environmental Impact of UV-Stabilized Additives in Polypropylene

UV-stabilized polypropylene incorporates additives that slow degradation caused by ultraviolet light, extending product lifespan and reducing plastic waste accumulation in the environment. However, these UV stabilizers can leach harmful chemicals during degradation, potentially contaminating soil and water ecosystems. Lifecycle assessments reveal that while UV stabilization improves durability, careful selection and formulation of additives are essential to minimize negative environmental impacts associated with their breakdown products.

Industry Standards for UV-Stabilized Polypropylene Products

UV-stabilized polypropylene meets stringent industry standards such as ASTM D4329 and ISO 4892, ensuring enhanced resistance to photodegradation and prolonged outdoor durability. These standards govern the testing of UV exposure, maintaining the material's mechanical integrity and colorfastness under prolonged sunlight. Non-UV polypropylene lacks these stabilizers and thus fails to comply with such standards, resulting in premature material failure and reduced lifespan in UV-exposed applications.

UV-Stabilized Polypropylene vs Non-UV Polypropylene Infographic

materialdif.com

materialdif.com