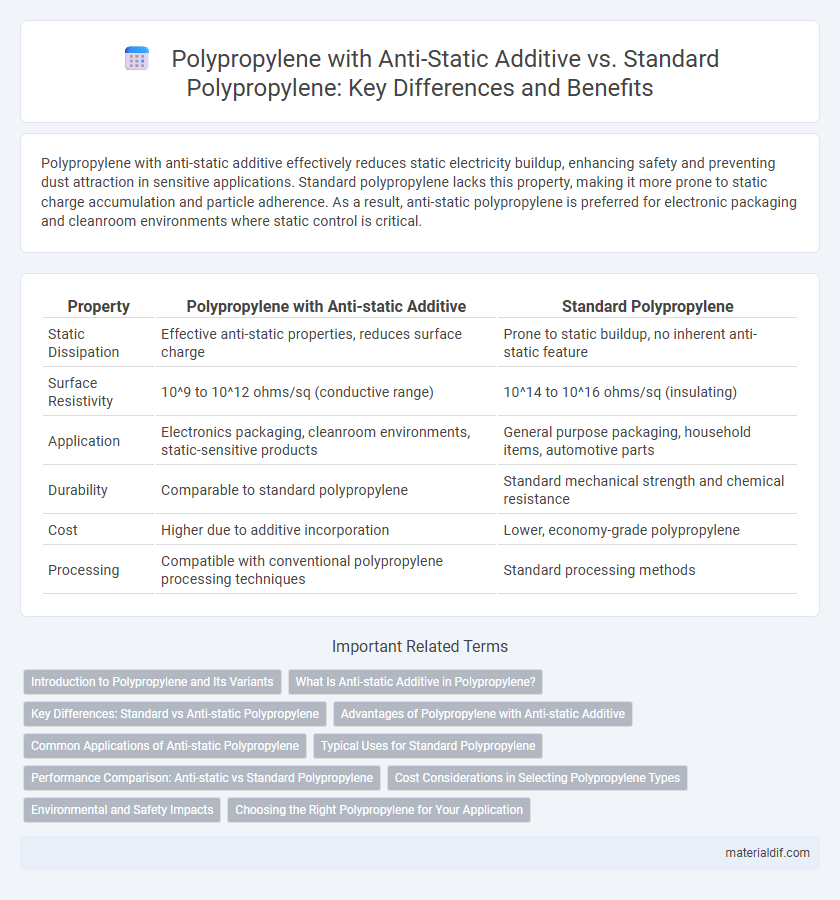

Polypropylene with anti-static additive effectively reduces static electricity buildup, enhancing safety and preventing dust attraction in sensitive applications. Standard polypropylene lacks this property, making it more prone to static charge accumulation and particle adherence. As a result, anti-static polypropylene is preferred for electronic packaging and cleanroom environments where static control is critical.

Table of Comparison

| Property | Polypropylene with Anti-static Additive | Standard Polypropylene |

|---|---|---|

| Static Dissipation | Effective anti-static properties, reduces surface charge | Prone to static buildup, no inherent anti-static feature |

| Surface Resistivity | 10^9 to 10^12 ohms/sq (conductive range) | 10^14 to 10^16 ohms/sq (insulating) |

| Application | Electronics packaging, cleanroom environments, static-sensitive products | General purpose packaging, household items, automotive parts |

| Durability | Comparable to standard polypropylene | Standard mechanical strength and chemical resistance |

| Cost | Higher due to additive incorporation | Lower, economy-grade polypropylene |

| Processing | Compatible with conventional polypropylene processing techniques | Standard processing methods |

Introduction to Polypropylene and Its Variants

Polypropylene with anti-static additive enhances the inherent properties of standard polypropylene by reducing static charge build-up, making it ideal for applications in electronics, packaging, and medical industries. Standard polypropylene offers excellent chemical resistance, tensile strength, and flexibility, commonly used in automotive parts, containers, and textiles. The anti-static variant improves safety and performance in environments sensitive to static electricity without compromising the durability and lightweight characteristics of standard polypropylene.

What Is Anti-static Additive in Polypropylene?

Anti-static additives in polypropylene reduce static electricity buildup by increasing the material's surface conductivity, preventing dust attraction and electrical discharge. These additives are typically surfactants or conductive polymers that migrate to the surface, enhancing the polymer's ability to dissipate static charge. Standard polypropylene lacks this feature, making it more prone to static-related issues in applications requiring static control.

Key Differences: Standard vs Anti-static Polypropylene

Polypropylene with anti-static additive contains specially engineered compounds that reduce surface electrical charge buildup, significantly enhancing static dissipation compared to standard polypropylene. This modification improves safety and product performance in environments sensitive to static electricity, such as electronic packaging and automotive components. Standard polypropylene lacks these additives, making it more prone to static accumulation, which can attract dust and increase the risk of sparks or interference.

Advantages of Polypropylene with Anti-static Additive

Polypropylene with anti-static additive offers enhanced surface conductivity, reducing static charge buildup that is common in standard polypropylene, thereby improving safety in environments prone to static discharge. This additive extends material performance by minimizing dust attraction and improving handling in manufacturing processes sensitive to static interference. Consequently, applications in electronics, packaging, and automotive industries benefit from increased reliability and reduced risk of damage caused by electrostatic discharge.

Common Applications of Anti-static Polypropylene

Polypropylene with anti-static additive is widely used in electronic packaging, cleanroom garments, and automotive components to prevent static electricity buildup that can damage sensitive electronic parts or attract dust and contaminants. Unlike standard polypropylene, which lacks this property, anti-static polypropylene enhances product safety and cleanliness in environments requiring static control. Its common applications include housing for electronic devices, lab equipment covers, and industrial floor mats where static discharge mitigation is crucial.

Typical Uses for Standard Polypropylene

Standard polypropylene is widely used in packaging, automotive parts, and household goods due to its excellent chemical resistance, durability, and low cost. It is ideal for applications where static discharge is not a critical concern, such as food containers, plastic furniture, and reusable storage bins. In contrast, polypropylene with anti-static additives is preferred in electronics and cleanroom environments to prevent static buildup and protect sensitive components.

Performance Comparison: Anti-static vs Standard Polypropylene

Polypropylene with anti-static additive exhibits significantly reduced surface resistivity, enhancing its ability to dissipate static charges compared to standard polypropylene, which tends to accumulate static electricity. This improved electrostatic discharge performance makes anti-static polypropylene ideal for electronic packaging and sensitive environments, where static build-up can cause damage. Standard polypropylene, while maintaining excellent mechanical properties and chemical resistance, lacks the conductive properties necessary to prevent static electricity effectively.

Cost Considerations in Selecting Polypropylene Types

Polypropylene with anti-static additive typically incurs higher raw material and processing costs compared to standard polypropylene due to the specialized compounds required for static dissipation. Standard polypropylene remains more cost-effective for applications where static control is non-essential, offering lower manufacturing expenses and broader availability. Evaluating total cost of ownership should include potential savings from reduced product damage and improved safety when selecting anti-static polypropylene over the standard variant.

Environmental and Safety Impacts

Polypropylene with anti-static additives reduces static electricity buildup, enhancing safety by minimizing fire hazards and electrostatic discharge risks in sensitive environments. Compared to standard polypropylene, these additives may introduce concerns regarding biodegradability and potential chemical leaching, impacting environmental sustainability. Selecting anti-static polypropylene requires balancing improved operational safety with careful evaluation of additive toxicity and end-of-life disposal effects.

Choosing the Right Polypropylene for Your Application

Polypropylene with anti-static additive significantly reduces static electricity buildup, making it ideal for electronic packaging, medical applications, and environments sensitive to dust attraction. Standard polypropylene offers excellent chemical resistance and durability but lacks inherent static dissipation, which can lead to clinging or dust accumulation in critical uses. Selecting polypropylene depends on application-specific needs for static control, ensuring product safety and performance in sensitive or high-precision environments.

Polypropylene with Anti-static Additive vs Standard Polypropylene Infographic

materialdif.com

materialdif.com