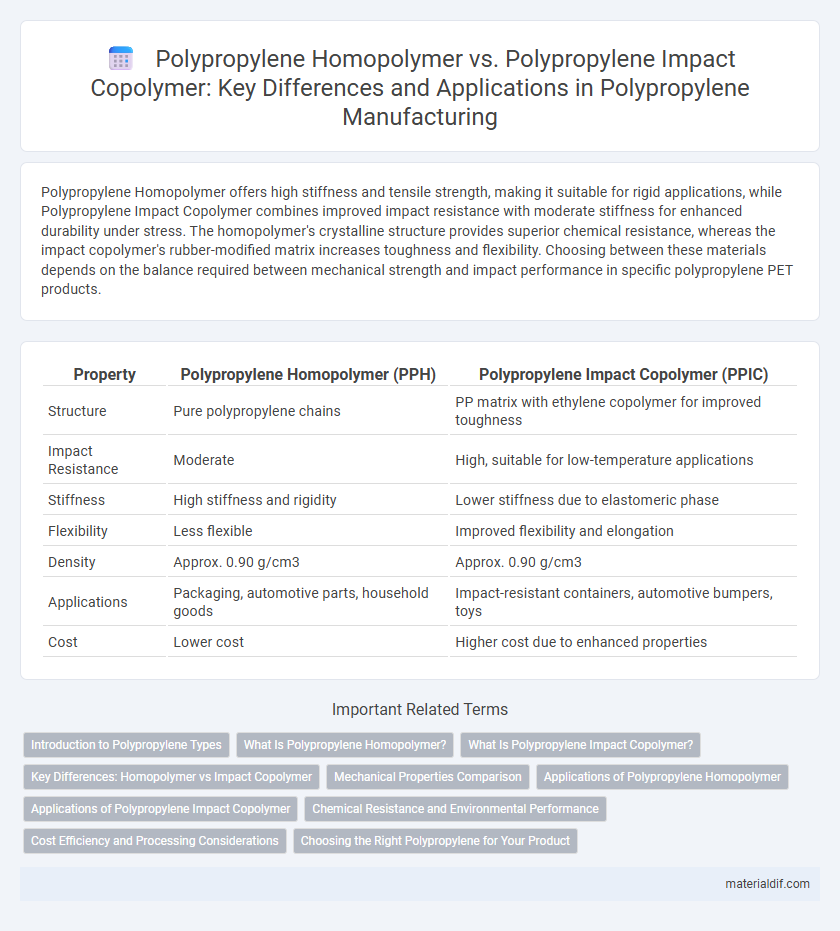

Polypropylene Homopolymer offers high stiffness and tensile strength, making it suitable for rigid applications, while Polypropylene Impact Copolymer combines improved impact resistance with moderate stiffness for enhanced durability under stress. The homopolymer's crystalline structure provides superior chemical resistance, whereas the impact copolymer's rubber-modified matrix increases toughness and flexibility. Choosing between these materials depends on the balance required between mechanical strength and impact performance in specific polypropylene PET products.

Table of Comparison

| Property | Polypropylene Homopolymer (PPH) | Polypropylene Impact Copolymer (PPIC) |

|---|---|---|

| Structure | Pure polypropylene chains | PP matrix with ethylene copolymer for improved toughness |

| Impact Resistance | Moderate | High, suitable for low-temperature applications |

| Stiffness | High stiffness and rigidity | Lower stiffness due to elastomeric phase |

| Flexibility | Less flexible | Improved flexibility and elongation |

| Density | Approx. 0.90 g/cm3 | Approx. 0.90 g/cm3 |

| Applications | Packaging, automotive parts, household goods | Impact-resistant containers, automotive bumpers, toys |

| Cost | Lower cost | Higher cost due to enhanced properties |

Introduction to Polypropylene Types

Polypropylene homopolymer features a high tensile strength and rigidity, making it suitable for applications requiring stiffness and clarity. In contrast, polypropylene impact copolymer incorporates ethylene, enhancing impact resistance and flexibility, ideal for automotive parts and packaging that demand durability. These distinctions influence the selection of polypropylene based on performance needs in diverse industrial applications.

What Is Polypropylene Homopolymer?

Polypropylene homopolymer is a type of polypropylene composed entirely of propylene monomers, known for its high tensile strength, stiffness, and chemical resistance, making it ideal for rigid packaging, automotive parts, and consumer goods. It exhibits a higher melting point and greater crystallinity compared to impact copolymer variants, which results in better mechanical properties but lower impact resistance. The material's uniform polymer structure allows for excellent dimensional stability and resistance to heat deformation in various industrial applications.

What Is Polypropylene Impact Copolymer?

Polypropylene Impact Copolymer is a type of polypropylene modified by incorporating ethylene segments to enhance its impact resistance and toughness compared to polypropylene homopolymer. This copolymer structure improves performance in low-temperature environments and applications requiring higher durability, such as automotive parts and packaging. Its balanced combination of stiffness and impact strength makes it suitable for products needing improved mechanical properties without sacrificing processability.

Key Differences: Homopolymer vs Impact Copolymer

Polypropylene homopolymer consists of a single type of polypropylene molecule, offering higher rigidity, tensile strength, and a higher melting point compared to impact copolymer. Impact copolymer incorporates ethylene segments, enhancing its impact resistance and flexibility, making it suitable for applications requiring durability under stress or low temperatures. The homopolymer suits products needing stiffness and resistance to wear, while impact copolymer is preferred for items exposed to impact and mechanical shocks.

Mechanical Properties Comparison

Polypropylene Homopolymer exhibits higher tensile strength and stiffness, making it suitable for applications requiring rigidity and structural integrity. Polypropylene Impact Copolymer offers enhanced impact resistance and toughness due to the incorporation of rubber particles, which improves performance under dynamic or low-temperature conditions. The mechanical property trade-off between these two types favors homopolymers for load-bearing uses and impact copolymers for durability in demanding environments.

Applications of Polypropylene Homopolymer

Polypropylene homopolymer is widely used in applications requiring high stiffness and excellent chemical resistance, such as automotive parts, packaging films, and consumer goods. Its superior tensile strength and clarity make it ideal for medical devices and household containers. The material's robust heat resistance and low moisture absorption further enable its use in industrial components and electrical appliances.

Applications of Polypropylene Impact Copolymer

Polypropylene Impact Copolymer offers enhanced toughness and impact resistance compared to Polypropylene Homopolymer, making it ideal for automotive parts, packaging films, and consumer goods that require durability under stress. Its improved flexibility and resistance to cracking enable applications in housewares, toys, and industrial containers where enhanced performance is critical. This copolymer's balanced mechanical properties extend its use to medical devices and electrical appliances demanding high impact strength and longevity.

Chemical Resistance and Environmental Performance

Polypropylene Homopolymer exhibits superior chemical resistance against acids, bases, and organic solvents due to its highly crystalline structure, making it ideal for use in harsh chemical environments. Polypropylene Impact Copolymer contains ethylene copolymers that enhance impact strength but slightly reduce chemical resistance, which can affect its durability when exposed to aggressive chemicals. Environmentally, both variants are recyclable thermoplastics, but Homopolymer's higher crystallinity contributes to better thermal stability and longer lifecycle in chemical applications.

Cost Efficiency and Processing Considerations

Polypropylene Homopolymer offers higher stiffness and tensile strength at a lower cost, making it an economical choice for applications requiring rigidity. Polypropylene Impact Copolymer provides superior impact resistance and flexibility, which increases processing complexity and material cost but enhances durability for dynamic environments. Processing considerations include Homopolymer's easier mold flow and faster cycle times, whereas Impact Copolymer demands controlled cooling and slower rates to optimize impact properties.

Choosing the Right Polypropylene for Your Product

Polypropylene homopolymer offers high stiffness, excellent chemical resistance, and superior tensile strength, making it ideal for applications requiring rigidity and durability. Polypropylene impact copolymer incorporates an elastomeric phase, enhancing impact resistance and toughness, which is crucial for products subjected to mechanical stress or low temperatures. Selecting the right polypropylene depends on the balance between mechanical properties and environmental conditions of the final product, ensuring optimal performance and longevity.

Polypropylene Homopolymer vs Polypropylene Impact Copolymer Infographic

materialdif.com

materialdif.com