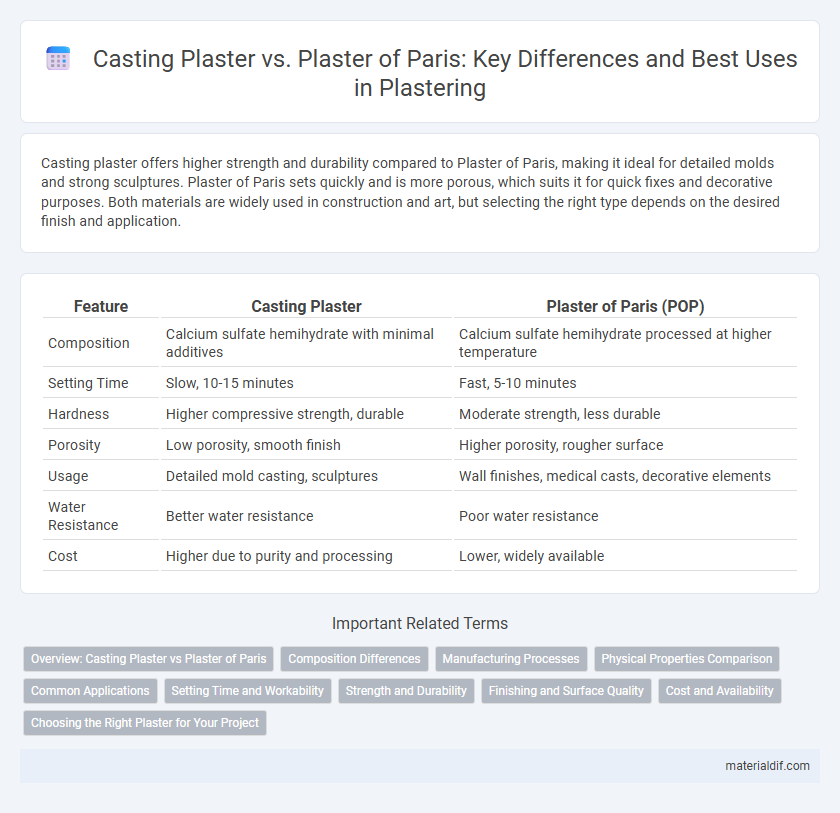

Casting plaster offers higher strength and durability compared to Plaster of Paris, making it ideal for detailed molds and strong sculptures. Plaster of Paris sets quickly and is more porous, which suits it for quick fixes and decorative purposes. Both materials are widely used in construction and art, but selecting the right type depends on the desired finish and application.

Table of Comparison

| Feature | Casting Plaster | Plaster of Paris (POP) |

|---|---|---|

| Composition | Calcium sulfate hemihydrate with minimal additives | Calcium sulfate hemihydrate processed at higher temperature |

| Setting Time | Slow, 10-15 minutes | Fast, 5-10 minutes |

| Hardness | Higher compressive strength, durable | Moderate strength, less durable |

| Porosity | Low porosity, smooth finish | Higher porosity, rougher surface |

| Usage | Detailed mold casting, sculptures | Wall finishes, medical casts, decorative elements |

| Water Resistance | Better water resistance | Poor water resistance |

| Cost | Higher due to purity and processing | Lower, widely available |

Overview: Casting Plaster vs Plaster of Paris

Casting plaster and Plaster of Paris are both widely used for molding and sculpting, but they differ in composition and setting properties. Casting plaster typically contains additives that improve strength and reduce brittleness, making it ideal for detailed molds and durable casts. Plaster of Paris sets quickly and is valued for its smooth finish and ease of use in decorative or medical applications.

Composition Differences

Casting plaster is primarily composed of calcium sulfate hemihydrate derived from natural gypsum, featuring a fine texture suitable for detailed molds and sculptures. Plaster of Paris also contains calcium sulfate hemihydrate but is more refined and processed to provide quick setting times and smoother finishes ideal for medical and artistic applications. The variations in particle size and purity between casting plaster and Plaster of Paris directly impact their workability, drying time, and surface hardness.

Manufacturing Processes

Casting plaster is produced by heating raw gypsum to a temperature of approximately 120degC to remove water content, resulting in a fine powder that sets slowly and provides a harder, more durable finish. Plaster of Paris, manufactured by heating gypsum to around 150degC to drive off chemically combined water, forms a finer powder that sets rapidly when mixed with water, making it ideal for quick molds and detailed casts. The difference in calcination temperatures and particle fineness during manufacturing influences their setting times, strength, and suitability for various applications.

Physical Properties Comparison

Casting plaster exhibits a lower setting temperature and finer particle size compared to Plaster of Paris, resulting in smoother surface finishes and reduced shrinkage during drying. Plaster of Paris typically has faster setting time but generates higher heat, which can affect delicate molds. The density of casting plaster is usually higher, providing enhanced strength and durability for detailed casts in sculpting and industrial applications.

Common Applications

Casting Plaster is widely used in mold making, sculpting, and architectural detailing due to its fine texture and smooth finish. Plaster of Paris is commonly utilized for medical casts, decorative elements, and quick-setting repairs because of its rapid hardening properties. Both materials serve distinct purposes in arts, construction, and healthcare based on their setting times and strength characteristics.

Setting Time and Workability

Casting plaster typically sets within 10 to 15 minutes, providing a longer workability window ideal for detailed molds and intricate designs. Plaster of Paris hardens faster, usually within 5 to 10 minutes, making it suitable for quick repairs but limiting the time available for manipulation. The slower setting time of casting plaster enhances smooth application and reduces the risk of cracks during drying.

Strength and Durability

Casting plaster exhibits higher compressive strength and enhanced durability compared to Plaster of Paris, making it ideal for mold making and structural applications. Plaster of Paris, while quick-setting and versatile, is more prone to chipping and lower long-term stability under stress. The denser molecular structure of casting plaster contributes significantly to its superior mechanical properties and resistance to wear.

Finishing and Surface Quality

Casting plaster offers a finer, smoother surface finish ideal for detailed molds and sculptural work, while Plaster of Paris tends to be more porous and less smooth, requiring additional sanding or sealing for a polished appearance. The higher purity and finer particle size of casting plaster contribute to its superior surface quality and reduced likelihood of air bubbles during setting. For projects demanding crisp edges and minimal post-processing, casting plaster is the preferred choice over Plaster of Paris.

Cost and Availability

Casting plaster generally costs more due to its higher purity and finer grain, making it ideal for detailed molds and sculptures. Plaster of Paris is widely available and more affordable, commonly used for quick repairs and basic molds. Both materials are easy to source, but Plaster of Paris offers better accessibility for everyday projects.

Choosing the Right Plaster for Your Project

Casting plaster offers a finer texture and slower setting time, making it ideal for detailed molds and sculptures, while plaster of Paris sets quickly and is preferred for fast repairs and casts. Choosing the right plaster depends on the project's complexity, drying time requirements, and final finish needed. For intricate art pieces, casting plaster ensures precision, whereas plaster of Paris suits architectural patching and lightweight applications.

Casting Plaster vs Plaster of Paris Infographic

materialdif.com

materialdif.com