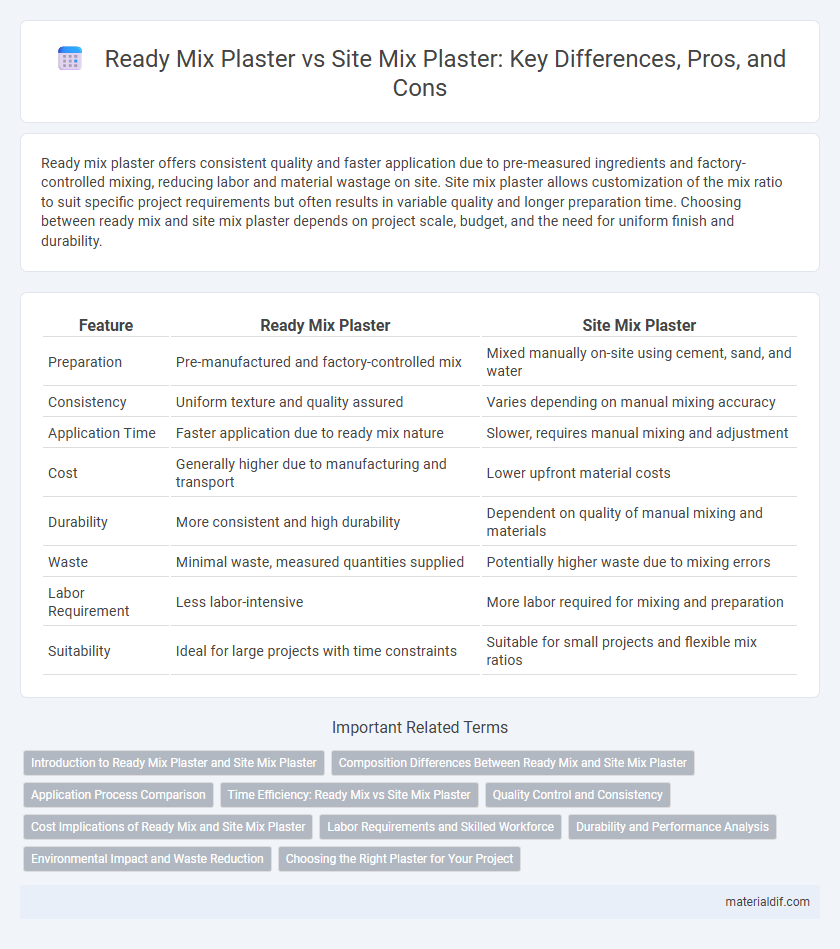

Ready mix plaster offers consistent quality and faster application due to pre-measured ingredients and factory-controlled mixing, reducing labor and material wastage on site. Site mix plaster allows customization of the mix ratio to suit specific project requirements but often results in variable quality and longer preparation time. Choosing between ready mix and site mix plaster depends on project scale, budget, and the need for uniform finish and durability.

Table of Comparison

| Feature | Ready Mix Plaster | Site Mix Plaster |

|---|---|---|

| Preparation | Pre-manufactured and factory-controlled mix | Mixed manually on-site using cement, sand, and water |

| Consistency | Uniform texture and quality assured | Varies depending on manual mixing accuracy |

| Application Time | Faster application due to ready mix nature | Slower, requires manual mixing and adjustment |

| Cost | Generally higher due to manufacturing and transport | Lower upfront material costs |

| Durability | More consistent and high durability | Dependent on quality of manual mixing and materials |

| Waste | Minimal waste, measured quantities supplied | Potentially higher waste due to mixing errors |

| Labor Requirement | Less labor-intensive | More labor required for mixing and preparation |

| Suitability | Ideal for large projects with time constraints | Suitable for small projects and flexible mix ratios |

Introduction to Ready Mix Plaster and Site Mix Plaster

Ready Mix Plaster is a pre-blended, factory-produced mixture that ensures consistent quality, faster application, and minimal wastage compared to traditional methods. Site Mix Plaster involves mixing raw materials like sand, cement, and lime manually on-site, offering flexibility but often varying in consistency and strength. Understanding the differences between these two types helps in selecting the appropriate plastering technique based on project requirements, labor skills, and environmental conditions.

Composition Differences Between Ready Mix and Site Mix Plaster

Ready mix plaster consists of a precise blend of hydrated lime, fine sand, and cement combined with additives for enhanced workability and durability, manufactured under controlled conditions. Site mix plaster involves manually mixing cement, sand, and water at the construction site, often resulting in variable consistency and strength due to less controlled proportions. The ready mix formula ensures uniform particle size and optimized chemical composition, leading to better bonding and reduced cracking compared to the traditional site mix plaster.

Application Process Comparison

Ready mix plaster offers a consistent blend of pre-mixed materials that simplifies the application process, reducing labor time and minimizing errors on-site. Site mix plaster requires manual mixing of cement, lime, and sand, demanding skilled labor to achieve uniform consistency and increasing the risk of material wastage. The controlled quality of ready mix plaster enhances efficiency, whereas site mix plaster allows for on-demand adjustments but with variable application quality.

Time Efficiency: Ready Mix vs Site Mix Plaster

Ready mix plaster significantly reduces application time due to its pre-mixed consistency, eliminating the need for on-site blending and minimizing preparation delays. Site mix plaster requires manual mixing, which can prolong project timelines and increase labor costs. Choosing ready mix plaster enhances overall time efficiency on construction projects, ensuring faster drywall finishing and quicker project turnover.

Quality Control and Consistency

Ready Mix Plaster offers superior quality control due to its factory production under standardized conditions, ensuring consistent mix proportions and uniformity in texture and strength. Site Mix Plaster often varies in quality because of on-site mixing inconsistencies, environmental factors, and manual measurement errors. The reliable consistency of Ready Mix Plaster reduces defects, improves finish durability, and minimizes material wastage compared to Site Mix Plaster.

Cost Implications of Ready Mix and Site Mix Plaster

Ready mix plaster typically incurs higher upfront costs due to factory production, packaging, and transportation expenses, but offers consistent quality and reduced labor time on site. Site mix plaster uses raw materials like cement, sand, and lime combined on location, resulting in lower material costs but potentially higher labor costs and variable quality depending on workmanship. Overall, ready mix plaster's controlled composition minimizes waste and rework expenses, while site mix plaster may require cost overruns linked to inconsistent mixing and longer application times.

Labor Requirements and Skilled Workforce

Ready Mix Plaster significantly reduces labor requirements due to its pre-blended composition, ensuring consistent quality and faster application compared to Site Mix Plaster, which demands more skilled labor for accurate proportioning and mixing on-site. Site Mix Plaster relies heavily on experienced workers to maintain the correct mix ratios and achieve uniform finishes, increasing the dependency on a skilled workforce. The efficiency of Ready Mix Plaster leads to lower labor costs and minimized human error, making it ideal for large-scale projects with tight deadlines.

Durability and Performance Analysis

Ready mix plaster demonstrates superior durability and consistent performance due to its precise factory-controlled formulation, ensuring uniform strength and resistance to cracking. Site mix plaster often varies in quality and durability because it relies on manual mixing and variable material ratios, which can lead to inconsistent bonding and surface finishing. Studies show ready mix plaster offers enhanced weather resistance and long-term structural integrity compared to site mix plaster in both interior and exterior applications.

Environmental Impact and Waste Reduction

Ready Mix Plaster offers a significant advantage in environmental impact by minimizing raw material wastage through precise factory-controlled batching, reducing excess plaster disposal typically seen in Site Mix Plaster. The controlled manufacturing process of Ready Mix Plaster ensures consistent quality and reduces the carbon footprint associated with on-site mixing equipment and transportation of multiple materials. Site Mix Plaster, often mixed on-site, tends to generate more waste and dust pollution, increasing environmental strain and inefficiencies in resource use.

Choosing the Right Plaster for Your Project

Ready mix plaster offers consistent quality and faster application, reducing labor costs and minimizing material wastage on site. Site mix plaster provides flexibility in mix ratios, allowing customization based on specific project requirements but often involves longer preparation time and potential inconsistencies. Selecting the right plaster depends on project scale, desired finish quality, budget constraints, and environmental conditions, ensuring optimal performance and durability.

Ready Mix Plaster vs Site Mix Plaster Infographic

materialdif.com

materialdif.com