Wet plastering involves applying a mixture of cement, sand, and water directly onto surfaces, resulting in a smooth, durable finish ideal for walls and ceilings. Dry plastering uses pre-made plasterboards fixed to the substrate, offering faster installation and reduced drying time. Wet plastering enhances surface strength and moisture resistance, while dry plastering provides flexibility and ease of repair in interior applications.

Table of Comparison

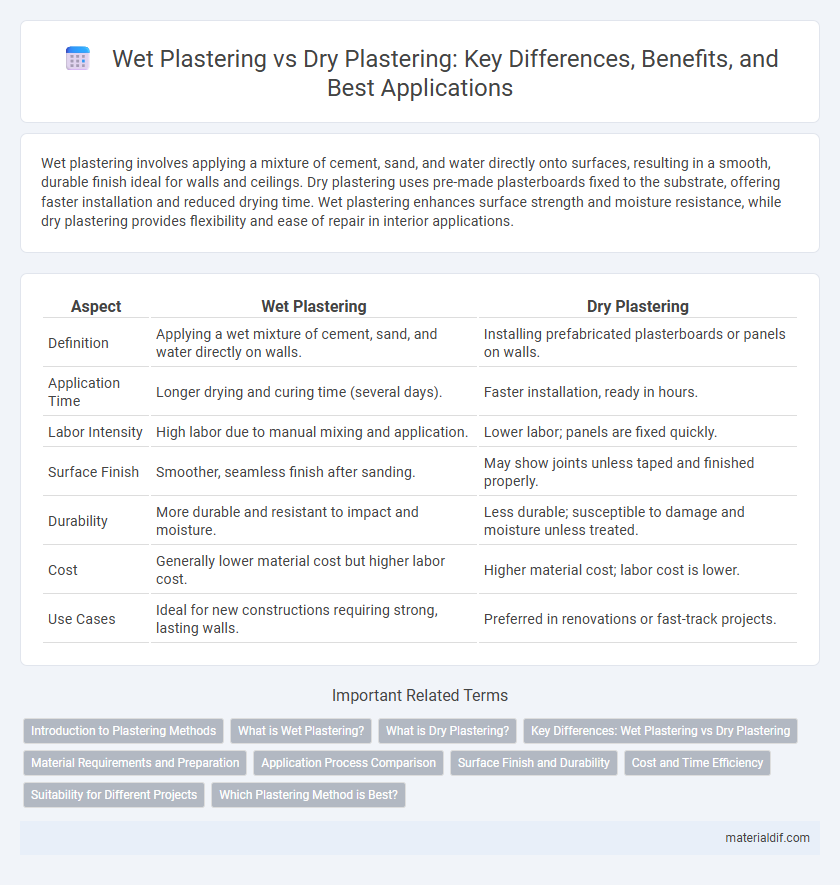

| Aspect | Wet Plastering | Dry Plastering |

|---|---|---|

| Definition | Applying a wet mixture of cement, sand, and water directly on walls. | Installing prefabricated plasterboards or panels on walls. |

| Application Time | Longer drying and curing time (several days). | Faster installation, ready in hours. |

| Labor Intensity | High labor due to manual mixing and application. | Lower labor; panels are fixed quickly. |

| Surface Finish | Smoother, seamless finish after sanding. | May show joints unless taped and finished properly. |

| Durability | More durable and resistant to impact and moisture. | Less durable; susceptible to damage and moisture unless treated. |

| Cost | Generally lower material cost but higher labor cost. | Higher material cost; labor cost is lower. |

| Use Cases | Ideal for new constructions requiring strong, lasting walls. | Preferred in renovations or fast-track projects. |

Introduction to Plastering Methods

Wet plastering involves applying a mixture of cement, sand, and water directly onto walls for a smooth, durable finish, commonly used in traditional construction. Dry plastering uses pre-made plasterboards fixed to walls or ceilings, offering faster installation and less mess, ideal for renovations and modern builds. Each method caters to different project needs, balancing factors like drying time, surface texture, and labor intensity.

What is Wet Plastering?

Wet plastering involves applying a mixture of water, sand, and cement directly onto walls or ceilings in a damp, malleable state that hardens as it dries. This technique creates a smooth, durable surface that adheres firmly to substrates, ensuring long-lasting protection and aesthetics. Commonly used in traditional construction, wet plastering requires skilled labor and adequate drying time to prevent cracks and ensure a strong finish.

What is Dry Plastering?

Dry plastering is a technique that involves fixing pre-mixed plasterboards or panels onto walls and ceilings without using water or wet mixtures. This method offers faster installation, reduced drying times, and less mess compared to traditional wet plastering, making it ideal for renovations and projects requiring minimal disruption. Dry plastering also provides enhanced thermal and acoustic insulation properties due to the materials used in the plasterboard.

Key Differences: Wet Plastering vs Dry Plastering

Wet plastering involves applying a mixture of cement, sand, and water directly onto surfaces, creating a hard, durable finish after drying. Dry plastering uses pre-fabricated panels or boards, such as gypsum or plasterboard, attached to walls, offering faster installation and less mess. Key differences include drying time, durability, and installation methods, with wet plaster providing a more robust surface and dry plaster allowing easier repairs and insulation integration.

Material Requirements and Preparation

Wet plastering requires a mixture of sand, cement, lime, and water, demanding thorough blending to achieve a consistent, workable paste, while dry plastering involves gypsum or lime-based boards that need minimal preparation beyond cutting and fixing. The wet plaster method necessitates surface dampening and scratch coats for better adhesion, contrasting with dry plastering, which relies on mechanical fixing to rigid substrates without moisture. Material storage and handling also differ significantly, as wet plaster mix has a limited working time, whereas dry plaster boards allow for easier transport and on-site adjustments.

Application Process Comparison

Wet plastering involves applying a mixture of water, sand, and cement or lime directly to walls, requiring skilled troweling and layering to achieve a smooth finish. Dry plastering uses pre-made plasterboards fixed onto walls with adhesive or screws, significantly reducing drying time and minimizing mess on-site. Wet plastering offers better adhesion on uneven surfaces, while dry plastering is faster and allows for easier installation and repairs.

Surface Finish and Durability

Wet plastering delivers a smooth, seamless surface finish that enhances wall aesthetics and provides strong adhesion, making it ideal for high-impact areas. Dry plastering, involving pre-made boards, offers a consistent finish with quicker application but may lack the same durability under heavy wear or moisture exposure. Surface finish quality and long-term resilience depend on project requirements, with wet plaster excelling in longevity and dry plaster favored for speed and ease.

Cost and Time Efficiency

Wet plastering generally incurs higher costs due to materials like sand, cement, and water, as well as longer drying times, which can extend project duration. Dry plastering uses pre-made plasterboards that reduce labor time and allow for faster installation, resulting in lower overall costs and quicker project completion. Efficiency in wet plastering is often outweighed by the time-sensitive benefits and budget-friendliness of dry plastering, especially on large-scale projects.

Suitability for Different Projects

Wet plastering offers excellent adhesion and smooth finishes, making it ideal for traditional masonry walls and surfaces requiring durability and waterproofing. Dry plastering suits projects needing faster application, minimal curing time, or work in damp environments, often used in interior partitions and renovations. Choosing between wet and dry plaster depends on factors like substrate type, project timeline, and exposure to moisture.

Which Plastering Method is Best?

Wet plastering offers a smoother, more durable finish ideal for walls requiring a hard, resilient surface, while dry plastering provides quicker application and less drying time, suitable for faster project completion. Wet plaster absorbs sound and moisture better, making it optimal for high-humidity areas, whereas dry plaster limits cracking and is less labor-intensive. Choosing between wet and dry plastering depends on factors like environmental conditions, project timeline, and desired wall finish quality.

Wet Plastering vs Dry Plastering Infographic

materialdif.com

materialdif.com