Casting plaster is designed for creating detailed molds and sculptures due to its quick setting time and strong, durable finish, while finishing plaster is formulated for smooth, even application on walls and ceilings to achieve a flawless surface. Casting plaster typically has a coarser texture and higher density, making it ideal for replication and model work, whereas finishing plaster is finer and easier to sand for seamless decoration. Choosing the appropriate plaster type depends on whether the project requires structural strength and detail or a polished, aesthetic finish.

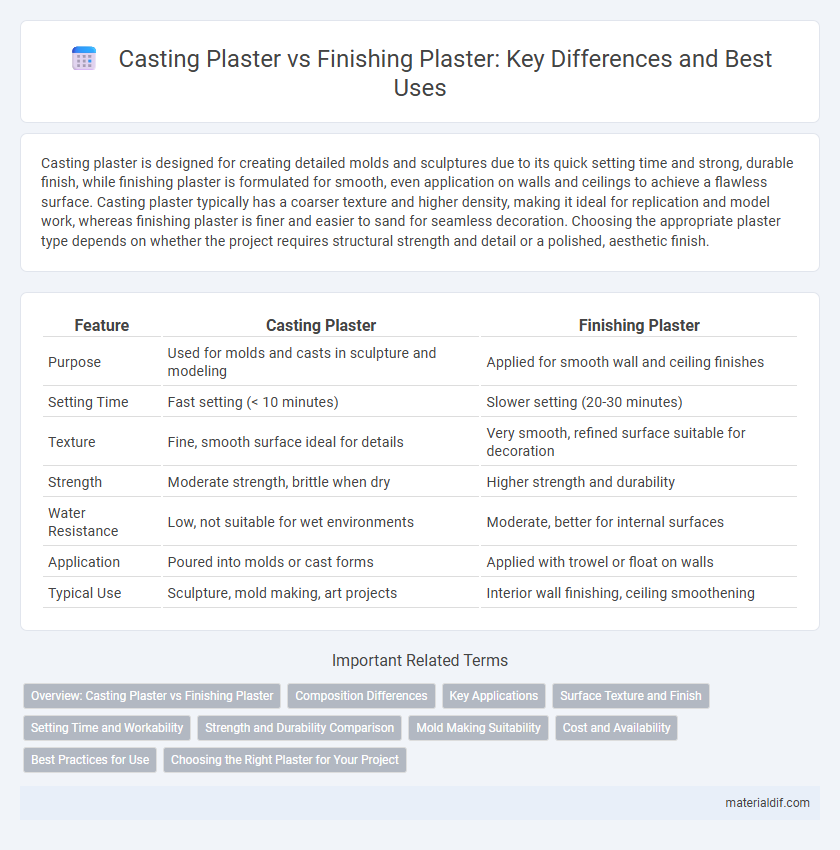

Table of Comparison

| Feature | Casting Plaster | Finishing Plaster |

|---|---|---|

| Purpose | Used for molds and casts in sculpture and modeling | Applied for smooth wall and ceiling finishes |

| Setting Time | Fast setting (< 10 minutes) | Slower setting (20-30 minutes) |

| Texture | Fine, smooth surface ideal for details | Very smooth, refined surface suitable for decoration |

| Strength | Moderate strength, brittle when dry | Higher strength and durability |

| Water Resistance | Low, not suitable for wet environments | Moderate, better for internal surfaces |

| Application | Poured into molds or cast forms | Applied with trowel or float on walls |

| Typical Use | Sculpture, mold making, art projects | Interior wall finishing, ceiling smoothening |

Overview: Casting Plaster vs Finishing Plaster

Casting plaster features a fine, smooth texture ideal for creating detailed molds and sculptures, offering rapid setting times suited for intricate casting work. Finishing plaster has a finer grain and superior adhesion properties, designed to provide a smooth, durable surface for walls and ceilings, enhancing paint and wallpaper application. Both types differ in composition and use, with casting plaster optimized for mold-making and finishing plaster tailored for surface finishing and repair.

Composition Differences

Casting plaster primarily consists of fine, white gypsum powder with minimal additives to ensure smooth flow and fast setting, ideal for molding and replication. Finishing plaster incorporates additives such as retarders, plasticizers, and sometimes lime to enhance workability, adhesion, and surface smoothness for detailed wall or ceiling finishes. The key composition difference lies in casting plaster's purity for strength and quick set, while finishing plaster balances workability and durability for decorative applications.

Key Applications

Casting plaster is primarily used for creating molds and decorative objects due to its quick setting time and smooth finish, ideal for detailed replicas and artistic projects. Finishing plaster, with its finely graded texture and slower drying properties, is best suited for coating walls and ceilings to achieve a smooth, durable surface. Both types are essential in construction and art, with casting plaster excelling in mold-making and finishing plaster enhancing interior wall aesthetics.

Surface Texture and Finish

Casting plaster offers a smooth surface texture ideal for detailed molds and sculptural work due to its fine grain and quick setting properties. Finishing plaster provides a slightly coarser texture designed to create a durable, paint-ready finish on walls and ceilings. The difference in final finish quality directly impacts the choice between the two for either intricate casting or surface preparation in construction.

Setting Time and Workability

Casting plaster offers a rapid setting time, typically hardening within 10 to 15 minutes, which enables quick mold creation but limits extended workability. Finishing plaster, in contrast, sets slower, usually around 20 to 30 minutes, providing a smoother surface finish and more time for detailed application and adjustments. The choice between casting and finishing plaster depends on project requirements for speed versus surface texture precision.

Strength and Durability Comparison

Casting plaster exhibits lower strength and durability compared to finishing plaster due to its finer particle size and faster setting time, making it suitable for lightweight molds and decorative pieces. Finishing plaster, with its higher compressive strength and denser composition, offers superior durability, ideal for protective wall coatings and refined surface finishes. The enhanced structural integrity of finishing plaster supports long-term wear resistance and impact tolerance in construction applications.

Mold Making Suitability

Casting plaster is specifically formulated for mold making due to its fast setting time and ability to capture fine details with high precision. Finishing plaster, while smoother and ideal for final surface coatings, lacks the hardness and durability required for repeated mold use. Choosing casting plaster ensures superior mold accuracy and strength in sculpting and replication projects.

Cost and Availability

Casting plaster generally costs more due to its higher purity and finer grind, making it ideal for detailed molds and sculptures, while finishing plaster is more affordable and widely available, suited for smoothing walls and ceilings. Availability of casting plaster can be limited in standard hardware stores and may require specialty suppliers, whereas finishing plaster is commonly stocked and easier to source for general construction needs. Budget constraints and project requirements significantly influence the choice between the pricier, less accessible casting plaster and the economical, readily obtainable finishing plaster.

Best Practices for Use

Casting plaster requires precise mixing ratios and rapid application to achieve smooth, detailed molds, making it ideal for sculptures and intricate casts. Finishing plaster demands a more controlled application with multiple thin layers that are carefully smoothed and sanded to create a flawless final surface on walls or ceilings. Proper surface preparation, temperature control, and curing time are essential best practices for both types to ensure durability and optimal finish quality.

Choosing the Right Plaster for Your Project

Casting plaster offers a rapid-setting, high-strength option ideal for molds and intricate shapes, while finishing plaster provides a smoother texture suited for final wall coatings and decorative surfaces. Selecting the right plaster depends on project requirements such as durability, drying time, and desired surface finish. Understanding these differences ensures optimal performance and aesthetic quality in both construction and artistic applications.

Casting Plaster vs Finishing Plaster Infographic

materialdif.com

materialdif.com