Manual plastering offers greater precision and control, making it ideal for intricate surfaces and small-scale projects. Machine plastering significantly accelerates the application process and ensures uniform thickness, suitable for large-scale construction sites. Choosing between the two methods depends on project size, surface complexity, and labor availability.

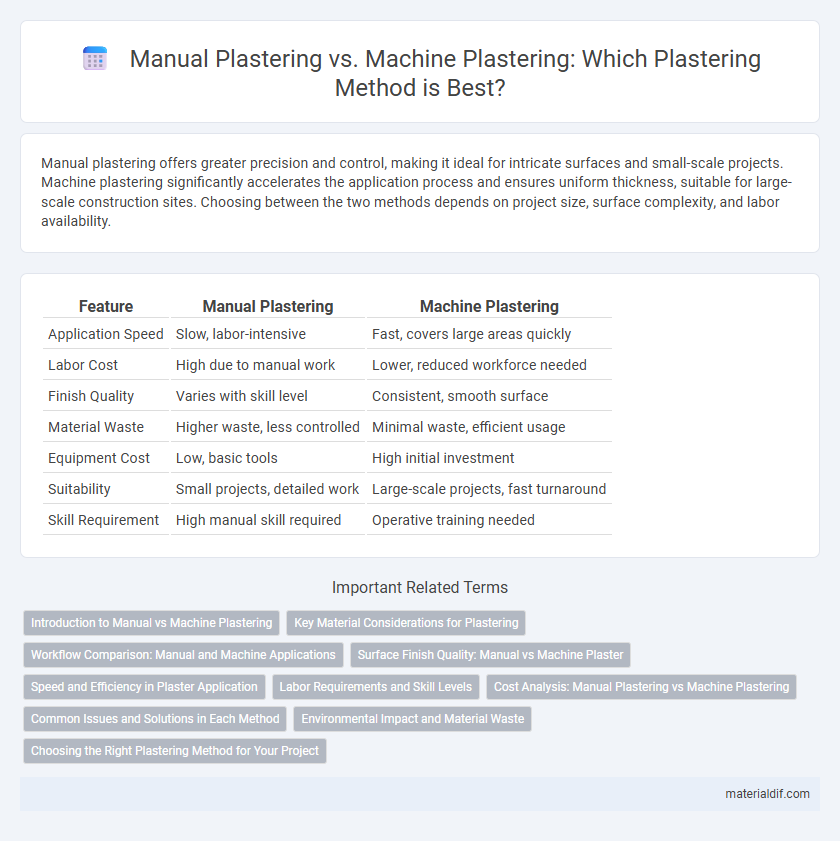

Table of Comparison

| Feature | Manual Plastering | Machine Plastering |

|---|---|---|

| Application Speed | Slow, labor-intensive | Fast, covers large areas quickly |

| Labor Cost | High due to manual work | Lower, reduced workforce needed |

| Finish Quality | Varies with skill level | Consistent, smooth surface |

| Material Waste | Higher waste, less controlled | Minimal waste, efficient usage |

| Equipment Cost | Low, basic tools | High initial investment |

| Suitability | Small projects, detailed work | Large-scale projects, fast turnaround |

| Skill Requirement | High manual skill required | Operative training needed |

Introduction to Manual vs Machine Plastering

Manual plastering involves skilled labor applying plaster by hand using trowels and hawks, allowing for intricate detailing and customization on small-scale projects. Machine plastering employs advanced spraying equipment to deliver plaster quickly and uniformly over large surfaces, improving efficiency and reducing labor costs. Choosing between manual and machine plastering depends on project size, complexity, desired finish quality, and budget constraints.

Key Material Considerations for Plastering

Manual plastering requires precise control over the mix ratio of cement, sand, and water to ensure optimal adhesion and durability, with lime often added to improve workability and breathability. Machine plastering depends on consistent, ready-mixed plaster materials tailored for pump application, emphasizing the importance of uniform particle size and moisture content to prevent clogging and ensure smooth application. Both methods necessitate careful selection of plaster materials based on surface type, environmental conditions, and desired finish quality to achieve long-lasting and efficient plastering results.

Workflow Comparison: Manual and Machine Applications

Manual plastering involves skilled labor applying plaster layer by layer, offering precise control over texture and thickness but requiring more time and physical effort. Machine plastering uses mechanical pumps to deliver and spread plaster rapidly across large surfaces, significantly increasing efficiency and consistency for extensive projects. The workflow contrast highlights manual plastering's suitability for detailed, smaller areas, whereas machine plastering excels in high-volume applications with uniform finish requirements.

Surface Finish Quality: Manual vs Machine Plaster

Manual plastering delivers a highly detailed surface finish due to skilled craftsmanship, allowing for precise control over texture and smoothness. Machine plastering provides a consistent and uniform finish at a faster rate but may lack the finer nuances achievable by hand application. Choosing between manual and machine plastering impacts the overall aesthetic quality, with manual techniques favored for intricate surfaces and machine methods suited for large-scale, uniform wall surfaces.

Speed and Efficiency in Plaster Application

Manual plastering involves skilled artisans applying plaster by hand, which allows for detailed control but typically results in slower completion times and increased labor costs. Machine plastering uses automated equipment to spray plaster onto surfaces rapidly, significantly enhancing speed and overall efficiency by covering large areas uniformly in a fraction of the time. Contractors prefer machine plastering for large-scale projects to meet tight deadlines while maintaining consistent application thickness and reducing labor-intensive processes.

Labor Requirements and Skill Levels

Manual plastering demands skilled laborers with precise craftsmanship to ensure smooth surfaces, requiring significant time and physical effort. Machine plastering reduces labor intensity by automating the application process, allowing less-skilled operators to achieve consistent plaster layers efficiently. The shift from manual to machine plastering optimizes workforce deployment, minimizing dependency on highly trained plasterers while enhancing productivity.

Cost Analysis: Manual Plastering vs Machine Plastering

Manual plastering often involves higher labor costs due to the extended time and skilled workforce required, while machine plastering reduces labor expenses by accelerating the application process. Machine plastering typically lowers material wastage and improves consistency, contributing to overall cost savings despite the initial investment in equipment. The choice between manual and machine plastering ultimately depends on project scale, budget constraints, and desired finish quality.

Common Issues and Solutions in Each Method

Manual plastering often faces common issues such as uneven surface finishes, inconsistent thickness, and longer completion times, which can be mitigated by skilled labor and proper mixing techniques. Machine plastering may encounter challenges like nozzle clogging, equipment malfunction, and difficulty in controlling plaster consistency, solvable by regular maintenance, correct calibration, and using recommended plaster materials. Both methods benefit from thorough training and quality control to ensure durable, smooth, and aesthetically pleasing wall surfaces.

Environmental Impact and Material Waste

Manual plastering typically generates higher material waste due to inconsistent mixing and application, increasing environmental burden through excess raw material consumption. Machine plastering ensures precise mixing and application ratios, significantly reducing excess plaster waste and minimizing resource depletion. The reduced waste and efficiency in machine plastering contribute to lower environmental impact, promoting sustainable construction practices.

Choosing the Right Plastering Method for Your Project

Manual plastering offers precise control and is ideal for intricate or small-scale projects where attention to detail is paramount. Machine plastering significantly speeds up application, making it suitable for large surfaces and projects with tight deadlines, also reducing labor costs. Evaluating project size, surface complexity, and budget constraints helps determine the most efficient plastering method to ensure quality and timely completion.

Manual plastering vs Machine plastering Infographic

materialdif.com

materialdif.com